PTC (Positive Temperature Coefficient) heating sheet, low-temperature radiating electrothermal film and preparation method of low-temperature radiating electrothermal film

A technology of low temperature radiation and heating sheet, applied in electric heating devices, electrical components, ohmic resistance electrodes, etc., can solve the problems of difficult to control printing quality, shortened product life, high cost, reduce process complexity, realize continuous production, The effect of enhancing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] see figure 1 ,2 , a method for preparing a low-temperature radiation electrothermal film of the present invention, comprising the steps of:

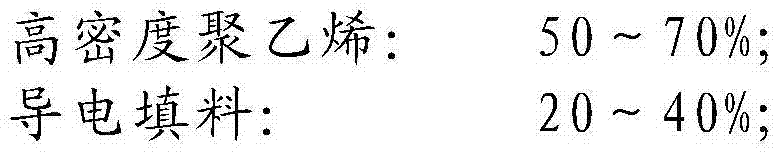

[0056] S1: Weigh each component according to the mass percentage ratio of 50-70% of high-density polyethylene, 20-40% of conductive filler, 5-10% of inorganic filler and 0.1-0.5% of coupling agent, and then grind the high-density polyethylene To form a powder, each component is sheared and blended by a high-speed mixer twin-screw for 10 minutes to obtain a mixed material; wherein, the conductive filler is carbon black; the inorganic filler is magnesium hydroxide.

[0057] S2: Extruding the mixed material through a single-screw T-shaped die at a temperature of 150-220°C to obtain the extruded material;

[0058] S3: pressing the extruded material to a fixed thickness through a calender at a temperature of 150° C. and flattening both edges to obtain a sheet with a thickness of 0.20 mm and a width of 0.5 m;

[0059] S4: Press the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com