Method for preparing three-dimensional porous stent composite layer

A three-dimensional porous and composite layer technology, applied in medical science, prosthesis, etc., can solve the problems of cumbersome procedures and inability to effectively guarantee the penetration of pores, and achieve the effect of low production cost and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

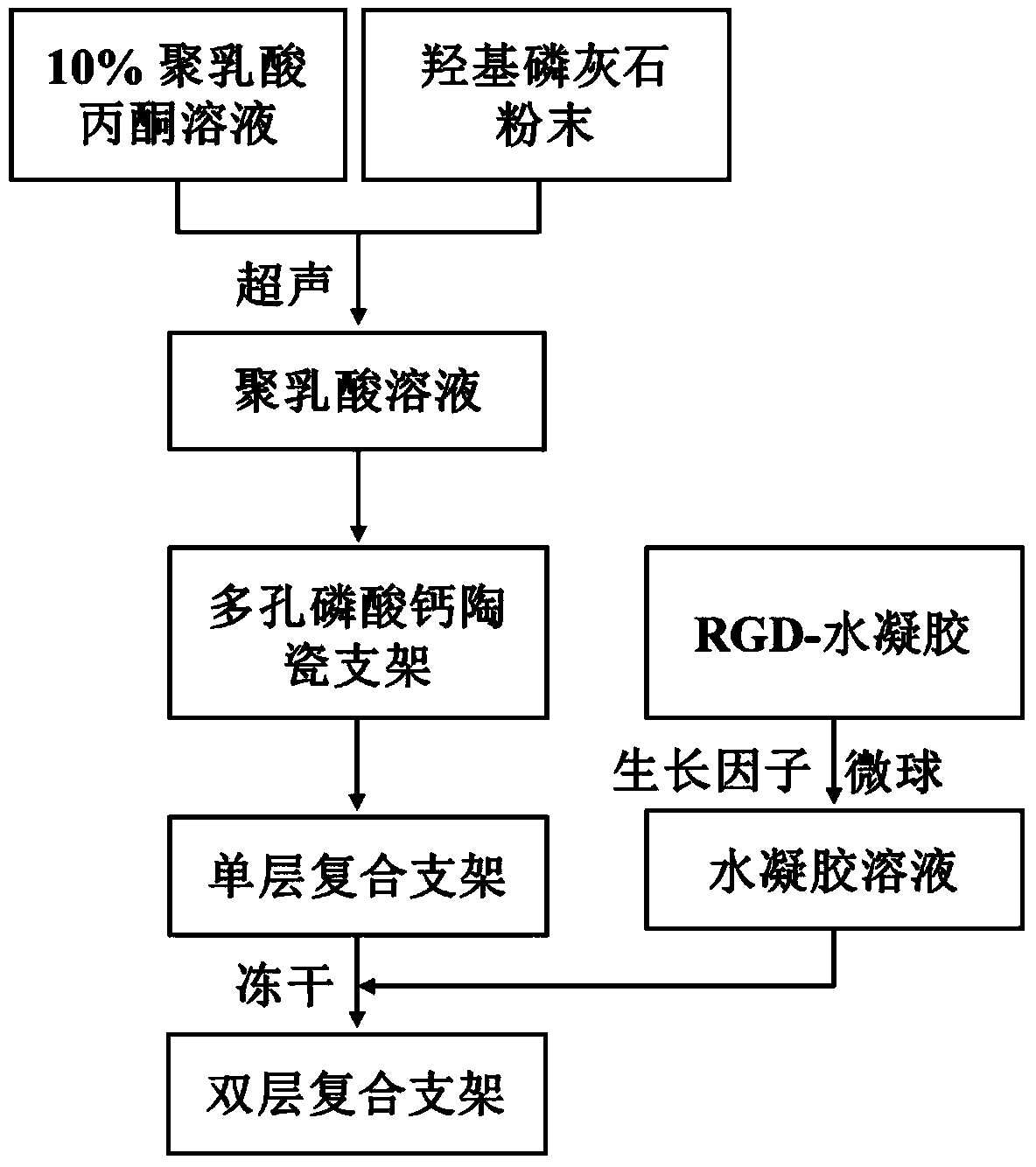

[0026] Example 1: Weigh 2.0 g of polylactic acid and dissolve it in 20 mL to prepare a solution with a mass volume ratio of 10%, then add 10% mass fraction of hydroxyapatite dry powder, and ultrasonically disperse and discard the underlying precipitate. The spare three-dimensional porous scaffold was placed in the solution, taken out after one minute and dried; the 10% arginine-glycine-aspartic acid sequence (RGD) graft was prepared with a pH=7.4 phosphate buffer solution. of oxidized sodium alginate solution and 2.5% N-succinyl chitosan solution. After sterilization, 9 mL of N-succinyl chitosan solution and 1 mL of RGD-grafted oxidized sodium alginate solution were mixed, and quickly stirred uniformly. The three-dimensional porous scaffold previously compounded with polylactic acid is put into the mixed solution, and after being quickly and uniformly coated, the excess hydrogel on the surface is removed; after freeze-drying, a three-dimensional porous scaffold compound layer ...

Embodiment 2

[0027] Example 2: Weigh 2.0g of polylactic acid and dissolve it in 20mL to prepare a solution with a mass-to-volume ratio of 10%, add 10% of hydroxyapatite dry powder by mass, and after ultrasonic dispersion, discard the underlying precipitate, and place the spare three-dimensional porous support into the solution. In this solution, take it out after one minute and spin dry; prepare 10% RGD-grafted oxidized sodium alginate solution and 2.5% N-succinyl chitosan solution with pH=7.4 phosphate buffer solution. After sterilization, 9 mL of N-succinyl chitosan solution and 1 mL of RGD grafted oxidized sodium alginate solution were mixed, and VEGF at a concentration of 10 ng / mL was added. 165 (vascular endothelial growth factor), BMP-2 (cell differentiation growth factor) at a concentration of 10ng / mL, and 10mg sodium alginate microspheres loaded with TGF-beat1 (transforming growth factor) and quickly stirred evenly. The three-dimensional porous scaffold is put into the mixed soluti...

Embodiment 3

[0028] Example 3: Weigh 2.0 g of polylactic acid and dissolve it in 20 mL to prepare a solution with a mass-to-volume ratio of 10%, add hydroxyapatite dry powder with a mass fraction of 10%, discard the bottom precipitate after ultrasonic dispersion, and place the porous scaffold in the dispersion. After one minute, take out and spin dry; prepare 10% RGD-grafted oxidized sodium alginate solution and 2.5% N-succinyl chitosan solution with pH=7.4 phosphate buffer solution, sterilize Then, 8 mL of N-succinyl chitosan solution was mixed with 2 mL of RGD grafted oxidized sodium alginate solution, and VEGF at a concentration of 10 ng / mL was added. 165 , 10ng / mL concentration of BMP-2 and 10mg were loaded into TGF-beat1 sodium alginate microspheres and quickly stirred uniformly. The three-dimensional porous scaffold previously compounded with polylactic acid was put into the mixed solution, and after rapid coating uniformly, the surface was removed. Excess hydrogel; freeze-drying to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com