The preparation method of citral

A technology of citral and dehydrolinalool, applied in the preparation of organic compounds, chemical instruments and methods, preparation of carbon-based compounds, etc., can solve the problem that the reaction yield of citral is not ideal, and citral cannot take into account the catalyst recovery of lemon Aldehyde yield, complex steps and other problems, to achieve the effect of good solubility, improve yield, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0026] A preparation and purification method of citral, comprising the steps of:

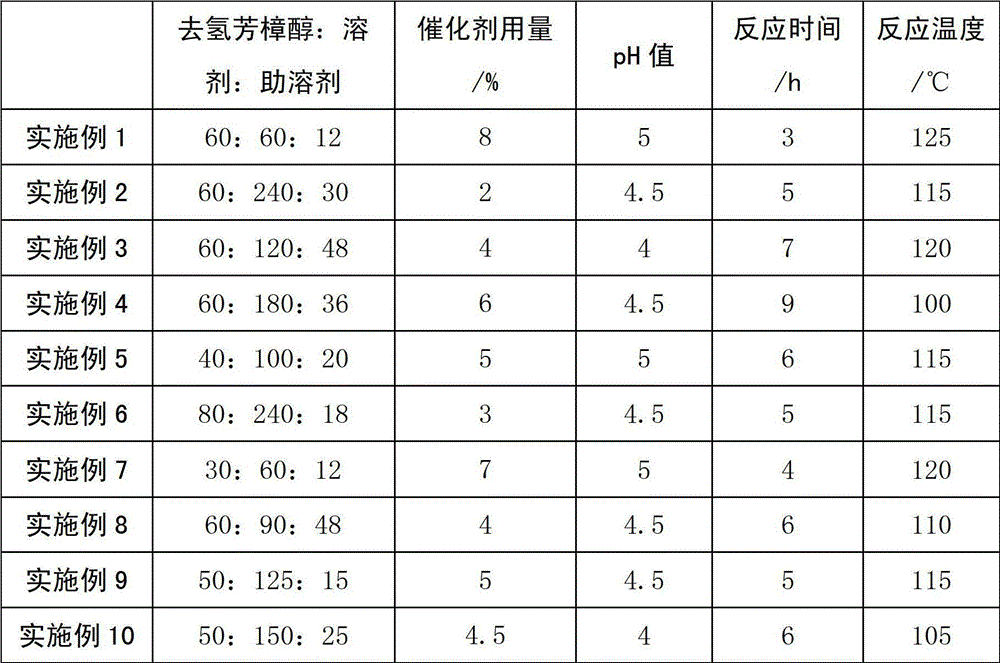

[0027] (1) In an oxygen-free environment at normal pressure, use ethylene glycol phenyl ether or diethylene glycol dibutyl ether as a solvent, alkyl sulfone as a co-solvent, use benzoic acid or phenylacetic acid to adjust the pH value, dehydrolinalool Catalytic rearrangement treatment is carried out under the action of molybdenum acetylacetonate catalyst. The reaction process conditions are shown in Table 1.

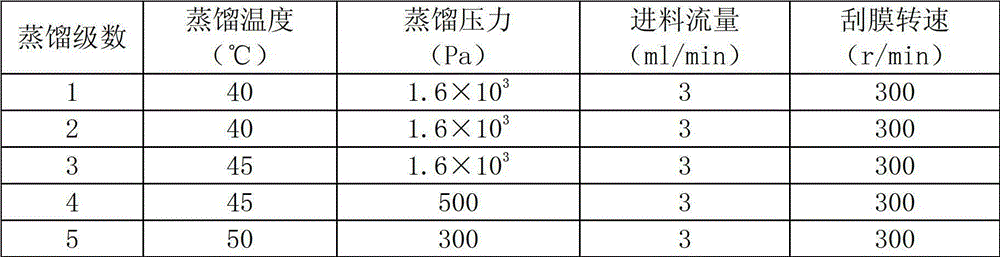

[0028] (2) The crude citral product obtained in step 1) is separated by five-stage molecular distillation. The process conditions of the five-stage distillation are shown in Table 2, and the refining results are shown in Table 3.

[0029] In the present embodiment, the pressure and temperature of each stage of the five-stage molecular distillation are set to be respectively:

[0030] The first stage: distillation pressure 1.6*10 3 Pa, distillation temperature 40°C;

[0031] The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com