TC16 titanium alloy bar temperature control continuous rolling method

A TC16 and titanium alloy technology, applied in the field of titanium alloy processing, can solve the problems of large rolling resistance, difficulty in obtaining titanium rods, and large fluctuations in temperature field, etc., achieve slow cooling speed, realize efficient continuous rolling production, and reduce energy consumption The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

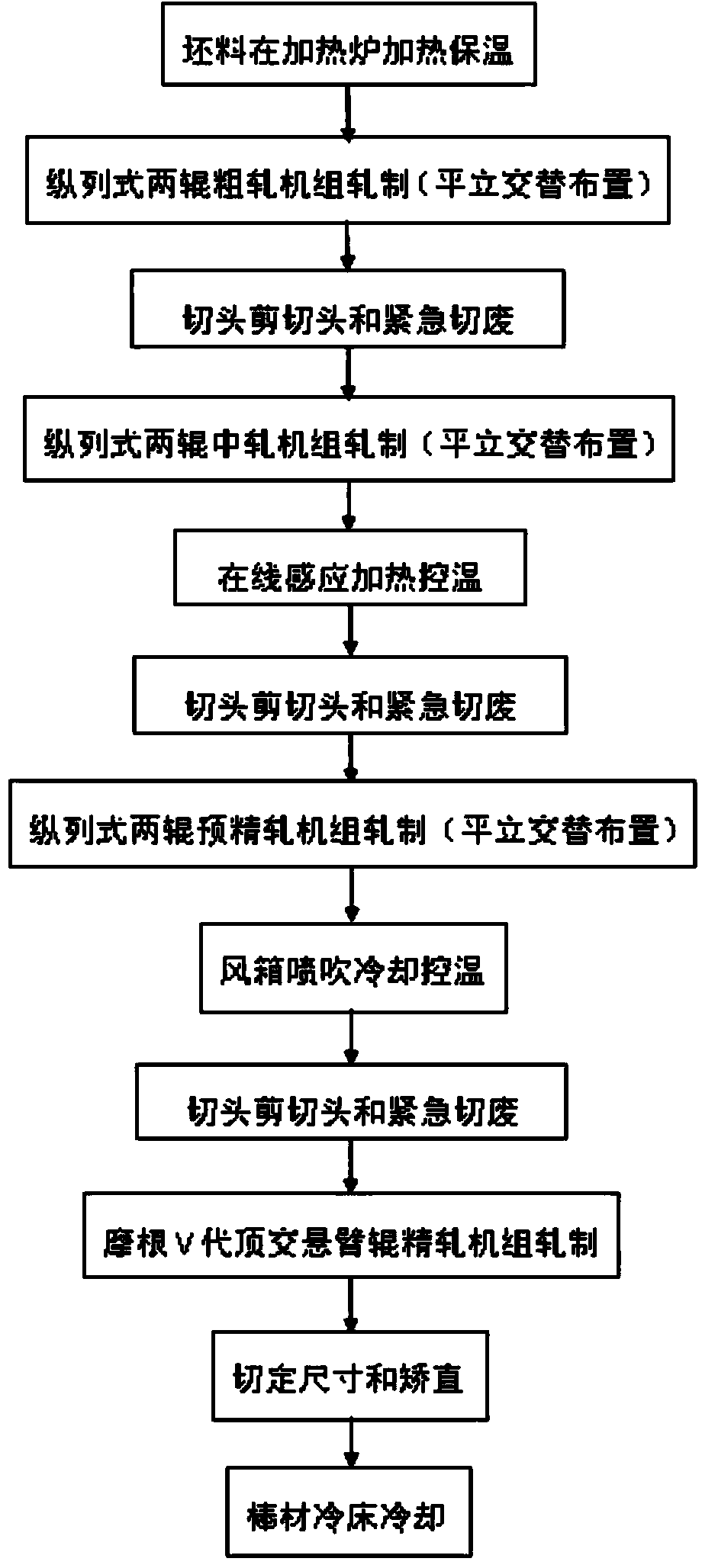

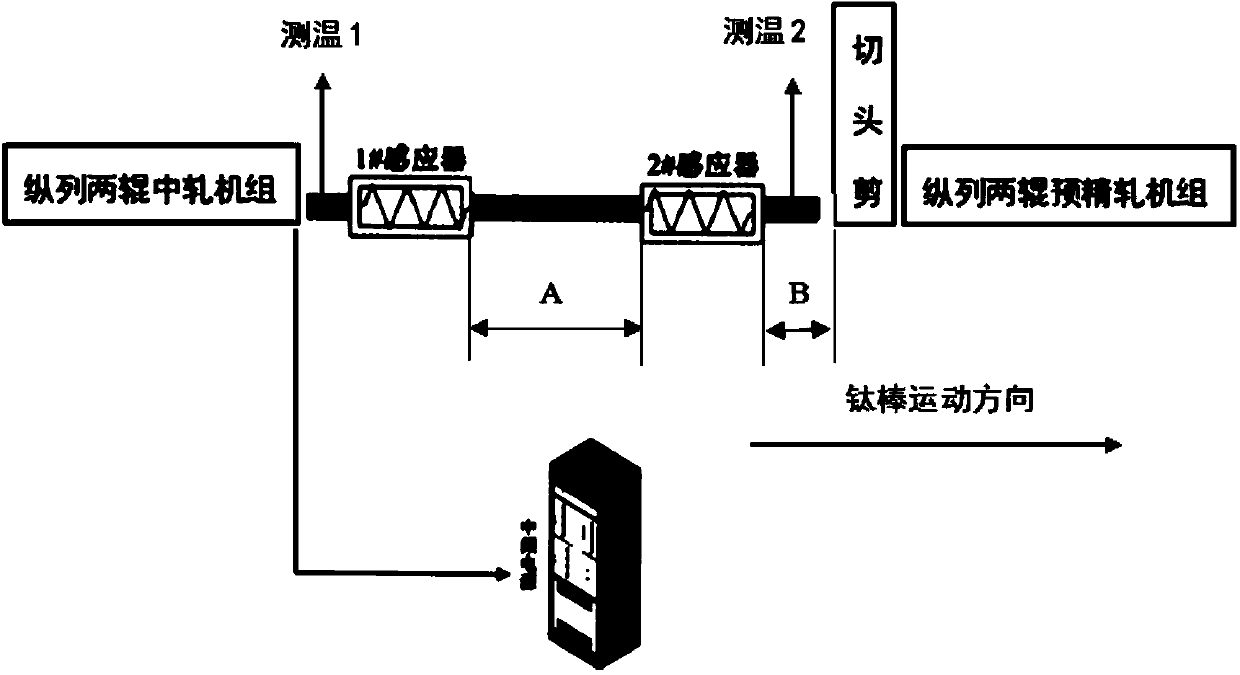

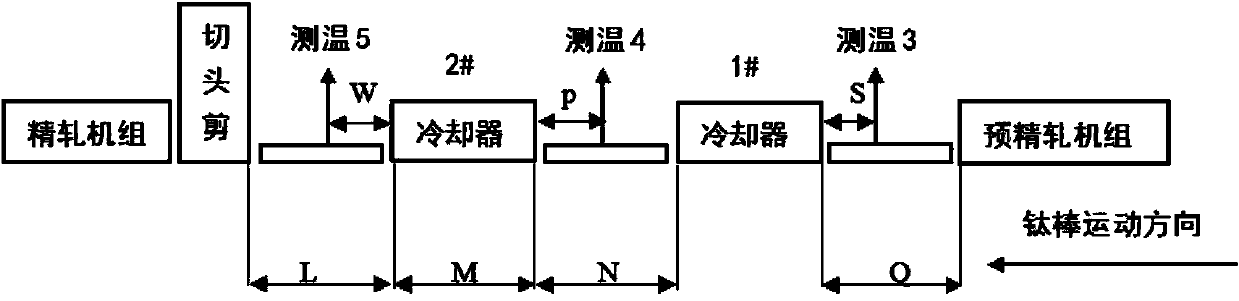

[0030] Attached below figure 1 , 2 , 3, 4, 5, 6, 7, 8 describe embodiments of the present invention.

[0031] The material used for temperature-controlled continuous rolling is TC16 titanium alloy round billet, and its specific chemical composition (wt%) is shown in Table 1.

[0032] Table 1 Chemical composition of TC16 titanium alloy (wt%)

[0033]

[0034]The temperature-controlled continuous rolling technology is to control the microstructure state of the titanium rod during the rolling process and to control the further phase transformation process of the controlled microstructure. Based on the principle of saving components and reducing the amount of the process, high-quality products can be obtained under low-cost conditions. Quality titanium alloy bar products. Aiming at the deficiencies of traditional rolling technology, learn from the controlled rolling and controlled cooling technology (TMCP) and high-speed wire rod production technology in the steel rolling in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com