Process and device for welding magnesium alloy sheets

A welding device and magnesium alloy technology, applied in welding equipment, welding media, auxiliary devices, etc., can solve the problems of affecting the welding fusion degree of magnesium alloys, affecting the appearance of magnesium alloy surfaces, and high hardness and brittleness, so as to improve the welding fusion degree and surface Quality, reduce oxidation slag inclusion, improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

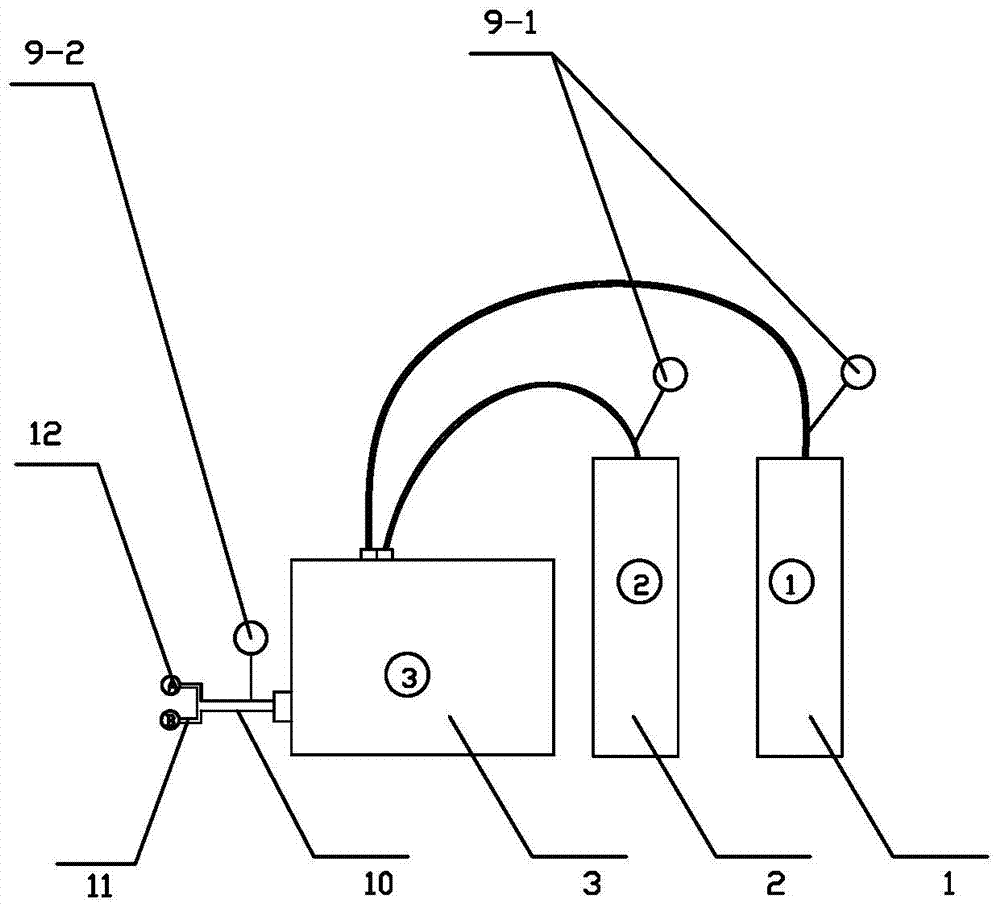

[0024] In this embodiment, a welding process for magnesium alloy plates is performed using argon gas with a volume percentage of 70-80% and helium gas with a volume percentage of 20-30% for protective welding; the process is as follows:

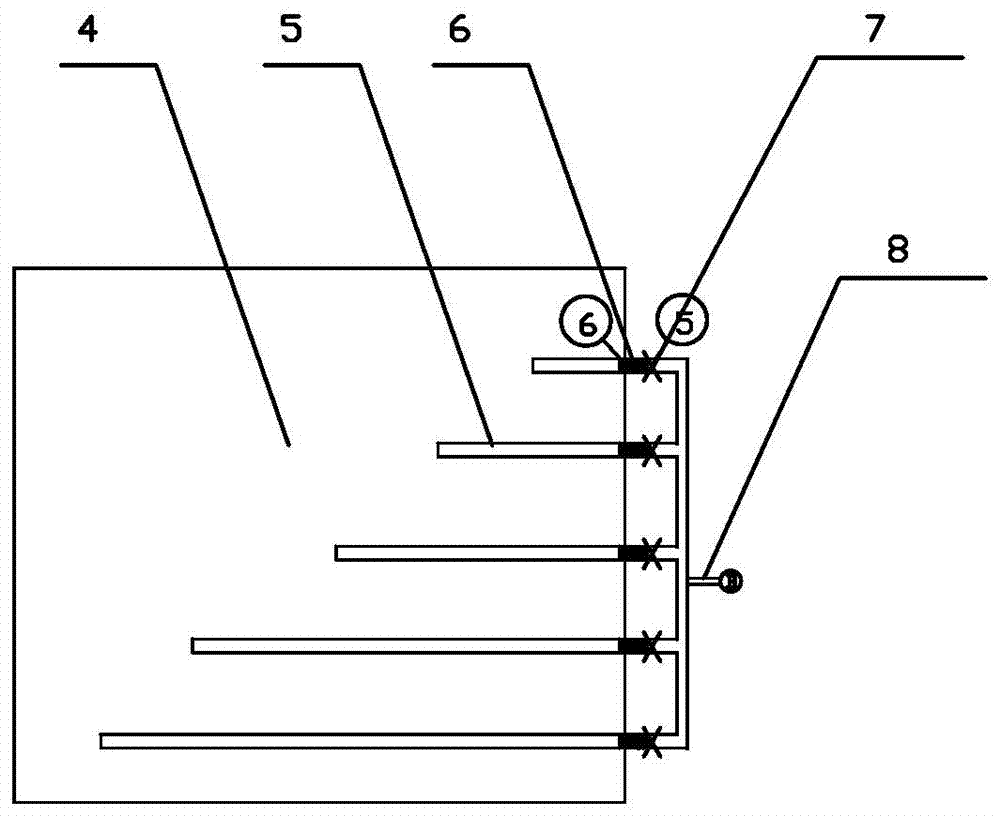

[0025] Control the pressure gauge (9) at the mouth of the argon and helium cylinders during welding, and flow into the gas mixer (3) according to the volume ratio of 70-80% argon and 20-30% helium; The length of the groove (5) of the welding platform (4) is selected so that the length of the groove (5) is 10-30mm longer than the length of the weld; when welding, open the inlet pipe valve (7) corresponding to the selected groove (5), and close the The selected groove (5) corresponds to the intake pipe valve (7), and the magnesium plate is docked above the selected groove (5), and welding can be performed when the ventilation time exceeds 5 seconds.

[0026] The magnesium alloy plate welding device includes a welding platform (4), a groove (5) ...

Embodiment 2

[0034] A kind of welding process of magnesium alloy plate in this embodiment, the process is as follows:

[0035] Control the pressure gauge (9) at the mouth of the argon and helium cylinders during welding, and flow into the gas mixer (3) according to the volume ratio of 70% argon and 30% helium; select the welding platform according to the length of the weld seam of the magnesium plate (4) of the groove (5), so that the length of the groove (5) is greater than the length of the weld by 15mm; when welding, open the corresponding intake pipe valve (7) of the selected groove (5), and close the unselected groove (5) ) corresponding to the intake pipe valve (7), butt the magnesium plate above the selected groove (5), and weld it when the ventilation time exceeds 5 seconds.

[0036] The magnesium alloy plate welding device includes a welding platform (4), a groove (5) is set on the welding platform (4), and one end of the groove (5) is connected through a copper tube (6), and the ...

Embodiment 3

[0044] In this embodiment, a welding process for magnesium alloy plates is performed using argon gas with a volume percentage of 70-80% and helium gas with a volume percentage of 20-30% for protective welding; the process is as follows:

[0045] Control the pressure gauge (9) at the mouth of the argon and helium cylinders during welding, and flow into the gas mixer (3) according to the volume ratio of 70-80% argon and 20-30% helium; The length of the groove (5) of the welding platform (4) is selected so that the length of the groove (5) is 10-30mm longer than the length of the weld; when welding, open the inlet pipe valve (7) corresponding to the selected groove (5), and close the The selected groove (5) corresponds to the intake pipe valve (7), and the magnesium plate is docked above the selected groove (5), and welding can be performed when the ventilation time exceeds 5 seconds.

[0046] The magnesium alloy plate welding device includes a welding platform (4), a groove (5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com