Full-automatic hot-air sludge drying equipment and drying method thereof

A sludge drying, fully automatic technology, applied in chemical instruments and methods, separation methods, dewatering/drying/concentrating sludge treatment, etc. materials, etc., to prevent waste of heat and ensure stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

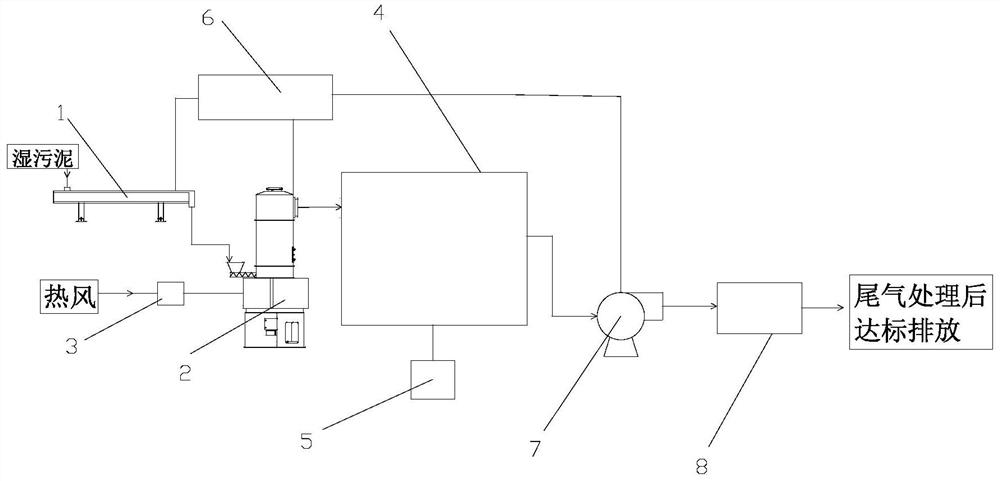

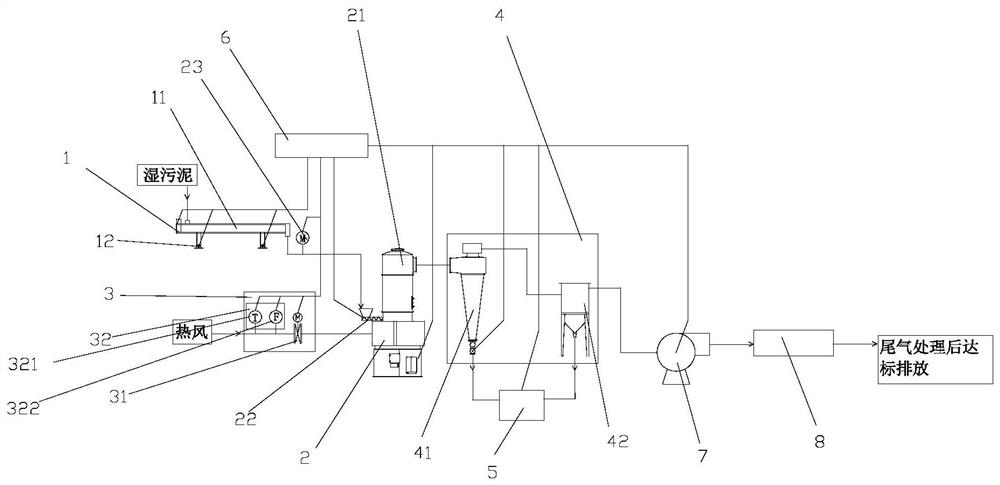

[0039] Such as figure 1 , figure 2 A fully automatic hot air sludge drying equipment is shown. The automatic hot air sludge drying equipment consists of a continuous weighing system 1, a sludge drying system 2 for drying wet sludge, and a control system for controlling the air intake of hot air. Automatic air distribution system 3, solid-gas separation system for separating dried sludge and waste gas 4, discharge system for collecting dried sludge 5, main control system for deploying various systems to cooperate with each other 6, lead The blower fan 7 and the tail gas treatment system 8 are composed. The continuous weighing system 1 and the automatic air distribution system 3 are connected to the feed device 22 and the air inlet of the sludge drying system 2, the discharge port of the sludge drying system 2 is connected to the air inlet of the solid-gas separation system 4, the discharge system 5, the air inlet The fan 7 is connected to the discharge port of the solid-gas ...

Embodiment 2

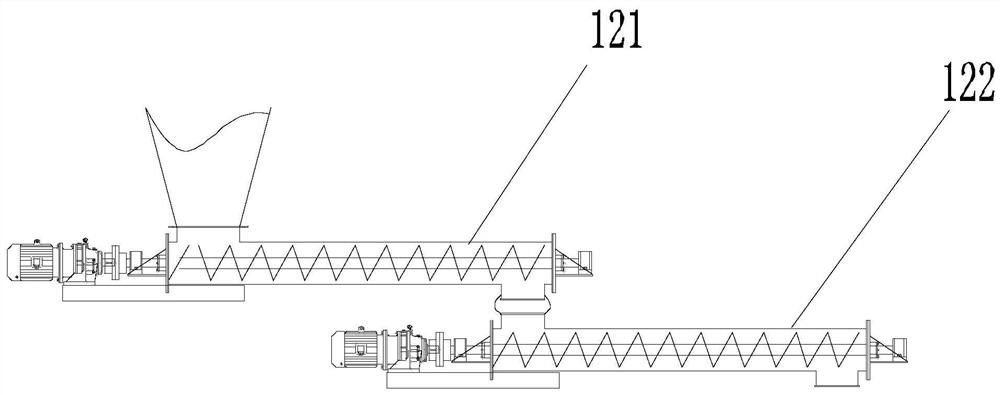

[0060] A kind of fully automatic hot air sludge drying equipment as shown in Example 1, the only difference is that, as image 3 As shown, the weighing device 12 is composed of a frequency conversion feeding screw machine 121 and a measuring screw scale 122, and a soft connection is adopted between the frequency conversion feeding screw machine 121 and the measuring screw scale 122.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com