Insulated wire and coil using the same

A technology for insulating wires and insulating layers, applied in insulated cables, insulated conductors, organic insulators, etc., can solve problems such as reduced mechanical strength, and achieve the effects of excellent processability, high storage modulus, and excellent processability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] Hereinafter, embodiments of the insulated electric wire and the coil using the insulated electric wire according to the present invention will be specifically described.

[0031] (insulated wire)

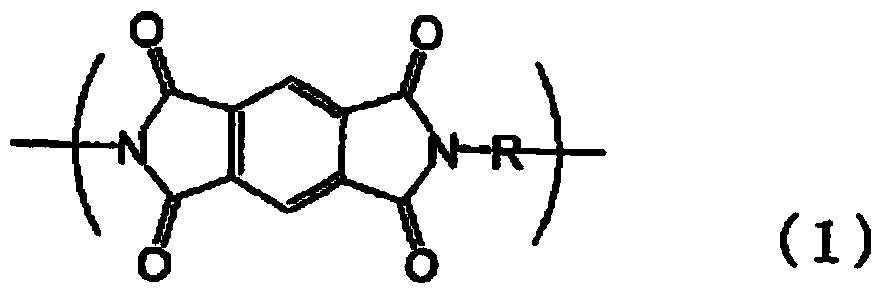

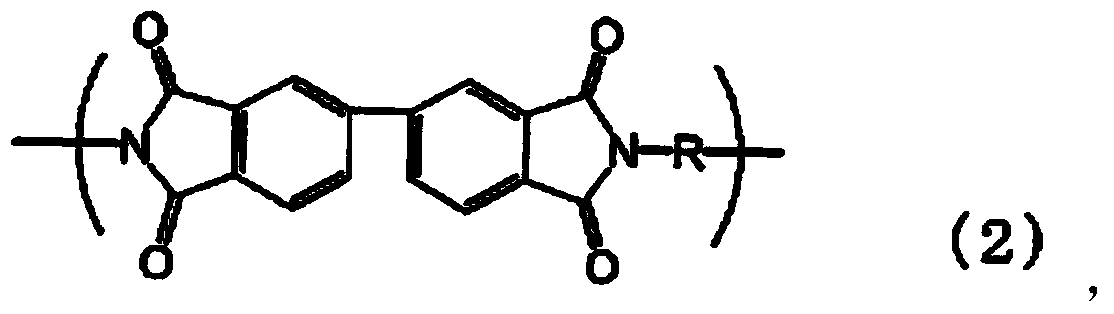

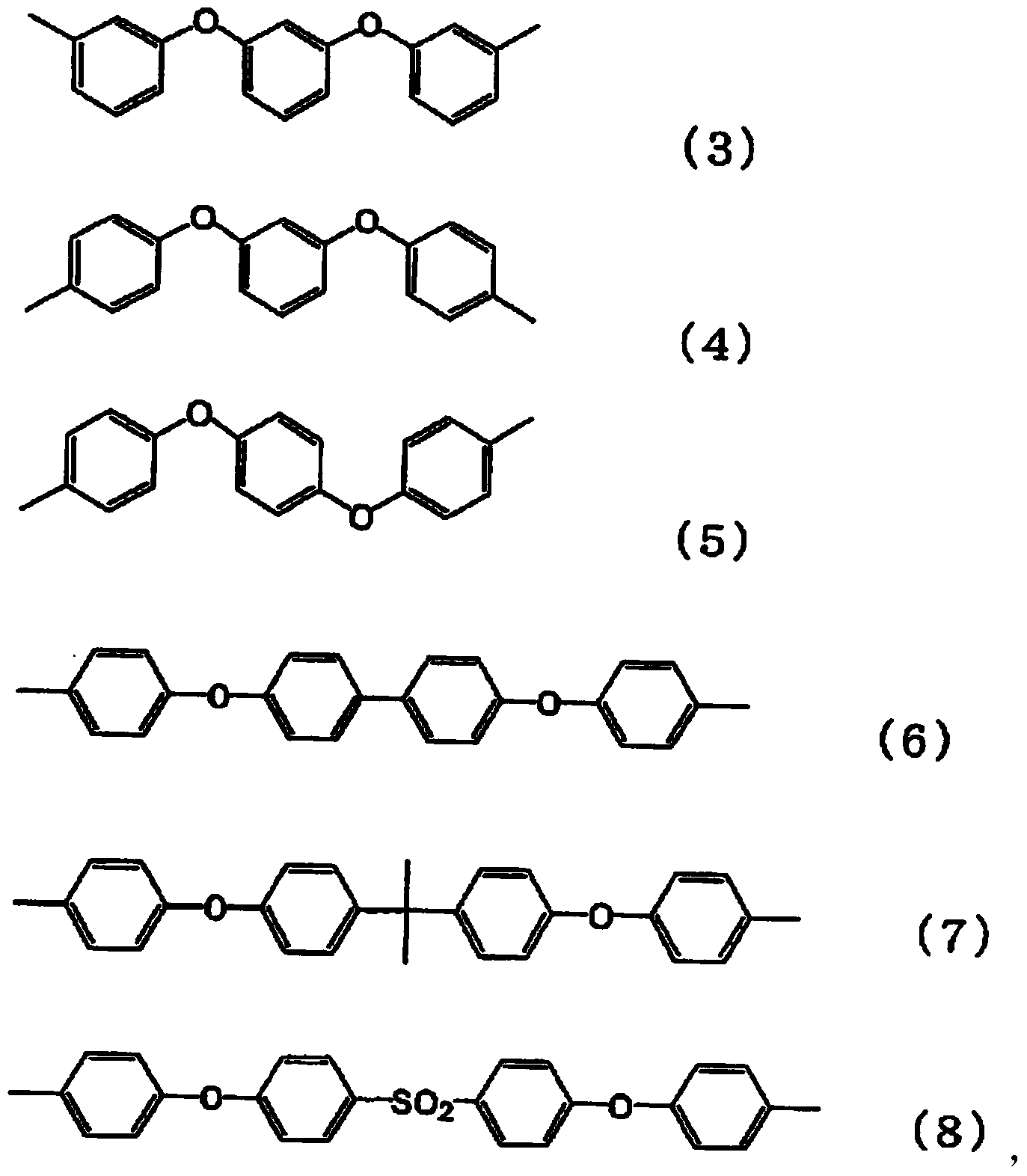

[0032] The insulated electric wire of this embodiment includes: a conductor; and an insulating layer made of polyimide provided on the outer periphery of the conductor, the insulating layer is composed of a repeating unit represented by the above formula (1) and a compound represented by the above formula (2). The polyimide composition of the repeating unit is composed of the first acid component in the repeating unit represented by the above formula (1) and the second acid component in the repeating unit represented by the above formula (2), in a molar ratio (the first In the case of acid component: second acid component), it is compounded in a molar ratio range of 85:15 to 40:60, and the residue R of the diamine component in the above formula (1) and the above formula (2) i...

Embodiment 1)

[0058] After dissolving 4,4'-diaminodiphenyl ether (ODA) and 4,4'-bis(4-aminophenoxy)biphenyl (BAPB) in N-methylpyrrolidone (NMP), dissolve it in Pyromellitic dianhydride (PMDA) and 3,3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA) were stirred at room temperature for 12 hours to obtain "PMDA:s-BPDA:ODA:BAPB =75:25:85:15”mixing ratio of polyamic acid paint. This polyamic acid paint was diluted and adjusted for painting workability. The following process was repeated 15 times to obtain an insulated wire with a film thickness of 40 μm: Coating the obtained coating on a copper wire with a diameter of 0.8 mm by a normal method, and firing in a coating furnace at 450° C. for 90 seconds.

Embodiment 2)

[0060] In Example 1, it carried out similarly to Example 1 except having changed the compounding ratio of the polyamic-acid paint into "PMDA:s-BP DA:ODA:BAPB=50:50:50:50".

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com