Monocrystalline silicon non-destructive surface nanometer machining method based on tribo-chemistry induction etching

A nano-fabrication, single crystal silicon technology, applied in the process of producing decorative surface effects, gaseous chemical plating, metal material coating process, etc., can solve the damage of single crystal silicon substrate, limit depth/height, resist etching It can avoid problems such as poor corrosion ability, etc., to achieve the effect of convenient scanning center, avoid friction loss, and simple film making process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A non-damage nanofabrication method on the surface of single crystal silicon based on tribochemically induced etching, the specific operation steps are as follows:

[0028] A, the mass concentration is 98% H 2 SO 4 solution and 30% H 2 o 2 The solution is mixed according to the volume ratio of 7:3 to obtain a mixed solution; the mixed solution is heated to 90°C; then the single crystal silicon that has been passivated by the HF solution is placed in the mixed solution for 30 minutes to make SiO grow on the surface x thin layer; then there will be grown SiO x The thin layer of monocrystalline silicon is taken out and cleaned;

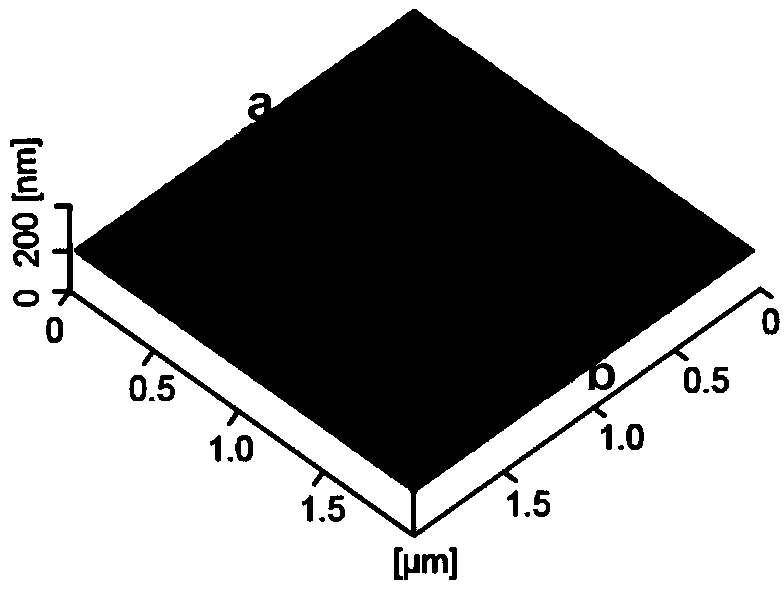

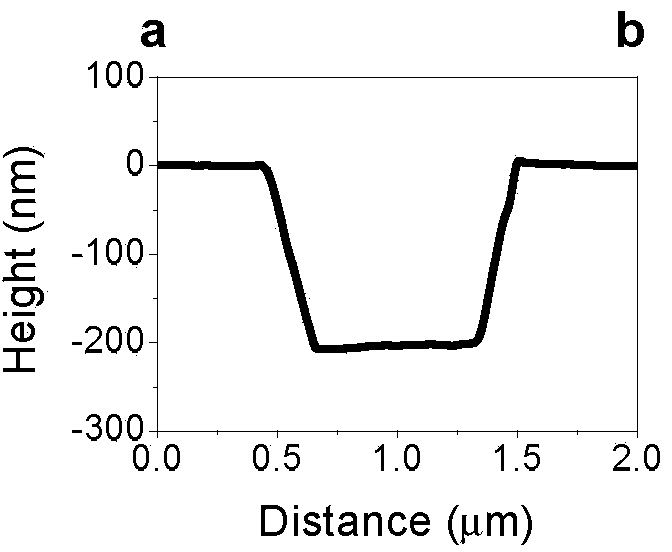

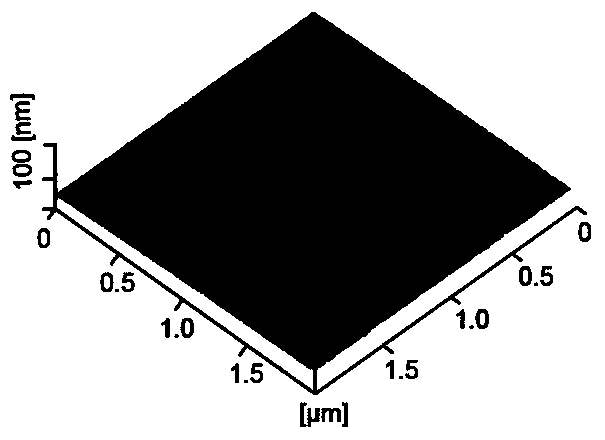

[0029] B. Install the silicon dioxide probe with a spherical tip on the scanning probe microscope, fix the single crystal silicon obtained in step A on the sample stage, start the scanning probe microscope, and control the probe with a contact pressure of 1GPa according to The surface scanning track of 2μm×2μm performs surface scanning on the...

Embodiment 2

[0033] A non-damage nanofabrication method on the surface of single crystal silicon based on tribochemically induced etching, the specific operation steps are as follows:

[0034] A, the mass concentration is 98% H 2 SO 4 solution and 30% H 2 o 2 The solution is mixed according to the volume ratio of 7:3 to obtain a mixed solution; the mixed solution is heated to 90°C; then the single crystal silicon that has been passivated by the HF solution is placed in the mixed solution for 30 minutes to make SiO grow on the surface x thin layer; then there will be grown SiO x The thin layer of monocrystalline silicon is taken out and cleaned;

[0035] B. Install the silicon dioxide probe with a spherical tip on the scanning probe microscope, fix the single crystal silicon obtained in step A on the sample stage, start the scanning probe microscope, and control the probe with a contact pressure of 1GPa according to The surface scanning track of 2μm×2μm performs surface scanning on the...

Embodiment 3

[0039] A non-damage nanofabrication method on the surface of single crystal silicon based on tribochemically induced etching, the specific operation steps are as follows:

[0040] A, the mass concentration is 98% H 2 SO 4 solution and 30% H 2 o 2 The solution is mixed according to the volume ratio of 7:2 to obtain a mixed solution; the mixed solution is heated to 80°C; then the single crystal silicon that has been passivated by the HF solution is placed in the mixed solution for 25 minutes, so that SiO can grow on the surface x thin layer; then there will be grown SiO x The thin layer of monocrystalline silicon is taken out and cleaned;

[0041] B. Install the silicon dioxide probe with a spherical tip on the scanning probe microscope, fix the single crystal silicon obtained in step A on the sample stage, start the scanning probe microscope, and control the probe with a contact pressure of 1GPa according to The surface scanning track of 2μm×2μm performs surface scanning o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com