Non-cobalt IT-SOFC (Intermediate-Temperature Solid Oxide Fuel Cell) stable anode material and application thereof

A solid oxide and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor structural stability and chemical stability at high temperature, performance degradation, and large thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

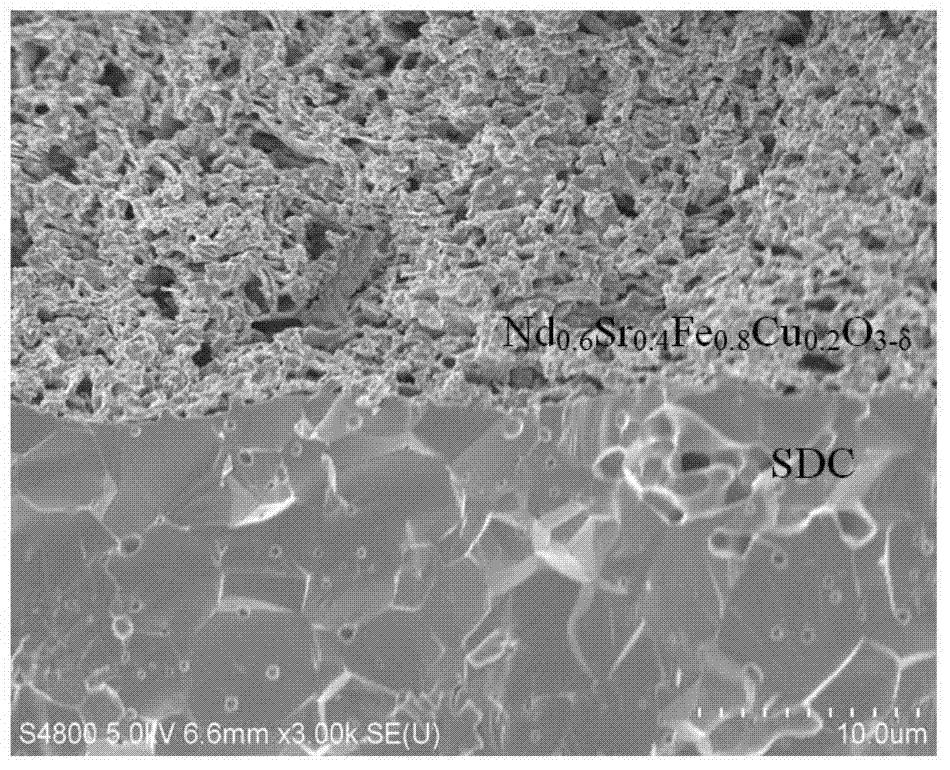

[0034] 0.1mol Nd x Sr 1-x Fe 0.8 Cu 0.2 o 3-δ (0.3≤x≤0.7) synthesis, structure test and cathode performance test.

[0035] First, 58.4484g of EDTA was dissolved in 100mL of ammonia water, and then Nd(NO 3 ) 3 ·6H 2 O powder (13.152-30.688g), Sr(NO 3 ) 2 Powder 10.5815g, Fe(NO 3 ) 3 9H 2 O powder 32.32g and Cu(NO 3 ) 2 ·3H 2 O powder 4.832g, be dissolved in the prepared EDTA solution, then add the citric acid of 57.6370g, the mol ratio of EDTA, citric acid and total metal ion is 1:1.5:1, then add ammonia water to adjust the solution The pH value is 6-10, heated to 50-100°C to form a uniform and transparent sol, and the heating time is further extended until the water evaporates to obtain a viscous gel, which is heat-treated at 200-400°C to obtain a fluffy precursor , the precursor can be calcined at 900-1200°C to obtain the required Nd 0.5 Sr 0.5 Fe 0.8 Cu 0.2 o 3-δ Powder.

[0036] Such as figure 1 shown, for Nd x Sr 1-x Fe 0.8 Cu 0.2 o 3-δ (0.3≤x≤0....

Embodiment 2

[0042] 0.05mol of Nd 0.3 Sr 0.7 Fe 0.8 Cu 0.2 o 3-δ synthesis and structural testing.

[0043] The EDTA of 29.2242g is dissolved in 80mL ammoniacal liquor, then the Nd(NO 3 ) 3 ·6H 2 O powder 6.576g, Sr(NO 3 ) 2 Powder 7.408g, Fe(NO 3 ) 3 9H 2 O powder 16.16g and Cu(NO 3 ) 2 ·3H 2O powder 2.416g, be dissolved in the prepared EDTA solution, then add the citric acid of 28.8185g, the mol ratio of EDTA, citric acid and total metal ion is 1:1.5:1, then add ammonia water to adjust the solution The pH value is 7, heated to 80°C to form a uniform and transparent sol, and the heating time is further extended until the water evaporates to obtain a viscous gel, which is heat-treated at 250°C to obtain a fluffy powder precursor. The body can be calcined at 1000°C to obtain the required Nd 0.3 Sr 0.7 Fe 0.8 Cu 0.2 o 3-δ Powder. Figure 5 for Nd 0.3 Sr 0.7 Fe 0.8 Cu 0.2 o 3-δ The XRD pattern of it shows that it is a perovskite structure.

Embodiment 3

[0045] 0.05mol of Nd 0.7 Sr 0.3 Fe 0.8 Cu 0.2 o 3-δ Synthesis, structure testing.

[0046] The EDTA of 29.2242g is dissolved in 80mL ammoniacal liquor, then the Nd(NO 3 ) 3 ·6H 2 O powder 15.344g, Sr(NO 3 ) 2 Powder 3.175g, Fe(NO 3 ) 3 9H 2 O powder 16.16g and Cu(NO 3 ) 2 ·3H 2 O powder 2.416g, be dissolved in the prepared EDTA solution, then add the citric acid of 28.8185g, the mol ratio of EDTA, citric acid and total metal ion is 1:1.5:1, then add ammonia water to adjust the solution The pH value is 8, heated to 80°C to form a uniform and transparent sol, and the heating time is further extended until the water evaporates to obtain a viscous gel, which is heat-treated at 250°C to obtain a fluffy powder precursor. The body can be calcined at 1000°C to obtain the required Nd 0.7 Sr 0.3 Fe 0.8 Cu 0.2 o 3-δ Powder. Figure 6 for Nd 0.7 Sr 0.3 Fe 0.8 Cu 0.2 o 3-δ The XRD pattern of it shows that it is a perovskite structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com