High-multiplying-power flexibly-packaged lithium ion secondary battery and preparation method thereof

A secondary battery and flexible packaging technology, which is applied in secondary battery, electrolyte storage battery manufacturing, battery electrodes, etc., can solve the problems of increasing battery heat generation, slowing down the electrochemical reaction area and reaction speed of electrodes, and increasing battery internal resistance, etc. Achieve the effects of reducing heat generation, improving high-current discharge capacity, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

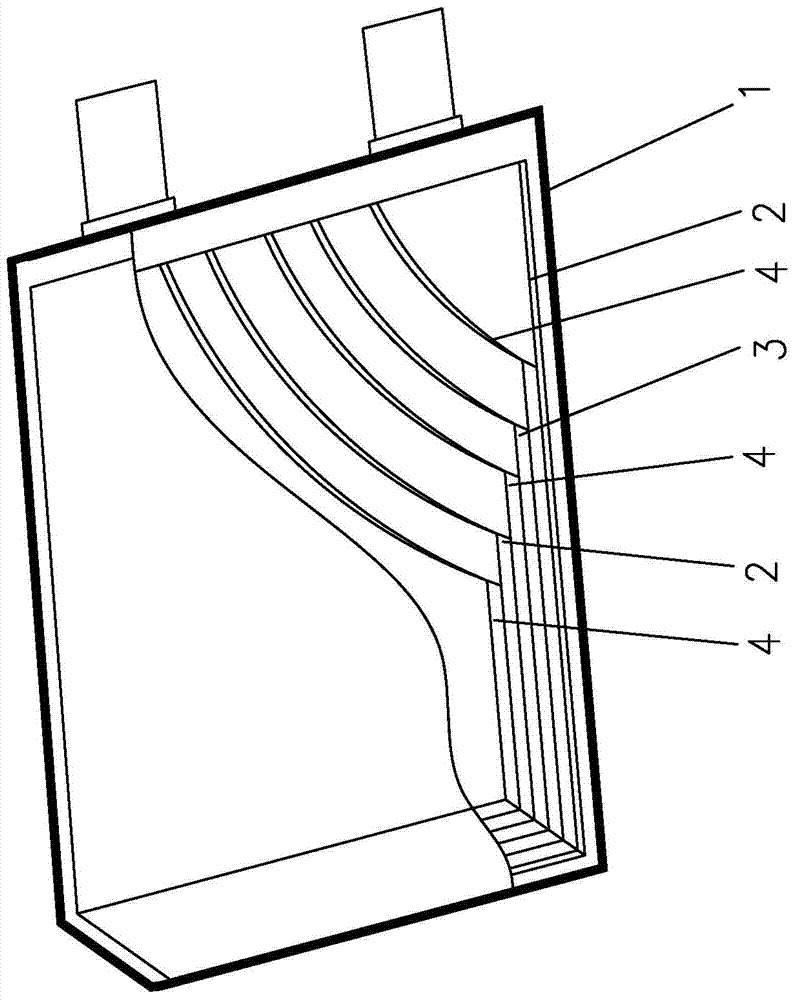

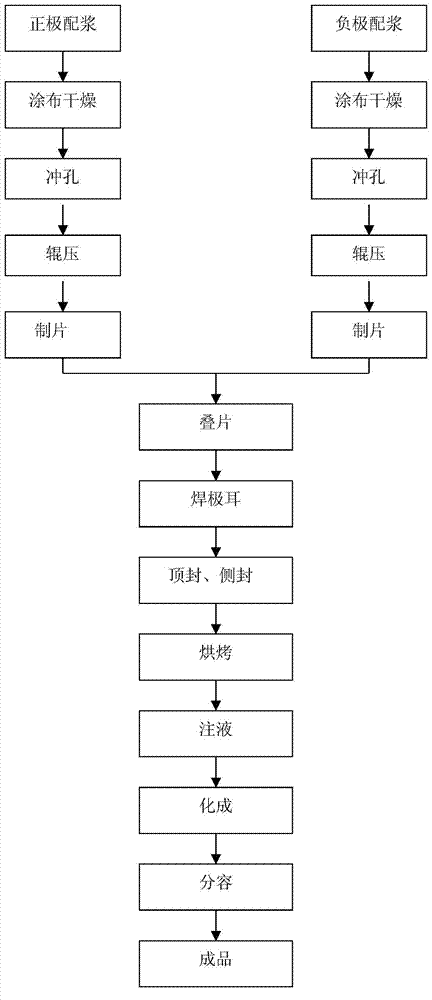

[0063] see figure 2 , the present invention simultaneously provides a kind of preparation method of above-mentioned high-power lithium-ion secondary battery, and it comprises the following steps:

[0064] m. Preparation of positive electrode green sheet: Mix the positive electrode active material, conductive agent, binder and solvent composed of two kinds of lithium cobaltate and lithium iron phosphate with different working voltages, mix them evenly, apply them on the aluminum foil, and dry them Form a positive electrode material layer on the surface of the aluminum foil;

[0065] n. Punching the positive electrode blank: punching a plurality of holes on the positive electrode blank, forming a plurality of positive electrode conduction holes on the aluminum foil, and forming positive electrode pores corresponding to the conduction holes on the positive electrode material layer;

[0066] o. Preparing the positive electrode sheet: rolling the punched positive electrode blank,...

Embodiment 1 04215-5

[0076] Embodiment one 104215-5Ah50C battery

[0077] Positive electrode binder preparation: Measure and weigh 3 parts of PVDF and 80 parts of nitrogen methylpyrrolidone NMP solvent, and fully stir until PVDF is completely dissolved.

[0078] Preparation of positive electrode slurry: Weigh 85 parts of lithium cobaltate, 9 parts of lithium iron phosphate, 2 parts of nano-carbon powder, and 1 part of conductive graphite, add the prepared positive electrode binder solution, and stir evenly.

[0079] Negative electrode binder preparation: Measure and weigh 1.6 parts of CMC and 100 parts of pure water, stir well until CMC is completely dissolved, then add 2.4 parts of SBR, stir until uniformly dispersed.

[0080] Negative electrode slurry preparation: weigh 94.5 parts of carbon material, 1.5 parts of nano-carbon powder, add the prepared negative electrode binder, and stir evenly.

[0081] Positive electrode coating surface density 200g / m 2 , the surface density of negative electro...

Embodiment 2

[0084] Example 2: 853496-2200mAh50C battery

[0085] Positive electrode binder preparation: Measure and weigh 3 parts of PVDF and 80 parts of nitrogen methylpyrrolidone NMP solvent, and fully stir until PVDF is completely dissolved.

[0086] Preparation of positive electrode slurry: Weigh 80 parts of lithium cobaltate, 13 parts of lithium iron phosphate, 2 parts of nano-carbon powder, and 2 parts of conductive graphite, add the prepared positive electrode binder solution, and stir evenly.

[0087] Negative electrode binder preparation: Measure and weigh 1.6 parts of CMC and 100 parts of pure water, stir well until CMC is completely dissolved, then add 2.4 parts of SBR, stir until uniformly dispersed.

[0088] Negative electrode slurry preparation: weigh 94.5 parts of carbon material, 1.5 parts of nano-carbon powder, add the prepared negative electrode binder, and stir evenly.

[0089] Positive electrode coating surface density 200g / m 2 , the surface density of negative elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com