Thin-film solar cell with micron-nanometer two-stage array structure and manufacturing method thereof

A technology of solar cells and array structures, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high cost and low conversion rate of solar cells, and reduce the preparation cost and equipment requirements. The effect is not high and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

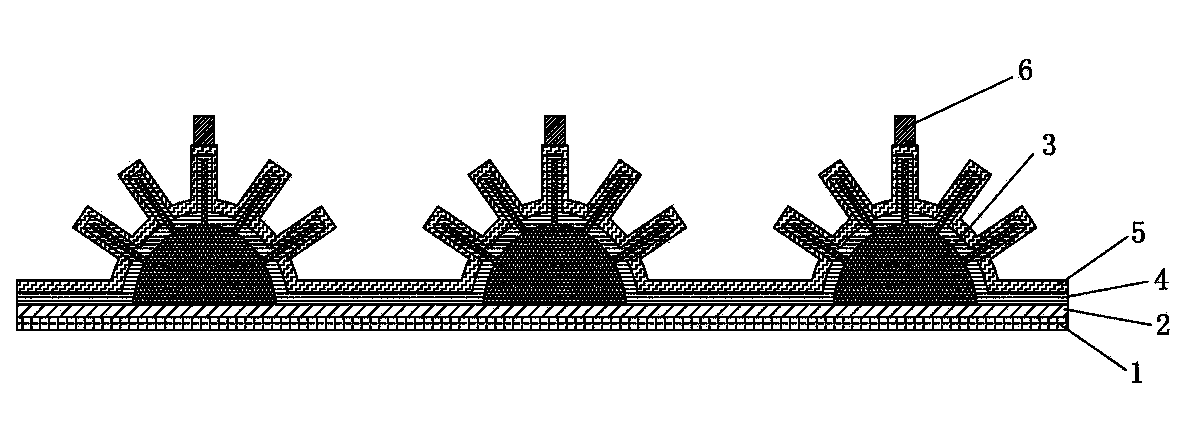

[0032] The preparation method of the micro / nano secondary array structure thin-film solar cell of this embodiment comprises the following steps:

[0033] (1) Polish the copper sheet with sandpaper No. 0-6, and ultrasonically clean it with alcohol, acetone, and deionized water for 5 minutes; then magnetron sputtering a layer of Mo on the copper sheet, and the thickness of Mo is 800nm;

[0034] (2) Pulse electrochemical deposition of a copper film with a thickness of 1 μm on the copper sheet deposited with the Mo layer; then put the copper sheet deposited with the copper film into the oxygen / hydrogen sulfide mixed gas, the volume ratio of oxygen and hydrogen sulfide 1:2, put it at 11°C for 16h, so that the copper film becomes Cu 2 S Micro / Nano Secondary Array, Cu 2 S nanowires have a diameter of 50nm and a length of 10μm; Cu 2 The diameter of the S spherical cap is 8 μm, Cu 2 The interval between the S spherical caps is 2 μm; then the treated copper sheet is placed in an aque...

Embodiment 2

[0041] The preparation method of the micro / nano secondary array structure thin-film solar cell of this embodiment comprises the following steps:

[0042] (1) The glass sheet was ultrasonically cleaned with 1mol / L NaOH, 1mol / L HCl solution, absolute ethanol, and deionized water in sequence, and then a layer of ITO was magnetron sputtered on the glass sheet, and the thickness of ITO was 200nm;

[0043] (2) Electrochemically deposit a layer of copper film with a thickness of 500nm on the glass sheet deposited with ITO at constant voltage; put the glass sheet deposited with copper film into the oxygen / hydrogen sulfide mixed gas, the volume ratio of oxygen and hydrogen sulfide is 1:100, put it at 0°C for 500h to make the copper film into Cu 2 S Micro / Nano Secondary Array, Cu 2 S nanowires have a diameter of 10nm and a length of 100nm; Cu 2 The diameter of the S spherical cap is 100 μm, Cu 2 The interval between the S spherical caps is 50 μm; then place the treated glass sheet in...

Embodiment 3

[0050] The preparation method of the micro / nano secondary array structure thin-film solar cell of this embodiment comprises the following steps:

[0051] (1) Electron beam evaporation of a layer of Mo on the newly cut mica sheet, the thickness of Mo is 800nm;

[0052] (2) A copper film with a thickness of 1 μm was electrochemically deposited on the mica sheet deposited with Mo at a constant current; the mica sheet deposited with the copper film was placed in a mixed gas of oxygen / hydrogen sulfide, and the volume ratio of oxygen and hydrogen sulfide was 1:0.01, put it at 200°C for 12 hours to make the copper film into Cu 2 S Micro / Nano Secondary Array, Cu 2 S nanowires have a diameter of 500nm and a length of 300μm; Cu 2 The diameter of the S spherical cap is 0.5μm, Cu 2 The interval between the S spherical caps is 100 μm; then the treated mica sheet is placed in an aqueous hydrochloric acid solution with a concentration of 0.01mol / L to dissolve the oxide layer generated on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com