Cleaning treatment method for n-type crystalline silicon substrate of solar cell

A technology of a solar cell and a processing method, applied in the field of device manufacturing, can solve the problems of low open-circuit voltage and short-circuit current of devices, high surface recombination rate of carriers, and poor surface passivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

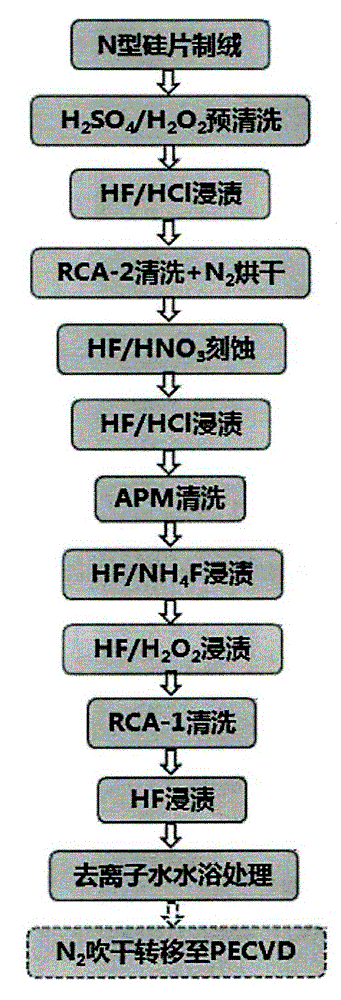

[0026] Such as figure 1 Shown, the cleaning processing method of the N-type crystalline silicon substrate of a kind of solar cell, the steps of this method are as follows:

[0027] (1) N-type silicon wafer texturing + H 2 SO 4 / H 2 o 2 Pre-cleaning: Rinse the N-type crystalline silicon substrate after texturing with deionized water, and then immerse it in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 5-15 minutes, and keep the temperature at 80-100°C. Rinse the substrate with deionized water for approximately 2.5 minutes; the ratio of concentrated sulfuric acid to hydrogen peroxide is 1:1 to 1:4;

[0028] (2) HF / HCL impregnation: then soak the substrate in a mixed solution containing 2% hydrochloric acid and 3% hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com