Glass fiber baffle plate and lithium ion battery adopting glass fiber buffer plate

A technology for glass fiber separators and lithium-ion batteries, which can be used in secondary batteries, battery pack components, circuits, etc. Outstanding effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

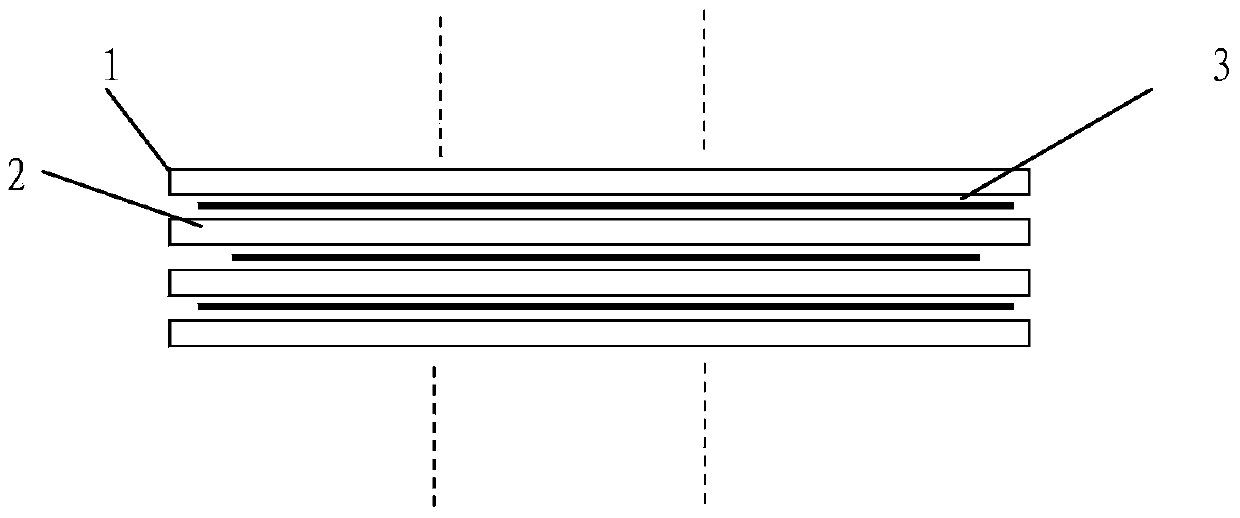

Image

Examples

Embodiment 1

[0024] The glass fiber separator of this embodiment includes 90kg of glass fibers and 10kg of bonding glue. Wherein, the diameter of the glass fiber is 1-2 μm, and the bonding glue is silane glue.

[0025] Pour 90kg of glass fiber and 120kg of deionized water into the mixing tank, stir at a speed of 60 rpm for 3 hours, remove slag after three sedimentation, pull pulp at a speed of 5 m / min, and pass through shaping rollers Roll forming to remove water, soak glue at a speed of 1 liter / min, dry in an oven at 95°C over 15 meters, and wind up. The thickness of the formed glass fiber separator is 270 μm.

Embodiment 2

[0027] The fiberglass separator of this embodiment includes 95kg of glass fibers and 5kg of bonding glue. Wherein, the diameter of the glass fiber is 0.5-1 μm, and the bonding glue is polyvinylidene fluoride glue.

[0028] Pour 95kg of glass fiber and 130kg of deionized water into the mixing tank, stir at a speed of 60 rpm for 3 hours, remove slag through three sedimentation, pull pulp at a speed of 4 m / min, and pass through the shaping roller Roll forming to remove water, soak glue at a speed of 0.8 liters / minute, pass through a 15-meter 90°C oven to dry, and wind up. The thickness of the formed glass fiber separator is 300 μm.

Embodiment 3

[0030] The glass fiber separator of this embodiment includes 80kg of glass fibers and 20kg of bonding glue. Wherein, the diameter of the glass fiber is 8-10 μm, and the bonding glue is acrylic glue and styrene-butadiene rubber, and the mass ratio of the two is 1:1.

[0031] Pour 80kg of glass fiber and 100kg of deionized water into the mixing tank, stir at a speed of 60 rpm for 4 hours, remove slag through three sedimentation, pull pulp at a speed of 6 m / min, and pass through the shaping roller Roll forming to remove water, soak glue at a speed of 1.2 liters / minute, pass through 15 meters of 100°C oven to dry, and wind up. The thickness of the formed glass fiber separator is 230 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com