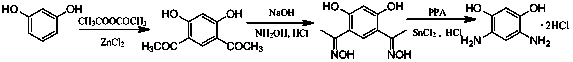

Method for preparing 4,6-diaminoresorcinol dihydrochloride through one-pot synthesis

A technology of diaminoresorcinol hydrochloride and diacetylresorcinol is applied in the field of preparation of 4,6-diaminoresorcinol hydrochloride (DAR·2HCl), which can solve the problem of production efficiency It can improve the efficiency and yield, simplify the process flow, and promote the development of industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

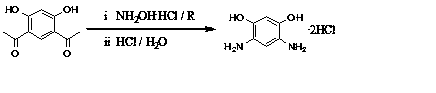

Method used

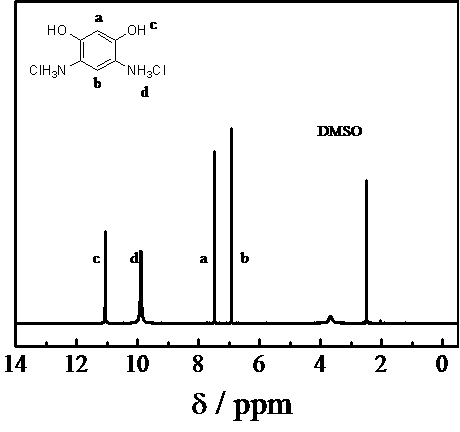

Image

Examples

Embodiment 1

[0019] DAR hydrochloride was prepared by one-pot method at 65℃ and the molar ratio of hydroxylamine hydrochloride / polyphosphoric acid / resorcinol was 2.2 / 3 / 1.

[0020] Weigh polyphosphoric acid (PPA, 15.80g) and 4,6-diacetylresorcinol (3.00g) in a 100mL three-neck flask, add hydroxylamine hydrochloride (2.15g) to it under stirring conditions, and raise the temperature to 65°C, take samples every half hour for HPLC, observe the reaction, after the reaction is complete, cool to room temperature, add hydrochloric acid (6mol / L, 20 mL) and SnCl 2 (0.05g), continue to stir and raise the temperature to 100°C, and react for 2 hours. After cooling in air, the crystals were precipitated, filtered with suction, washed with hydrochloric acid, washed with ethanol, and vacuum-dried in a glass drying oven. The conversion rate was 43.5%.

Embodiment 2

[0022] DAR hydrochloride was prepared by one-pot method under the condition of 80℃ and the molar ratio of hydroxylamine hydrochloride / polyphosphoric acid / resorcinol at 2.2 / 3 / 1.

[0023] Weigh polyphosphoric acid (PPA, 15.80g) and acetyl resorcinol (3.00g) into a 100mL three-necked flask. Under stirring conditions, add hydroxylamine hydrochloride (2.15g) to it, raise the temperature to 80°C, take samples for HPLC every half hour, observe the reaction, after the reaction is completed, cool to room temperature, add hydrochloric acid (6mol / L, 20 mL ) and SnCl 2 (0.05g), continue to stir and raise the temperature to 100°C, and react for 2 hours. After cooling in air, crystals were precipitated, filtered with suction, washed with hydrochloric acid, washed with ethanol, and vacuum-dried in a glass drying oven. The conversion rate was 75.5%.

Embodiment 3

[0025] DAR hydrochloride was prepared by one-pot method at 95°C and the molar ratio of hydroxylamine hydrochloride / polyphosphoric acid / resorcinol was 2.2 / 3 / 1.

[0026] Weigh polyphosphoric acid (PPA, 15.80g) and acetyl resorcinol (3.00g) into a 100mL three-necked flask. Under stirring conditions, add hydroxylamine hydrochloride (2.15g) to it, raise the temperature to 95°C, take samples for HPLC every half hour, observe the reaction, after the reaction is completed, cool to room temperature, add hydrochloric acid (6mol / L, 20 mL ) and SnCl 2(0.05g), continue to stir and raise the temperature to 100°C, and react for 2 hours. After cooling in air, crystals were precipitated, filtered with suction, washed with hydrochloric acid, washed with ethanol, and vacuum-dried in a glass drying oven. The conversion rate was 69.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com