A kind of preparation method of thermally vulcanized fluorosilicone rubber raw rubber

A fluorosilicone rubber, thermal vulcanization technology, applied in the field of organic chemical industry, can solve the problems of wide molecular weight distribution, difficult mass and heat transfer, low vinyl content, etc., and achieves low polymerization reaction temperature, simple and effective reaction, and shortened neutralization time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

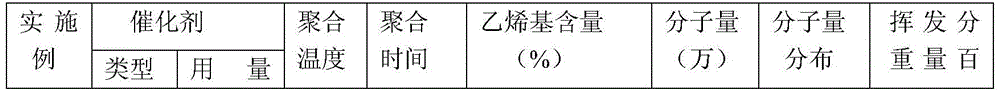

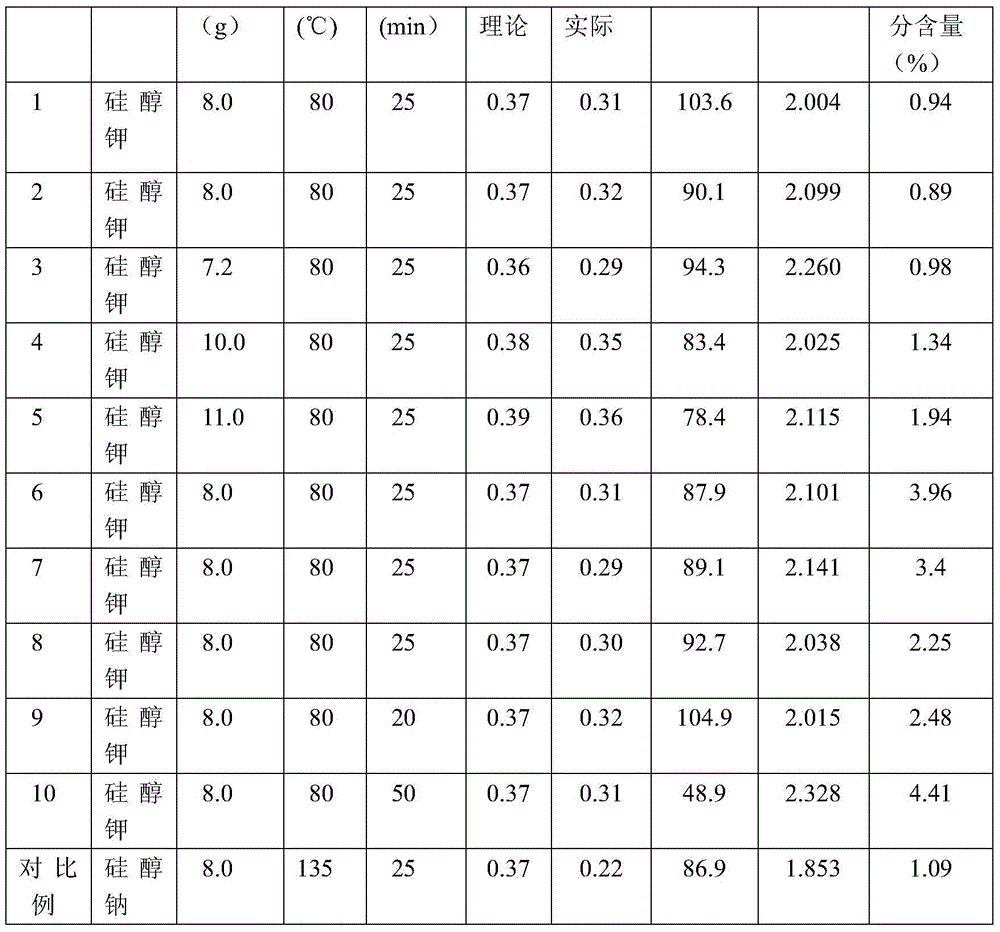

Examples

Embodiment 1

[0039] A preparation method of thermally vulcanized fluorosilicone rubber raw rubber, comprising the following steps:

[0040] (1) The reactor was first ventilated with nitrogen for 1 hour, and then evacuated for 1.5 hours; 2 g of potassium hydroxide was ground into powder, and then mixed with 198.9 g of octamethylcyclotetrasiloxane (D 4 ) and 1.1g of tetramethyldivinyldisiloxane were mixed and reacted at 55°C for 2.5h to obtain a potassium silanolate catalyst prepolymer;

[0041] (2) Add 2000gD 3 F and 4gD 4 Add Vi into the reaction kettle, dehydrate at 50°C and a vacuum of -0.0096MPa for 1h, raise the temperature to 80°C, blow nitrogen, then add 8.0g of the potassium silanolate catalyst prepolymer prepared in step (1), stir and polymerize React for 25 minutes;

[0042] (3) After the polymerization reaction is completed, pass CO 2 And add 1.84g of silicon-based phosphate for neutralization; use pH test paper to detect neutrality to stop CO2 2 ;

[0043] (4) Rapidly rais...

Embodiment 2

[0045] A preparation method of thermally vulcanized fluorosilicone rubber raw rubber, the steps are the same as in Example 1, except that in step (2), after dehydration for 1 hour, the temperature is raised to 80°C, vacuumized, stirred for 25 minutes, and the vacuum degree is -0.006MPa.

Embodiment 3

[0047] A preparation method of thermally vulcanized fluorosilicone rubber raw rubber, comprising the following steps:

[0048] (1) The reaction kettle was first ventilated with nitrogen for 1 hour, and then evacuated for 1.5 hours; 2 g of potassium hydroxide was ground into powder, and then mixed with 198.9 g of octamethylcyclotetrasiloxane (D 4 ) and 1.1g of tetramethyldivinyldisiloxane were mixed and reacted at 55°C for 2.5h to obtain a potassium silanolate catalyst prepolymer;

[0049] (2) 3200gD 3 F and 4gD 4 Add Vi into the reaction kettle, dehydrate for 1 hour at 70°C and a vacuum of -0.01MPa, raise the temperature to 80°C, blow nitrogen, then add 7.2g of the potassium silanolate catalyst prepolymer prepared in step (1), stir and polymerize React for 25 minutes;

[0050] (3) After the polymerization reaction is completed, pass CO 2 And add 1.66g of silicon-based phosphate for neutralization; use pH test paper to detect that it is neutral, and then stop passing CO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com