Method for purifying molybdenum concentrate through microwave-acid leaching combined technologies

A compound process and technology of molybdenum concentrate, applied in the direction of improving process efficiency, etc., can solve the problems of inapplicable purification of molybdenum concentrate, easy oxidation of molybdenum sulfide, high production cost, etc., achieve remarkable impurity removal effect, improve reactivity, and facilitate The effect of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

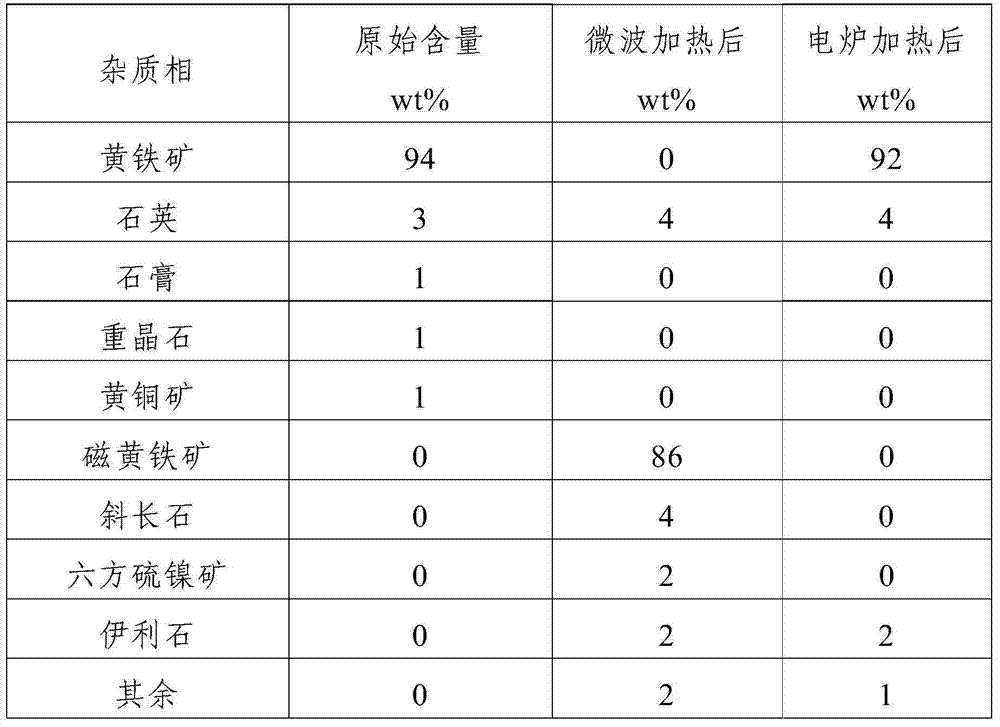

[0029] Purification of molybdenum concentrate by microwave-acid leaching composite process:

[0030] Step 1. Under the protection of a nitrogen atmosphere, microwave the molybdenum concentrate in a microwave atmosphere furnace; the temperature of the microwave heating treatment is 500° C., the time of the microwave heating treatment is 30 minutes, and the The frequency is 2.45GHz, the power of the microwave heating treatment is 30kW, and the MoS in the molybdenum concentrate 2 The mass percentage content is 90%;

[0031] Step 2, immerse the molybdenum concentrate after the microwave heating treatment in step 1 in the hydrochloric acid-hydrofluoric acid composite acid leaching solution according to the solid-to-liquid ratio of 1:1 to carry out acid leaching treatment, and the hydrochloric acid-hydrofluoric acid composite acid leaching solution is prepared by Hydrochloric acid, hydrofluoric acid and water are uniformly mixed in a volume ratio of 1:2:2, the mass percentage conce...

Embodiment 2

[0034] Purification of molybdenum concentrate by microwave-acid leaching composite process:

[0035] Step 1. Under the protection of a nitrogen atmosphere, microwave the molybdenum concentrate in a microwave atmosphere furnace; the temperature of the microwave heating treatment is 450° C., the time of the microwave heating treatment is 30 minutes, and the The frequency is 2.45GHz, the power of the microwave heating treatment is 20kW, and the MoS in the molybdenum concentrate 2 The mass percentage content is 88%;

[0036] Step 2, immerse the molybdenum concentrate after the microwave heating treatment in step 1 in the hydrochloric acid-hydrofluoric acid composite acid leaching solution according to the solid-to-liquid ratio of 1.05:1 to carry out acid leaching treatment, and the hydrochloric acid-hydrofluoric acid composite acid leaching solution is prepared by Hydrochloric acid, hydrofluoric acid and water are uniformly mixed in a volume ratio of 1:2:2, the mass percentage co...

Embodiment 3

[0039] Purification of molybdenum concentrate by microwave-acid leaching composite process:

[0040] Step 1. Under the protection of an inert atmosphere, microwave the molybdenum concentrate in a microwave atmosphere furnace; The frequency is 2.45GHz, the power of the microwave heating treatment is 10kW, and the MoS in the molybdenum concentrate 2 The mass percentage content is 92%;

[0041] Step 2, according to the solid-to-liquid ratio of 0.95: 1, the molybdenum concentrate after the microwave heating treatment in the step 1 is immersed in the hydrochloric acid-hydrofluoric acid composite acid leaching solution for acid leaching treatment, and the hydrochloric acid-hydrofluoric acid composite acid leaching solution is prepared by Hydrochloric acid, hydrofluoric acid and water are uniformly mixed in a volume ratio of 1:2:2, the mass percentage concentration of the hydrochloric acid is 32%, and the mass percentage concentration of the hydrofluoric acid is 42%, and then the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com