Method for preparing (S)-4-hydroxy-2-oxo-1-pyrrolidine acetamide

A technology of pyrrolidineacetamide and hydroxyl, which is applied in the field of preparation of -4-hydroxy-2-oxo-1-pyrrolidineacetamide, and can solve the problems of increasing reaction steps, reducing the total yield, and low synthesis yield , to achieve the effect of short cycle, low toxicity and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

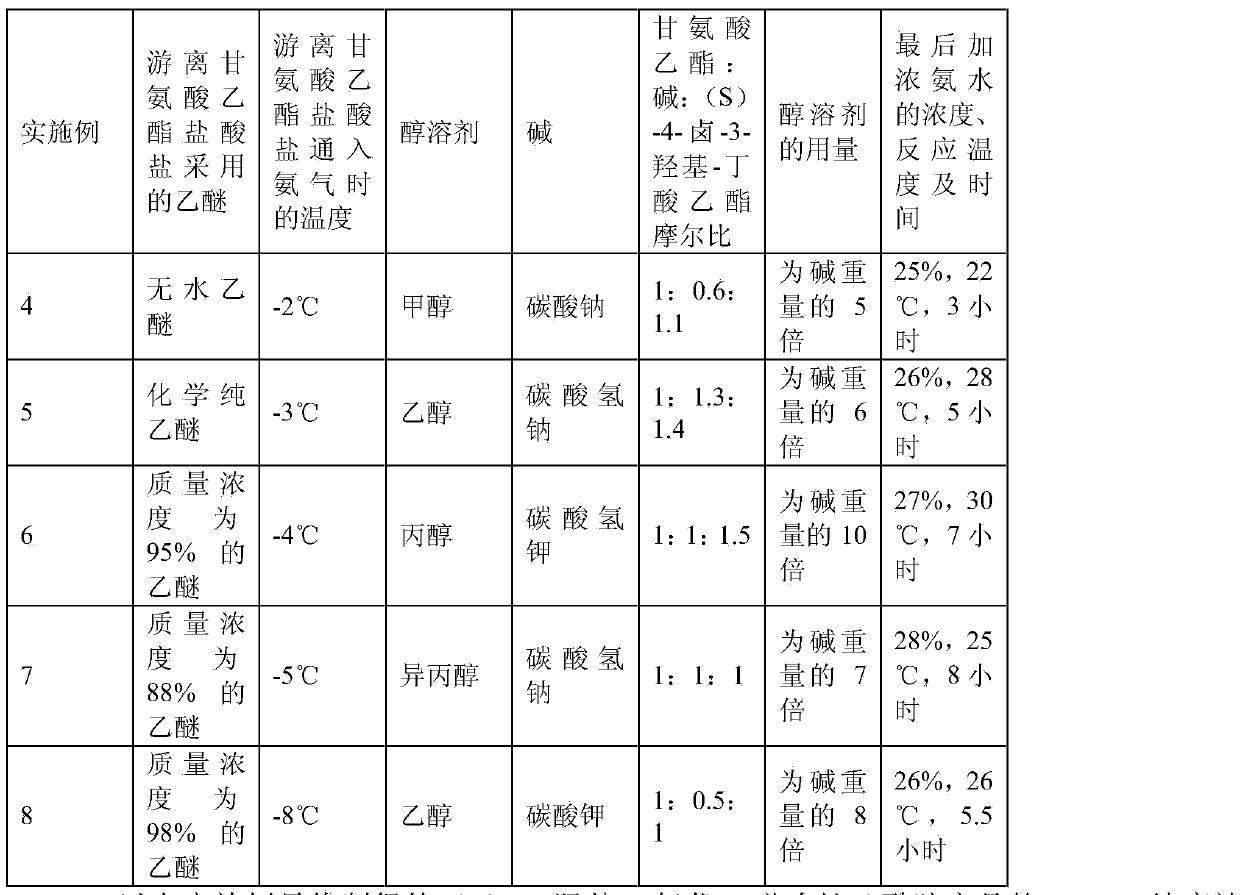

Examples

Embodiment 1

[0023] The preparation method of (S)-4-hydroxy-2-oxo-1-pyrrolidine acetamide is carried out according to the following steps:

[0024] 1. Preparation of crude product:

[0025] (a) 139.6 g of ethyl glycine hydrochloride was added to 1300 ml of anhydrous ether, ice-cooled to -2°C, and 22.1 g of ammonia gas was introduced into it to free ethyl glycine hydrochloride into ethyl glycine, wherein ethyl glycine hydrochloride Salt: anhydrous ether: ammonia is 1mol:1300ml:1.3mol;

[0026] (b) to above-mentioned product, add dehydrated alcohol 672ml, sodium bicarbonate 84.0g, drip (S)-4-chloro-3-hydroxy-butyric acid ethyl ester 250.0g, described dropping time is 2.5 hours, in The pH was 8.2 and the temperature was 66°C for 28 hours;

[0027] (c) filter, fully wash the filtrate with ethanol, concentrate, the concentrate is dissolved in water, and then 7 times of ethyl acetate by weight of the filtrate is added to extract, concentrate the water phase, and separate by column chromatograp...

Embodiment 2

[0034] The preparation method of (S)-4-hydroxy-2-oxo-1-pyrrolidine acetamide is carried out according to the following steps:

[0035] 1. Preparation of crude product:

[0036] (a) glycine ethyl ester hydrochloride is added to anhydrous ether, ice-cooled to 1 ℃ and ammonia gas is introduced to make glycine ethyl ester hydrochloride free into glycine ethyl ester, wherein glycine ethyl ester hydrochloride: anhydrous ether: Ammonia is 1mol:1395ml:1.5mol;

[0037] (b) adding anhydrous methanol, sodium carbonate, (S)-4-iodo-3-hydroxy-butyric acid ethyl ester to the above-mentioned product, at pH8, the temperature is 70 ℃ to react for 30 hours;

[0038] (c) filter, fully wash the filtrate with ethanol, concentrate, the concentrate is water-soluble, and then adds 6 times of methylene chloride by weight of the filtrate to extract, concentrate the water phase, and separate by column chromatography; finally adding mass percent concentration is 25% The ammonia water was reacted at 20 °...

Embodiment 3

[0044] The preparation method of (S)-4-hydroxy-2-oxo-1-pyrrolidine acetamide is carried out according to the following steps:

[0045] 1. Preparation of crude product:

[0046] (a) suspending glycine ethyl ester hydrochloride in chemically pure ether, then introducing ammonia gas to free glycine ethyl ester hydrochloride into glycine ethyl ester;

[0047] (b) in above-mentioned product, add dehydrated alcohol, sodium bicarbonate, drip (S)-4-bromo-3-hydroxy-butyric acid ethyl ester, described time for adding is 3 hours, at pH9, temperature is 65 React at ℃ for 15 to 26 hours;

[0048] (c) filter then, fully wash the filtrate with ethanol, concentrate, the concentrate is soluble in water, and then adds the chloroform of 4 times of filtrate weights to extract, concentrate the aqueous phase, and separate; at last adding mass percent concentration is 25% ammoniacal liquor, in The crude product of (S)-4-hydroxy-2-oxo-1-pyrrolidineacetamide was obtained by reacting at 25°C for 6 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com