Absorbent capable of simultaneously performing desulfurization, denitrification and VOCs (Volatile Organic Compounds) removal on flue gas as well as preparation and application of absorbent

A desulfurization, denitrification, and absorbent technology, which is applied in the direction of air quality improvement, the use of liquid separation agents, chemical instruments and methods, etc., can solve the problems of being unsuitable for removing biomass flue gas, high investment and operation costs, and difficult operation and management. Achieve the effect of small footprint, simple preparation and use, and simple overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The total flue gas volume of a 35t / h biomass boiler is 60,000 m 3 / h, measured SO in the flue gas before purification 2 The concentration is 600~750mg / m 3 , with an average concentration of 675mg / m 3 ;NO X The concentration is 350~550mg / m 3 , with an average concentration of 450mg / m 3 ; TVOCs concentration is 150-200mg / m 3 , with an average concentration of 175mg / m 3 .

[0042] The absorption tower adopts the high-efficiency absorption tower (ZL200420103291.9) prepared by the existing patented technology: the tower height is 15m, the tower diameter is 3m, and the gas residence time is >4s.

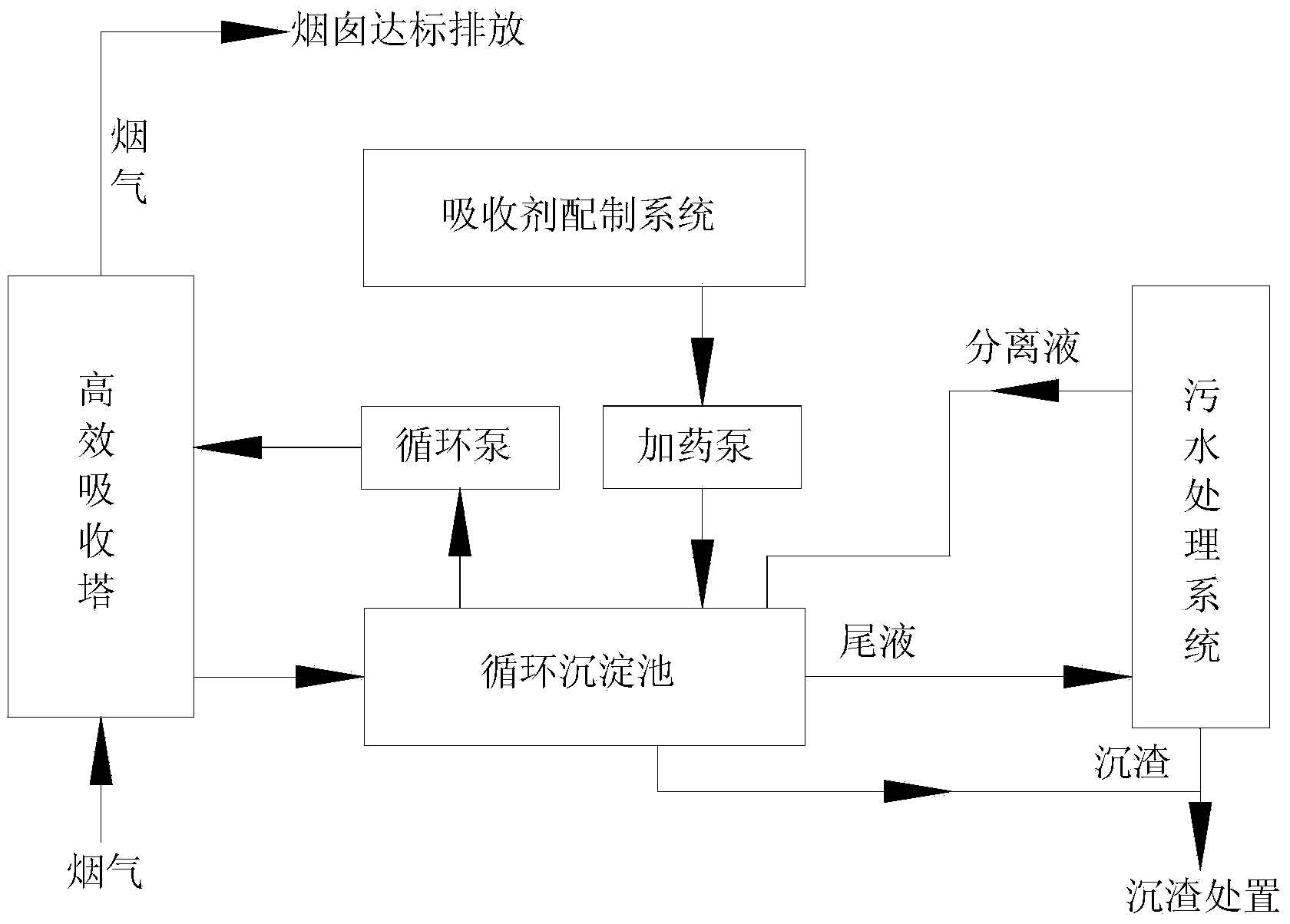

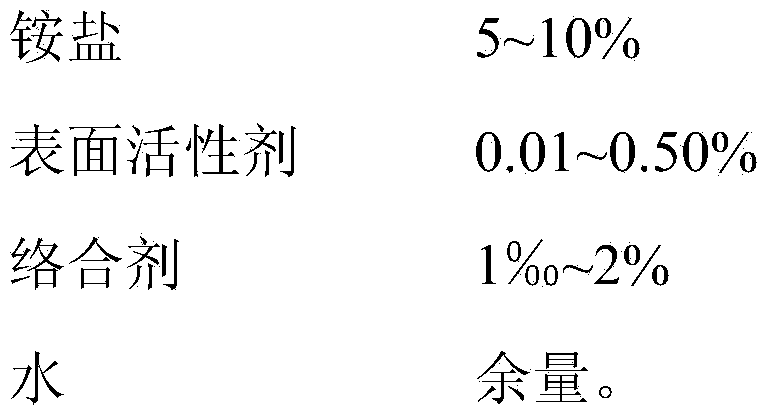

[0043] The process flow of purifying flue gas pollutants is as follows: figure 1 As shown: the flue gas enters the high-efficiency absorption tower from the high-speed swirl at the bottom of the high-efficiency absorption tower; the prepared flue gas simultaneously desulfurizes, denitrates and deVOCs absorbent is added to the circulating sedimentation tank by the dosing pump...

Embodiment 2~7

[0047] The amount of flue gas purified in Examples 2 to 7, the components and concentrations in the flue gas before purification, the absorption tower, and the flue gas purification process are all the same as in Example 1. The preparation method and purification effect of the flue gas simultaneous desulfurization, denitrification and deVOCs absorbent used in the flue gas purification process in each embodiment are shown in Table 1.

[0048] Absorbent preparation, composition and pollutant purification effect in table 1 embodiment 1~7

[0049]

[0050]

[0051] It can be seen from Table 1 that the absorbents prepared in Examples 1 to 7 have a great impact on pollutant SO 2 , NOx, TVOCs all have very good removal effect.

Embodiment 8

[0053] An industrial boiler was mixed with sludge, and the SO in the flue gas before purification was measured 2 The concentration is 800~1100mg / m 3 , with an average concentration of 950mg / m 3 ;NO X The concentration is 500~600mg / m 3 , with an average concentration of 550mg / m 3 ;The concentration of TVOCs is 150-350mg / m 3 , with an average concentration of 250mg / m 3 .

[0054] The absorption tower adopts the high-efficiency absorption tower (ZL200420103291.9) prepared by the existing patented technology: the tower height is 15m, the tower diameter is 3m, and the gas residence time is >4s. Process flow is identical with embodiment 1. The preparation, composition and purification effect of the absorbent are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com