Method for preparing quasi-SOI (silicon on insulator) source drain multi-gate device

A source-drain and device technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as high thermal budget

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

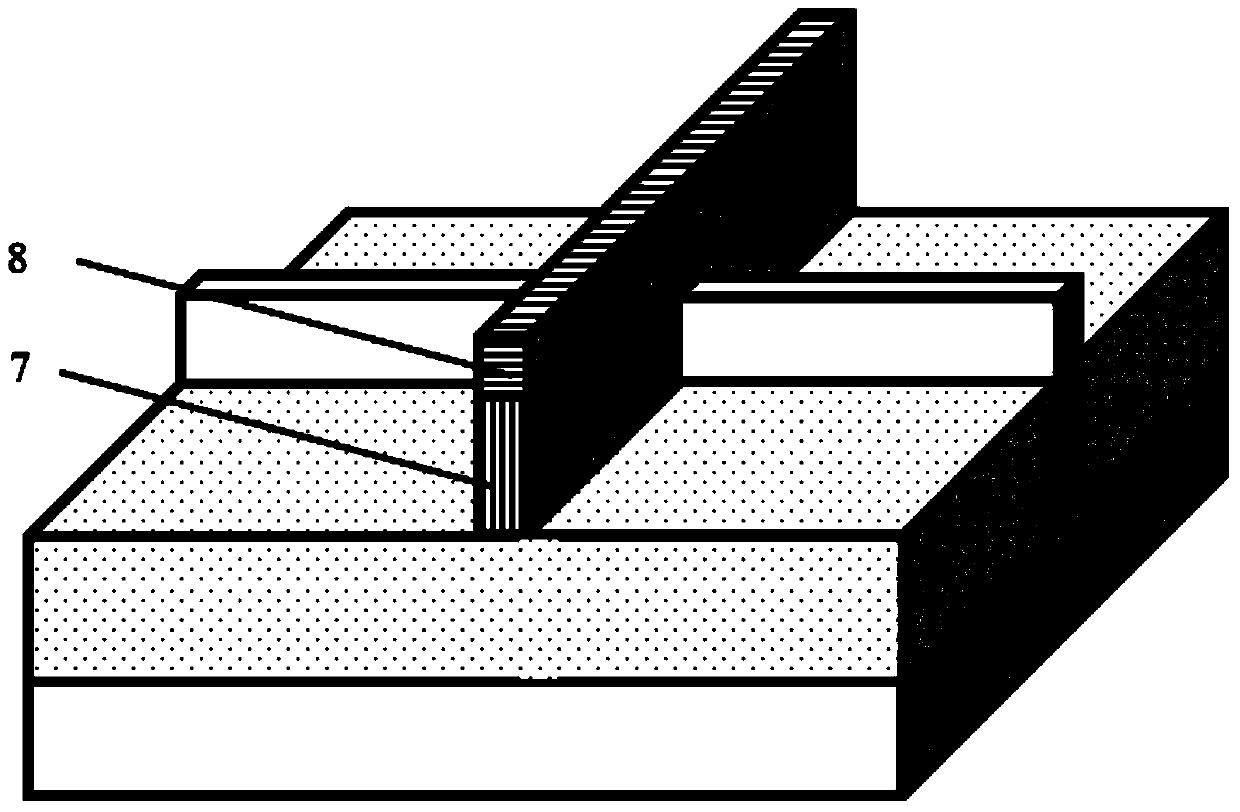

[0095] In the following, the present invention will be described in detail through specific embodiments in conjunction with the accompanying drawings, and a process scheme for preparing a quasi-SOI source-drain multi-gate device proposed by the present invention will be specifically given, but the scope of the present invention will not be limited in any way.

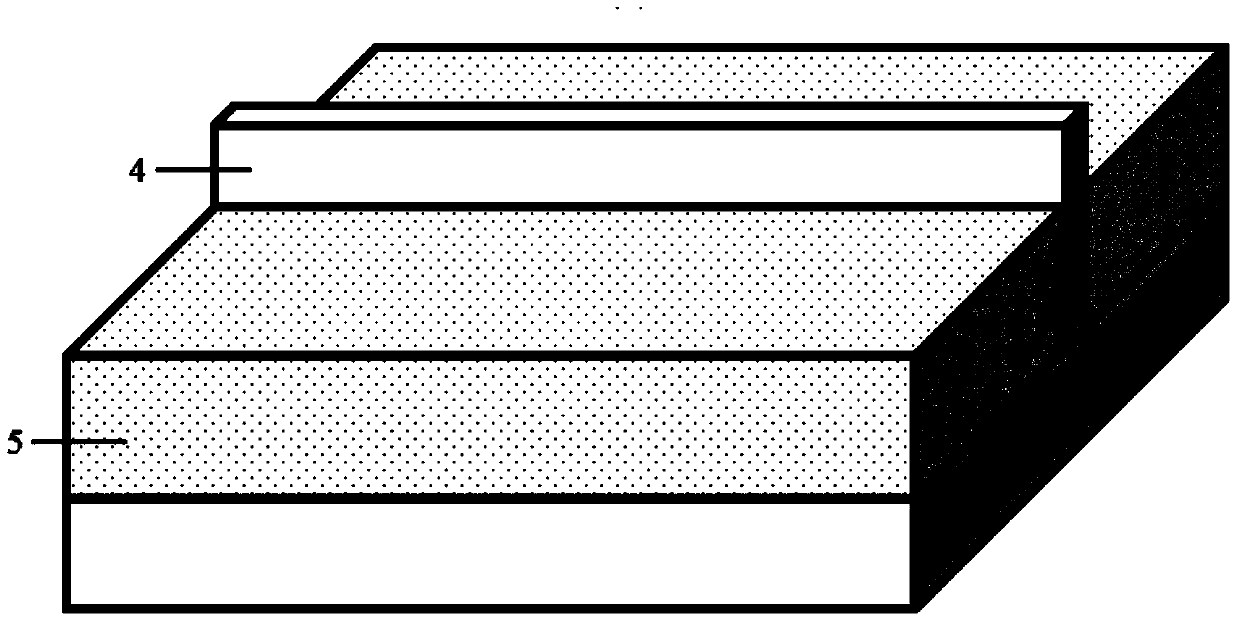

[0096] The specific implementation steps of preparing a quasi-SOI source-drain multi-gate device on a silicon substrate through a gate-last process are as follows:

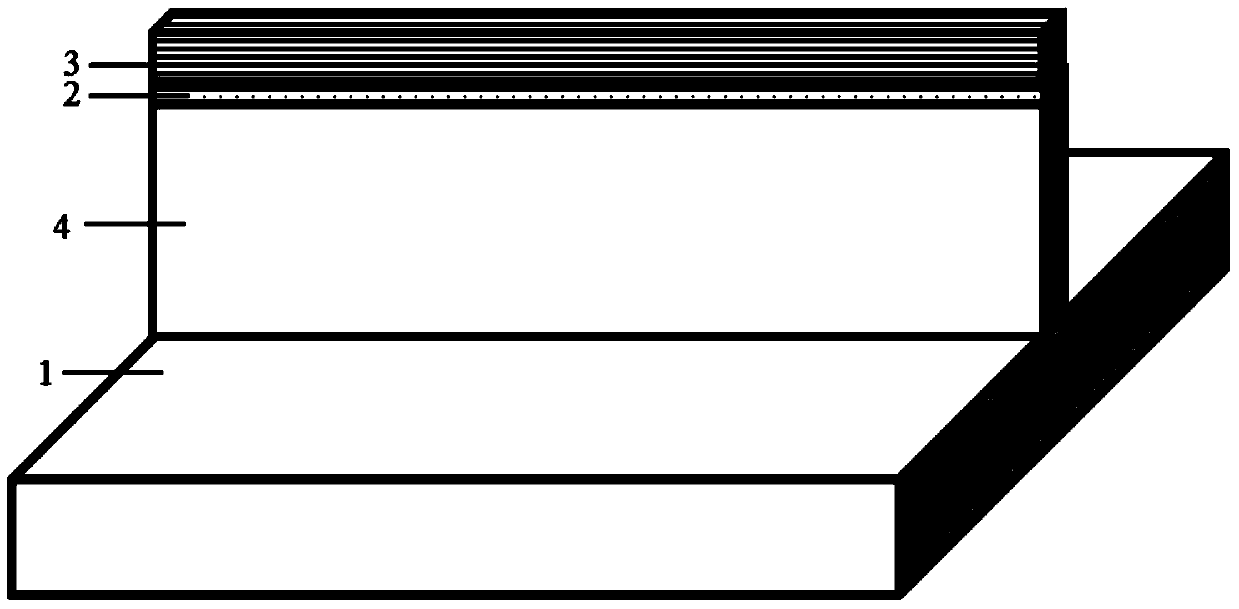

[0097] 1. Formed on a silicon substrate 1 by thermal oxidation The first layer of silicon oxide 2 serves as a buffer layer of silicon nitride.

[0098] 2. Deposition by LPCVD on the first layer of silicon oxide The first layer of silicon nitride 3 serves as a CMP stop layer.

[0099] 3. Photolithography and anisotropic dry etching The first layer of SiN3 and The first layer of silicon oxide 2 forms a hard mask layer of silicon Fin strips.

[0100] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com