Non-aqueous electrolyte and application thereof

A non-aqueous electrolyte and additive technology, which is applied in the field of materials, can solve the problems of rapid cycle performance attenuation, and achieve the effect of improving high temperature and normal temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] in an argon-filled glove box (H 2 O6 ) in which, 2% by mass of vinyl vinyl sulfate was added to the electrolyte.

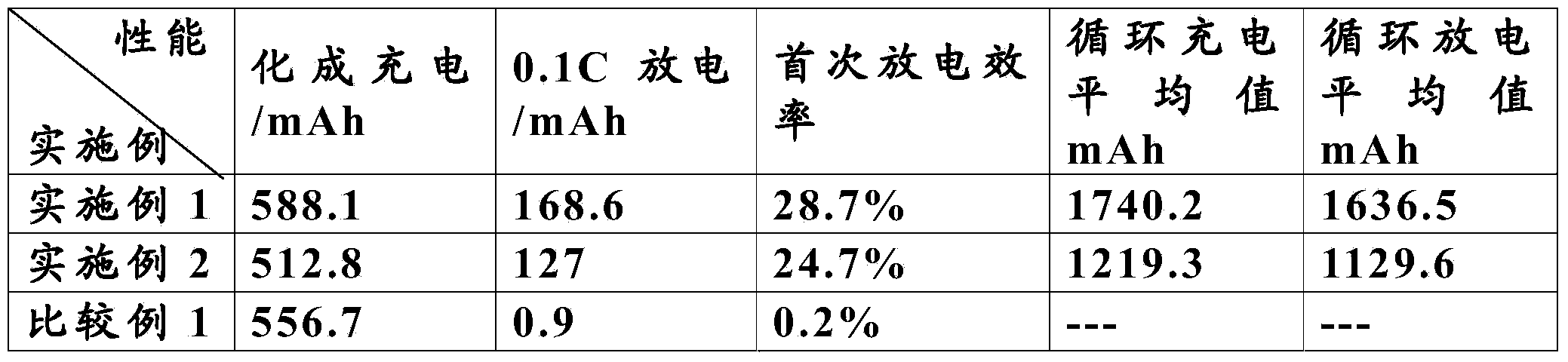

[0025] Inject the electrolyte into a 1.5A lithium iron phosphate soft pack battery, charge and discharge the battery at 0.1C to form the battery, measure its first charge and discharge efficiency, and then test its average charge and discharge capacity at 0.2C charge and discharge cycle for 10 weeks. The results are shown in Table 1.

Embodiment 2

[0027] in an argon-filled glove box (H 2 O6 ) in which, 5% by mass of vinyl vinyl sulfate was added to the electrolyte.

[0028] The above electrolytic solution was formed under the same conditions as in Example 1, and then its average charge-discharge capacity was tested under the same conditions as in Example 1. The results are shown in Table 1.

Embodiment 3

[0035] in an argon-filled glove box (H 2 O6 ) in which, 1% by mass of vinyl vinyl sulfate, 0.2% of triphenyl phosphite and 2% of cyclohexylbenzene were added to the electrolyte.

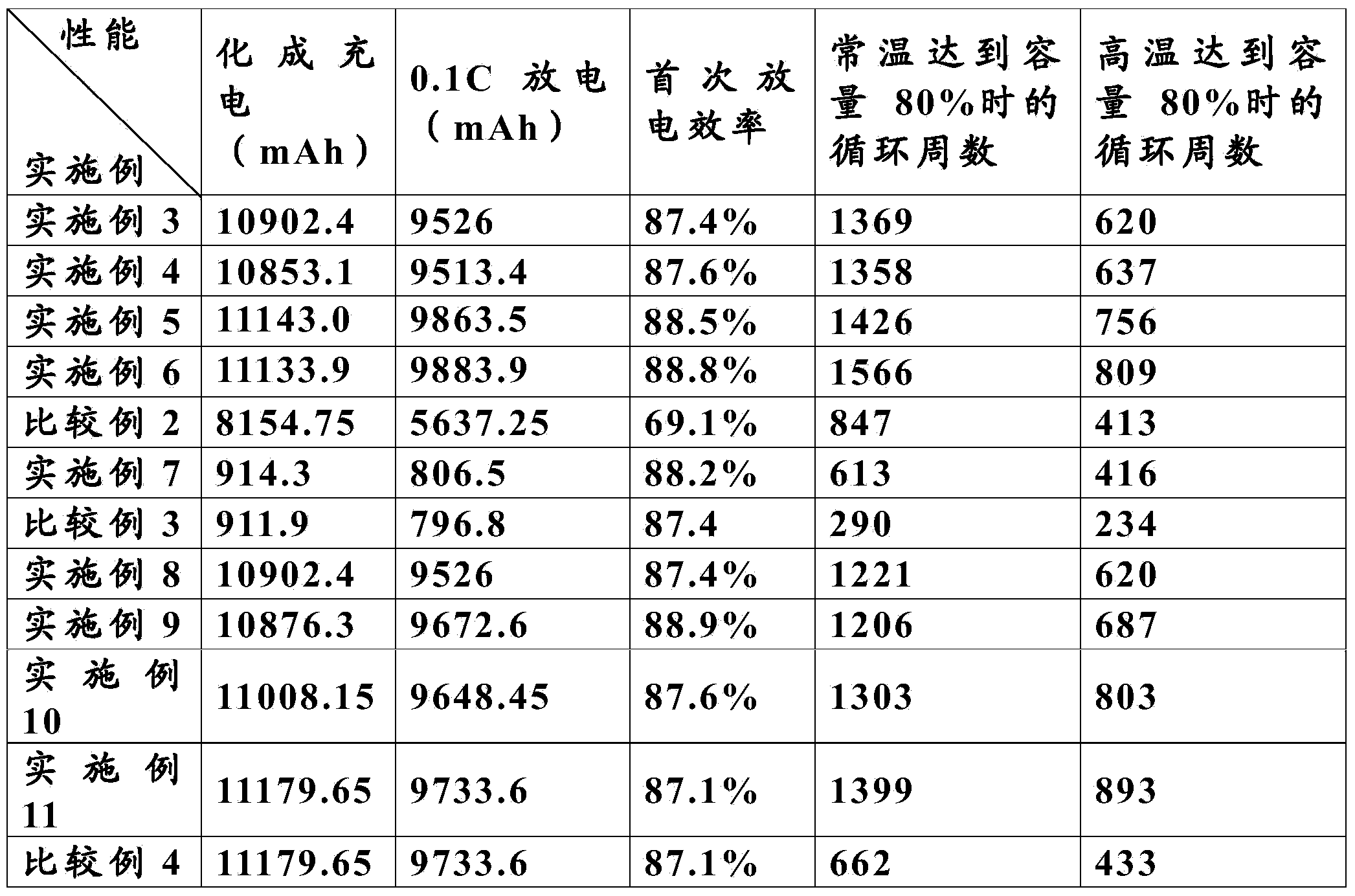

[0036] Inject the electrolyte solution into a 10A lithium iron phosphate aluminum shell battery, charge and discharge the battery at 0.1C to form the battery, measure its first charge and discharge efficiency, and then conduct a 1C charge and discharge cycle at room temperature and high temperature at 45°C to test its cycle at room temperature and high temperature performance, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com