Production method for smelting high carbon chromium iron by using carbonaceous combination reducing agent

A high-carbon ferrochrome and production method technology, applied in the field of smelting high-carbon ferrochrome, can solve problems such as difficult control of furnace conditions, threats to safe production, and easy fire on the material surface of the furnace mouth, so as to reduce raw material costs and consumption, The effect of improving the economic efficiency of the factory and reducing the cost of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

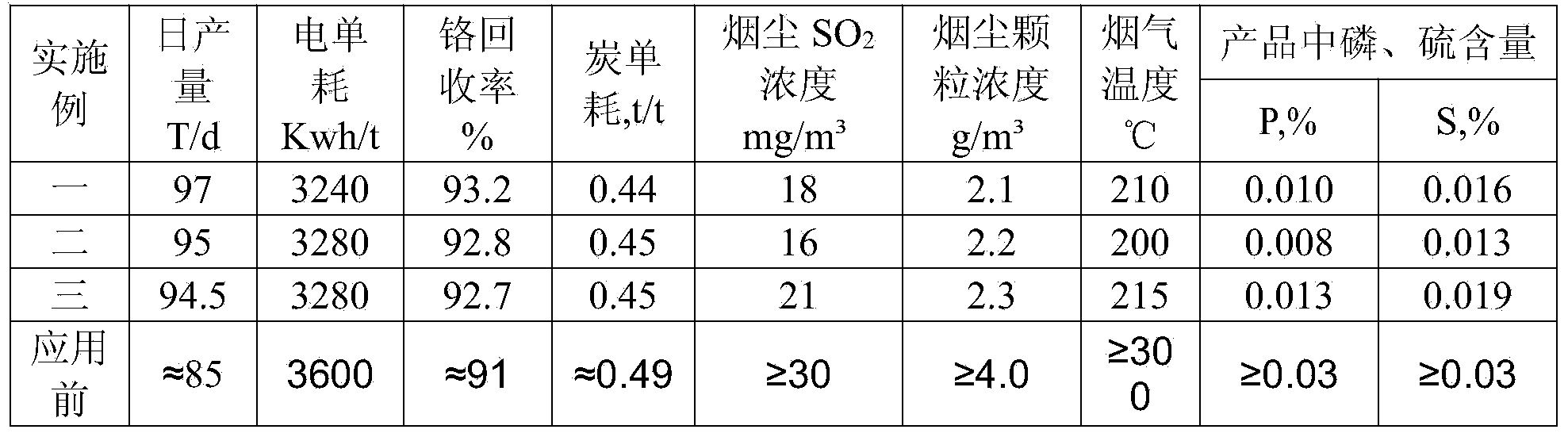

Embodiment 1

[0042]Applying the method of the present invention, the water content of the raw material reducing agent in the furnace is 2.7%, the particle size of the ore raw material: the particle size of the raw material is controlled at 20-100 mm, and the proportion of particle size ≦ 20 mm is below 8%, and the particle size of the carbonaceous reducing agent is 10-50 mm , Proportion of carbonaceous reducing agent: semi-coke 45%, metallurgical coke 30%, anthracite 25%, operation measures: batching link, each batch of material 300 (㎏ / batch), mixed material, mixed again through the mixing silo. For the control of the material surface, the thickness of the furnace mouth should be controlled within 130mm at one time. For the areas with poor air permeability on the material surface, timely measures should be taken to loosen the material surface and improve the air permeability. During the application period in production practice, the production and operation of the submerged arc furnace is i...

Embodiment 2

[0044] Applying the method of the invention, the water content of the raw material reducing agent in the furnace is 3.0, the particle size of the ore raw material: the particle size of the raw material is controlled at 10-100 mm, and the proportion of the particle size ≦ 10 mm is below 10%, and the particle size of the carbonaceous reducing agent is 10-50 mm. Proportion of carbonaceous reducing agent: semi-coke 55%, metallurgical coke 30%, anthracite 15%, operation measures: batching link, each batch of 400 (㎏ / batch), mixed material, mixed again through the mixing silo. For the control of the material surface, the thickness of the furnace mouth should be controlled within 150 mm at one time. For the areas with poor air permeability on the material surface, the eye-catching and loose material surface should be adopted to improve the air permeability. During the application period in production practice, the production and operation of the submerged arc furnace is in good conditi...

Embodiment 3

[0046] Applying the method of the invention, the water content of the raw material reducing agent in the furnace is 2.7%, the particle size of the ore raw material: the particle size of the raw material is controlled at 10-100 mm, and the proportion of the particle size ≦ 10 mm is at least 8%, and the particle size of the carbonaceous reducing agent: 10-50 mm , Proportion of carbonaceous reducing agent: semi-coke 25%, metallurgical coke 60%, anthracite 15%, operation measures: batching link, each batch of material 300 (㎏ / batch), mixed material, mixed again through the mixing silo. For the control of the material surface, the thickness of the furnace mouth should be controlled within 100mm at one time. For the areas with poor air permeability on the material surface, the eye-catching and loose material surface should be adopted to improve the air permeability. During the application period in production practice, the production and operation of the submerged arc furnace is in go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com