Self-focusing ultrasonic transducer based on Fresnel wave-zone piezoelectric composite material

A piezoelectric composite material and Fresnel wave band technology, applied in the direction of fluid using vibration, etc., can solve the problems of complex production of focused ultrasonic transducers, high process precision requirements, and high production costs, and achieve electrode connection and packaging. The effect of good focusing performance and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

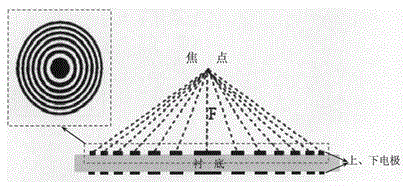

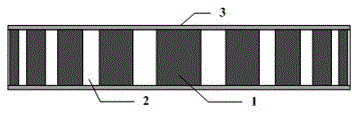

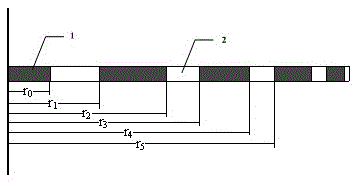

[0037] refer to Figure 1-Figure 8 As shown, the self-focusing ultrasonic transducer based on the Fresnel-zone piezoelectric composite material includes the Fresnel-zone piezoelectric composite material, and the Fresnel-zone piezoelectric composite material is provided with The matching layer 4, the metal wire 9 is arranged under the Fresnel-zone piezoelectric composite material, the backing 6 is below the metal wire 9, and the bottom tray 7 is on both sides below the backing 6, The two bottom trays 7 are insulating epoxy resin 8, and both sides of the Fresnel-zone piezoelectric composite material and the backing 6 are also insulating epoxy resin 8, so The exterior of the ultrasonic transducer is a conductive shell 5.

[0038] Further, the Fresnel-zone piezoelectric composite material includes a piezoelectric ceramic 1, an epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com