Preparation method of magnesium alloy surface micro-arc oxidized nano self-assembling composite protective coating

A nano-self-assembly and micro-arc oxidation technology, which is applied to the surface coating liquid device, coating, anodic oxidation, etc., to achieve stable performance, wide range of sources, and the effect of inhibiting polymerization reaction

- Summary

- Abstract

- Description

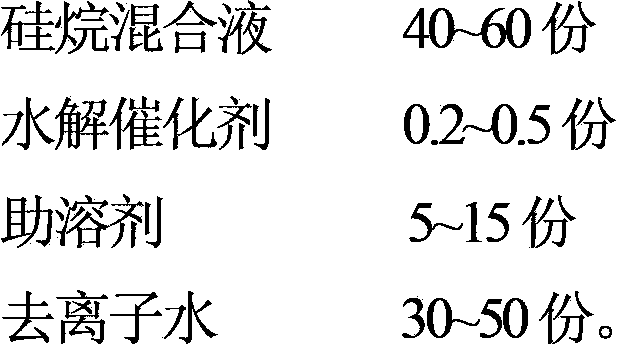

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

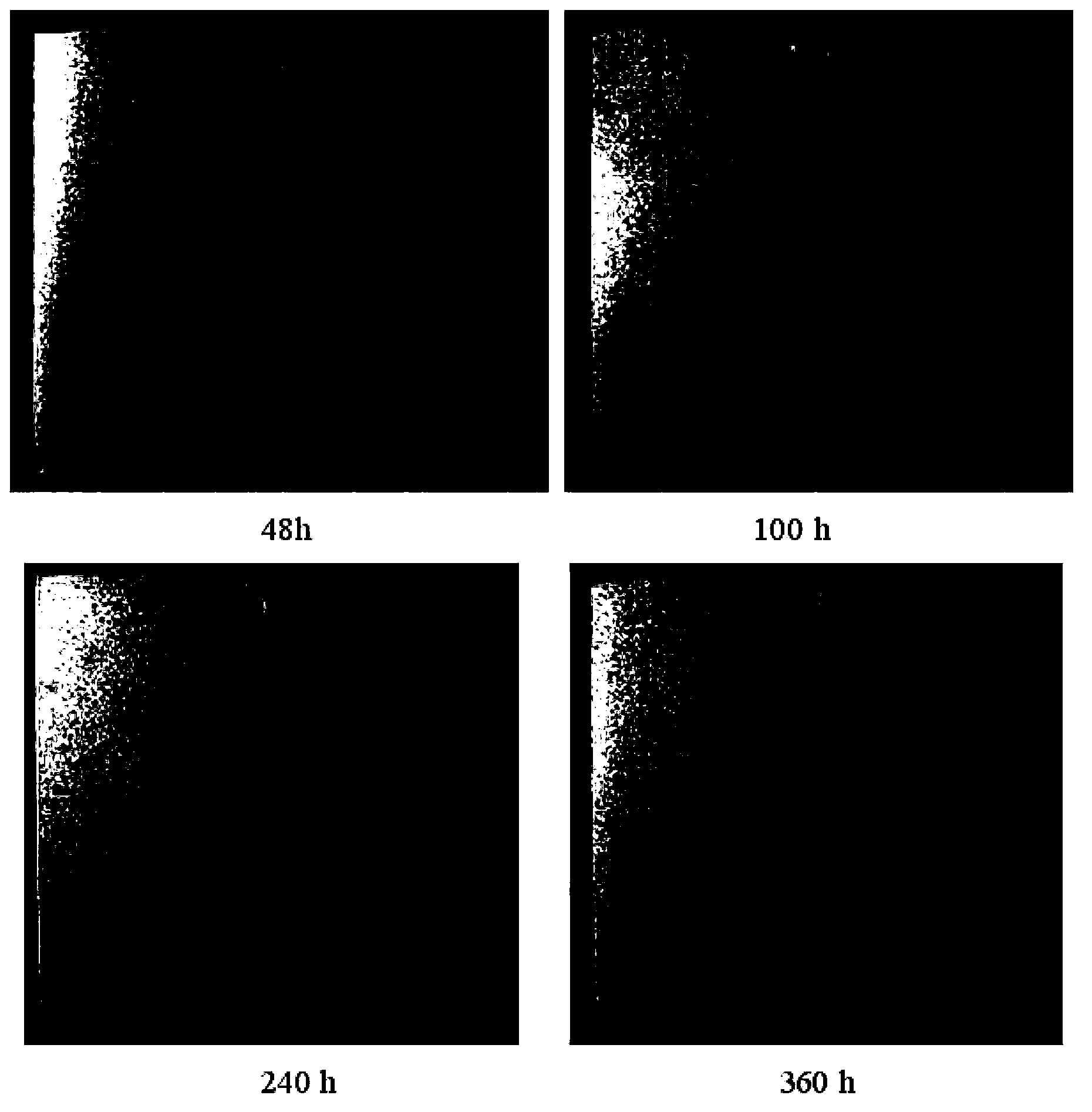

Examples

Embodiment 1

[0031] 1. Material preparation: After the AZ91D magnesium alloy is cut, polished and polished, it is cleaned and degreased by ultrasonic waves in absolute ethanol solution.

[0032] 2. The configuration of micro-arc oxidation: sodium hydroxide 2g / L, sodium silicate 5g / L, the rest is water, and the temperature is room temperature. Micro-arc oxidation is carried out by high-voltage pulse method, the pulse frequency is 200Hz, and the current density is 2A / dm 2 , the oxidation time is 30min, the oxide film thickness is 10μm, the porosity is 30%, and the pore size is 1-4μm.

[0033] 3. Preparation of modified composite coating:

[0034] 1) Configuration of silane mixture. Mix and stir the silane KH-560 and TEOS at a molar ratio of n(KH560):n(TEOS)=4:1 to obtain a silane mixture.

[0035] 2) The configuration of the hydrolysis catalyst. Acetic acid and phytic acid are uniformly mixed in a molar ratio of n(acetic acid):n(phytic acid)=3:1 to obtain a hydrolysis catalyst.

[0036]...

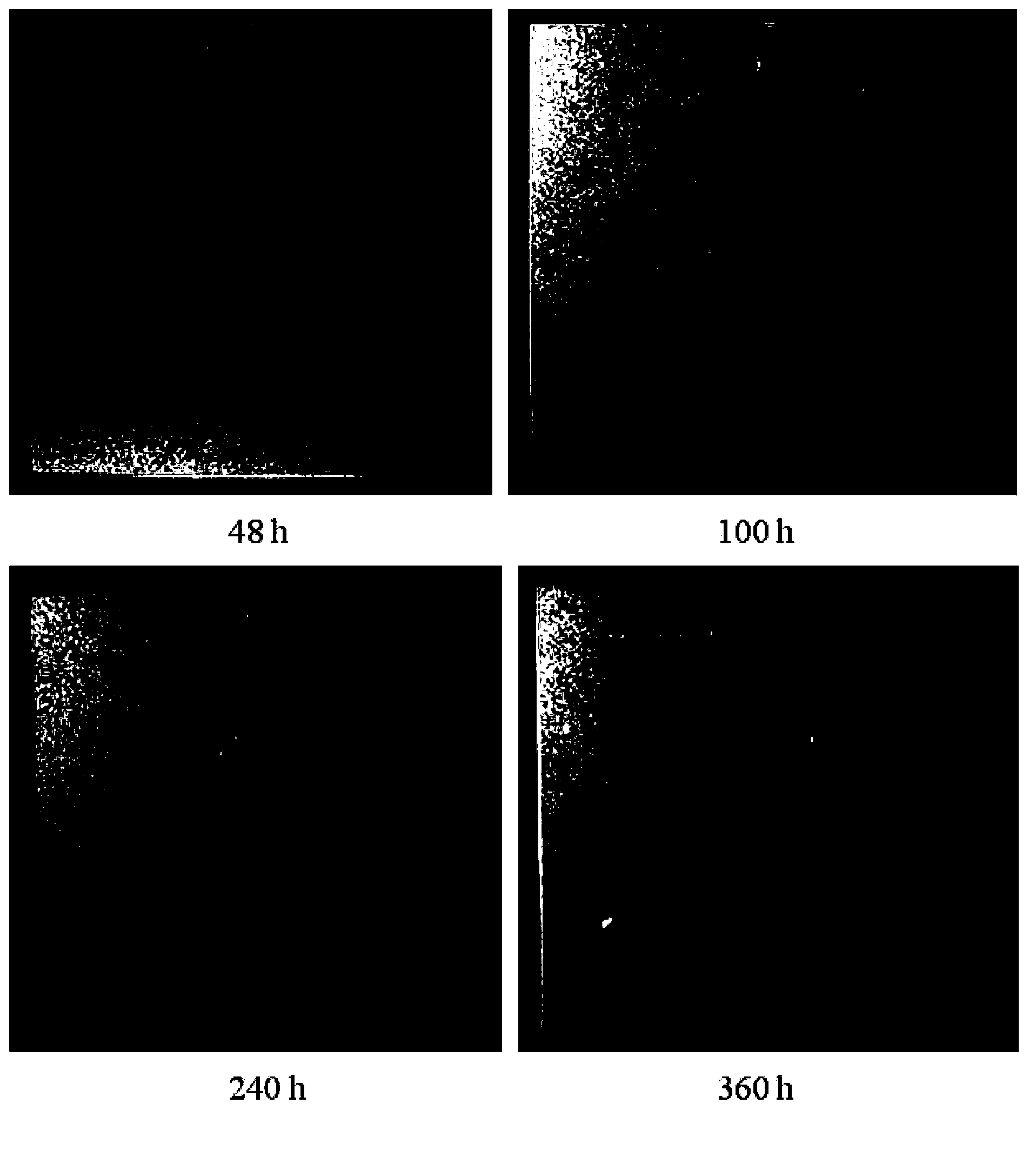

Embodiment 2

[0052] 1. Material preparation: After the AZ31B magnesium alloy is cut, polished and polished, it is cleaned and degreased by ultrasonic waves in absolute ethanol solution.

[0053] 2. The configuration of micro-arc oxidation: sodium hydroxide 5g / L, sodium silicate 5g / L, the rest is water, and the temperature is room temperature. Micro-arc oxidation is carried out by high-voltage pulse method, the pulse frequency is 350Hz, and the current density is 2A / dm 2 , the oxidation time is 40min, the oxide film thickness is 15μm, the porosity is 28%, and the pore size is 2~5μm.

[0054] 3. Preparation of modified composite coating:

[0055] 1) Configuration of silane mixture. Mix and stir silane KH-560 and TEOS at a molar ratio of n(KH560):n(TEOS)=5:1 to obtain a silane mixture.

[0056] 2) The configuration of the hydrolysis catalyst. Acetic acid and phytic acid are uniformly mixed in a molar ratio of n(acetic acid):n(phytic acid)=:2 to obtain a hydrolysis catalyst.

[0057] 3) C...

Embodiment 3

[0065] 1. Material preparation: After AZ31B magnesium alloy is cut, polished and polished, it is cleaned and degreased by ultrasonic wave in acetone solution.

[0066] 2. The configuration of micro-arc oxidation: sodium hydroxide 5g / L, sodium silicate 15g / L, the rest is water, and the temperature is room temperature. Micro-arc oxidation is carried out by high-voltage pulse method, the pulse frequency is 500Hz, and the current density is 3A / dm 2 , the oxidation time is 30min, the oxide film thickness is 14~15μm, the porosity is 35%, and the pore diameter is 2~5μm.

[0067] 3. Preparation of modified composite coating:

[0068] 1) Configuration of silane mixture. Mix and stir silane KH-560 and TEOS at a molar ratio of n(KH560):n(TEOS)=5:2 to obtain a silane mixture.

[0069] 2) The configuration of the hydrolysis catalyst. Acetic acid and phytic acid are uniformly mixed in a molar ratio of n(acetic acid):n(phytic acid)=4:1 to obtain a hydrolysis catalyst.

[0070] 3) Config...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com