Coated silicate fluorescent powder and film-coating method thereof

A fluorescent powder and silicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of weak dry powder ball milling coating, easy hydrolysis of silicate fluorescent powder, and affecting performance, etc., to achieve strong water and weather resistance High stability, good stability and firm coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix 3.012g silicate orange red powder and 0.302g silicon dioxide in a ball mill for 30 minutes, then add agate balls with a particle size of 1-3mm and dry grind for 45 minutes. After the powder passes through a 300-mesh sieve, use N 2 Suspended in a small fluidized bed reactor, and then passed into the fluidized bed reactor mixed with 0.031g of trimethylaluminum N 2 , the temperature inside the reactor was 170°C, and after 60 min, a mixture containing 5% O 3 O 2 , reacted for 1 hour, and passed the powder through a 300-mesh sieve to obtain a coated silicate phosphor.

Embodiment 2

[0033] Mix 3.020g of silicate green powder and 0.317g of silicon dioxide in a ball mill for 30 minutes, then add agate balls with a particle size of 1-3mm and dry grind for 45 minutes. After the powder passes through a 300-mesh screen, use N 2 Suspended in a small fluidized bed reactor, and then passed into the fluidized bed reactor mixed with 0.032g of trimethylaluminum N 2 , the temperature inside the reactor was 170°C, and after 60 min, a mixture containing 5% O 3 O 2 , reacted for 1 hour, and passed the powder through a 300-mesh sieve to obtain a coated silicate phosphor.

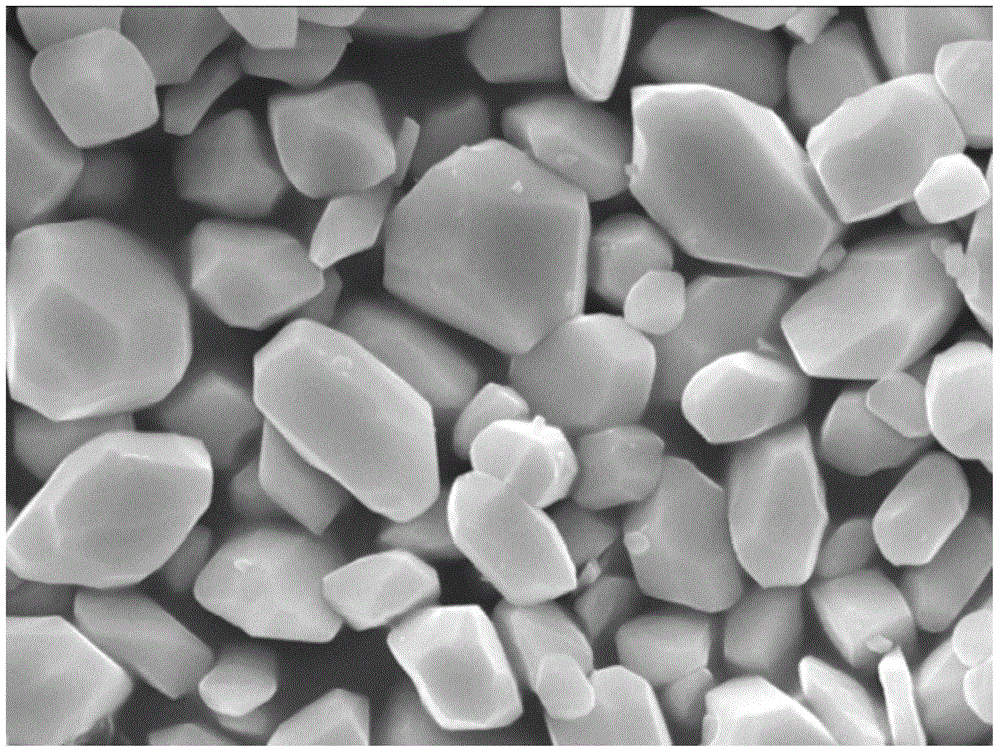

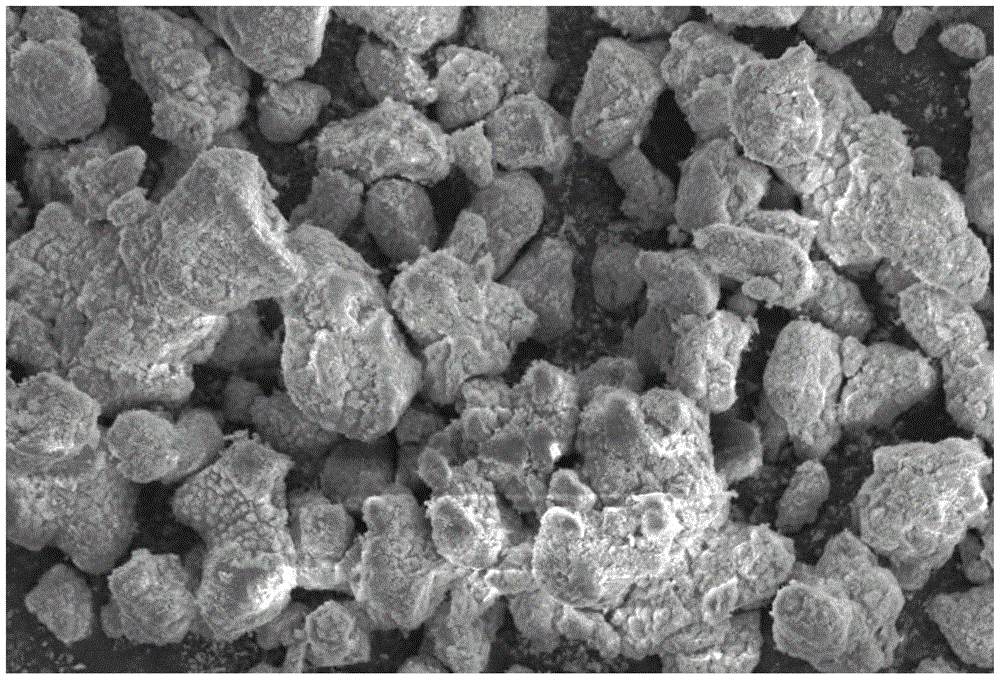

[0034] The scanning electron microscope pictures of silicate green powder before and after coating are as follows: figure 1 and 2 shown. Depend on figure 1 and figure 2 It can be seen that figure 2 coated phosphor with figure 1 The surface of the uncoated phosphor has obvious differences under the scanning electron microscope, and it can be seen that the surface of the phosphor is successfully...

Embodiment 3

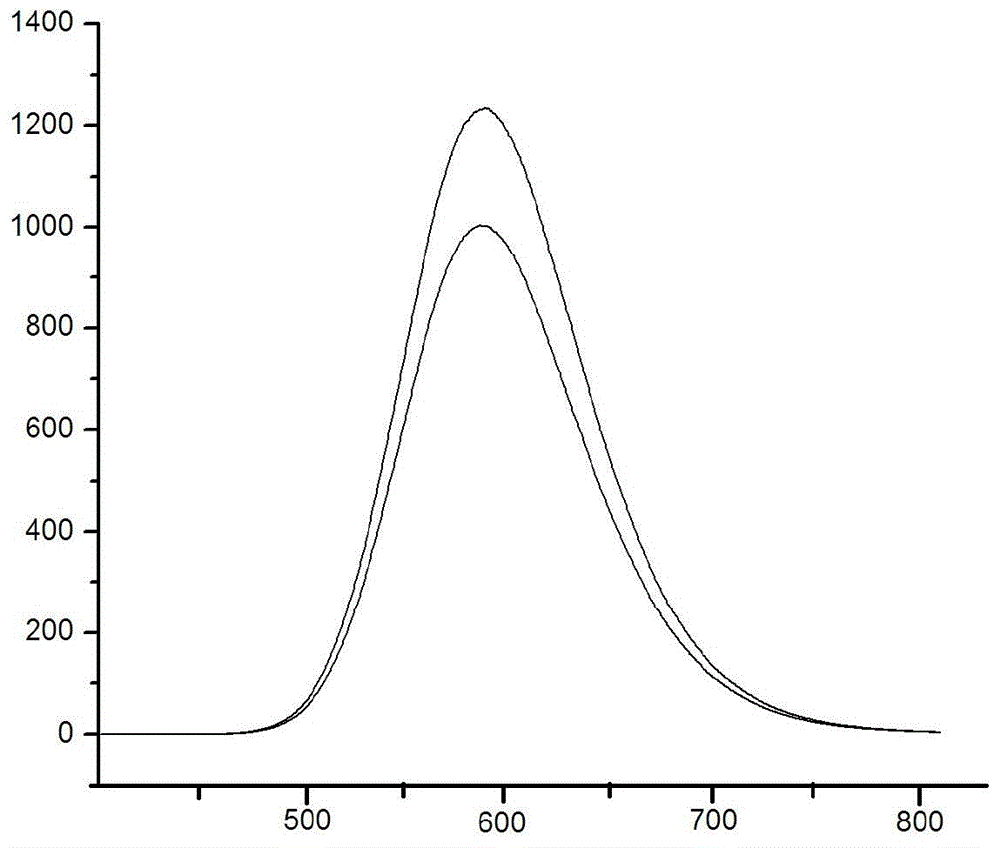

[0036] Mix 4.517g of silicate orange red powder and 0.311g of silicon dioxide in a ball mill for 30 minutes, then add agate balls with a particle size of 1-3mm and dry grind for 60 minutes. After the powder passes through a 250-mesh screen, use N 2 Suspended in a small fluidized bed reactor, and then passed into the fluidized bed reactor mixed with 0.094g trimethylaluminum N 2 , the temperature inside the reactor was 185°C, and after 60 min, a mixture containing 5% O 3 O 2 , reacted for 1 hour, and passed the powder through a 300-mesh sieve to obtain a coated silicate phosphor. Spectra of orange-red silicate phosphor before and after coating image 3 shown.

[0037] Depend on image 3 It can be seen that the orange-red silicate phosphor emits light at 590 nm, and the luminous intensity after coating is higher than that before coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com