Method used for realizing dispersion uniform distribution of bismuth element in alloy steel containing bismuth

A technology of uniform distribution and alloy steel, which is applied in the manufacture of converters, etc., can solve the problems of no effective method for bismuth alloy, difficulty in dispersing to uniform distribution, difficulty in dissolving bismuth, etc., and achieves easy operation, simple equipment, and high yield. The effect of rate stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for dispersing and evenly distributing bismuth in the bismuth-containing alloy steel of embodiment 1 includes the following steps:

[0026] 1) Hot metal desulfurization treatment to reduce the sulfur element in the hot metal to the design value.

[0027] 2) Converter smelting, after tapping, first add 161kg of Al-Fe alloy to the ladle furnace containing 78 tons of molten steel, then add 2340kg of Ferrosilicon alloy, and then add 80kg of ladle slag modifier to modify the ladle slag to make the steel slag TFe+MnO The weight is 2.3% of the total weight of the ladle slag.

[0028] 3) Ladle refining, the temperature of the molten steel is controlled at 1573℃, and the weight percentage of the chemical components in the molten steel is controlled at: C: 0.030%, Si: 2.8%, Mn: 0.06%, P: 0.018%, S: 0.024% , Als: 0.03%.

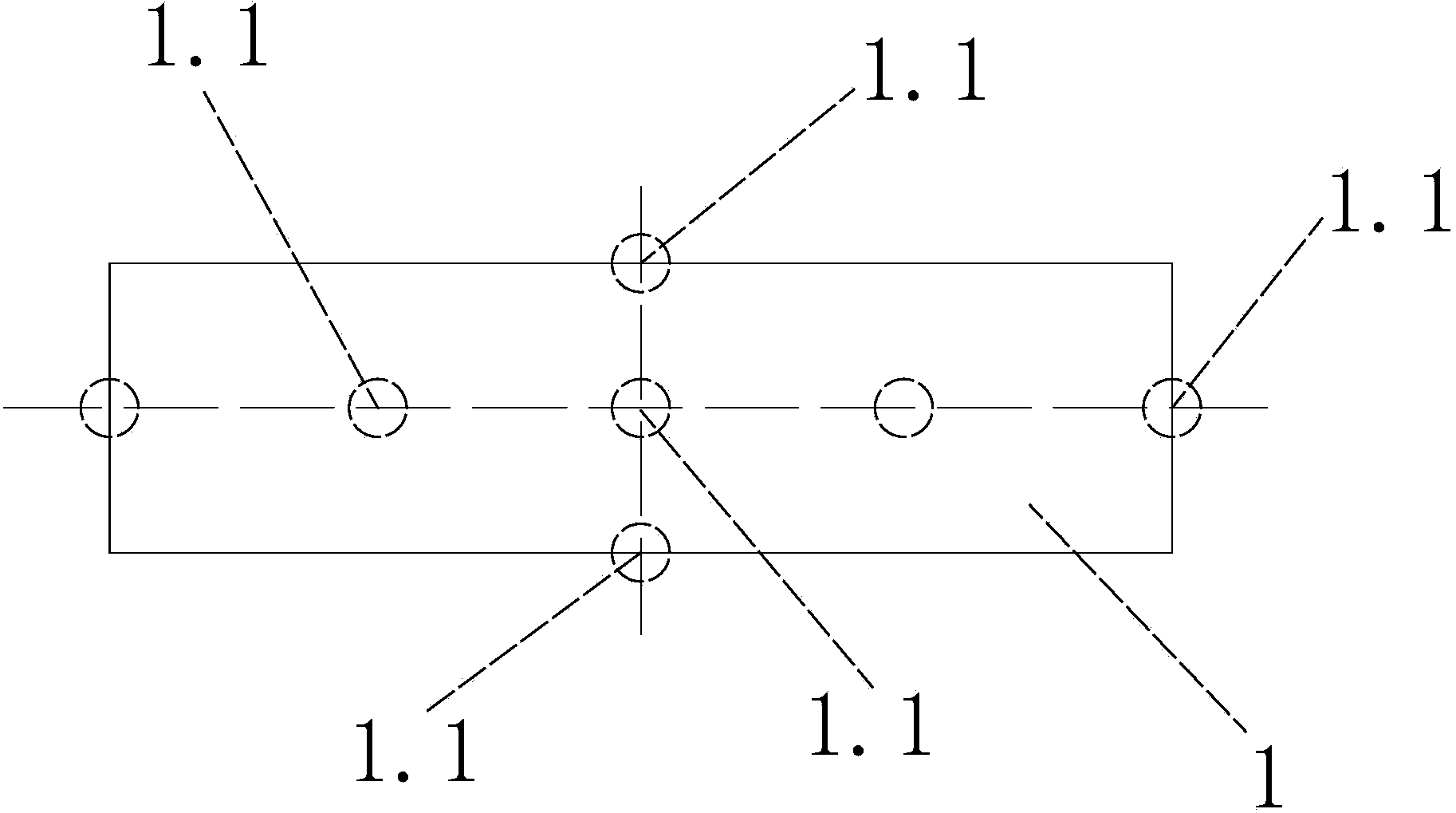

[0029] 4) After ladle refining, insert an alloy feed tube made of refractory material into the molten steel 175mm below the molten steel level, and add metal...

Embodiment 2

[0034] The method for dispersing and uniformly distributing bismuth in the bismuth-containing alloy steel of embodiment 2 includes the following steps:

[0035] 1) Hot metal desulfurization treatment to reduce the sulfur element in the hot metal to the design value.

[0036] 2) Converter smelting, after tapping, add 202kg of Al-Fe alloy to the ladle furnace containing 78 tons of molten steel, then add 2730kg of Ferrosilicon alloy, and then add 118kg of ladle slag modifier to modify the ladle slag to make the steel slag TFe+MnO The weight is 2.7% of the total weight of the ladle slag.

[0037] 3) Ladle refining, the temperature of the molten steel is controlled at 1592℃, and the weight percentage of the chemical components in the molten steel is controlled at: C: 0.065%, Si: 3.1%, Mn: 0.10%, P: 0.018%, S: 0.024% , Als: 0.02%.

[0038] 4) After ladle refining, insert the alloy feed tube made of refractory material into the molten steel 295mm below the molten steel level, and add the me...

Embodiment 3

[0043] The method for dispersing and uniformly distributing bismuth in the bismuth-containing alloy steel of embodiment 3 includes the following steps:

[0044] 1) Hot metal desulfurization treatment to reduce the sulfur element in the hot metal to the design value.

[0045] 2) Converter smelting, after tapping, first add 231kg of Al-Fe alloy to the ladle furnace containing 78 tons of molten steel, then add 3118kg of Ferrosilicon alloy, and then add 153kg of ladle slag modifier to modify the ladle slag to make the steel slag TFe+MnO The weight is 2.6% of the total weight of the ladle slag.

[0046] 3) Ladle refining, the temperature of the molten steel is controlled at 1581℃, and the weight percentage of the chemical components in the molten steel is controlled at: C: 0.090%, Si: 3.5%, Mn: 0.19%, P: 0.018%, S: 0.026% , Als: 0.04%.

[0047] 4) After ladle refining, insert an alloy feed tube made of refractory material into the molten steel 220mm below the molten steel level, and add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com