Super deep desulfurization combined method for FCC (fluid catalytic cracking) gasoline

A combined method and deep desulfurization technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of long hydrodesulfurization process route, low sulfur capacity of adsorbent, frequent regeneration of adsorbent, etc., to achieve guaranteed Long-term stable operation, high activity, high adsorption selectivity and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

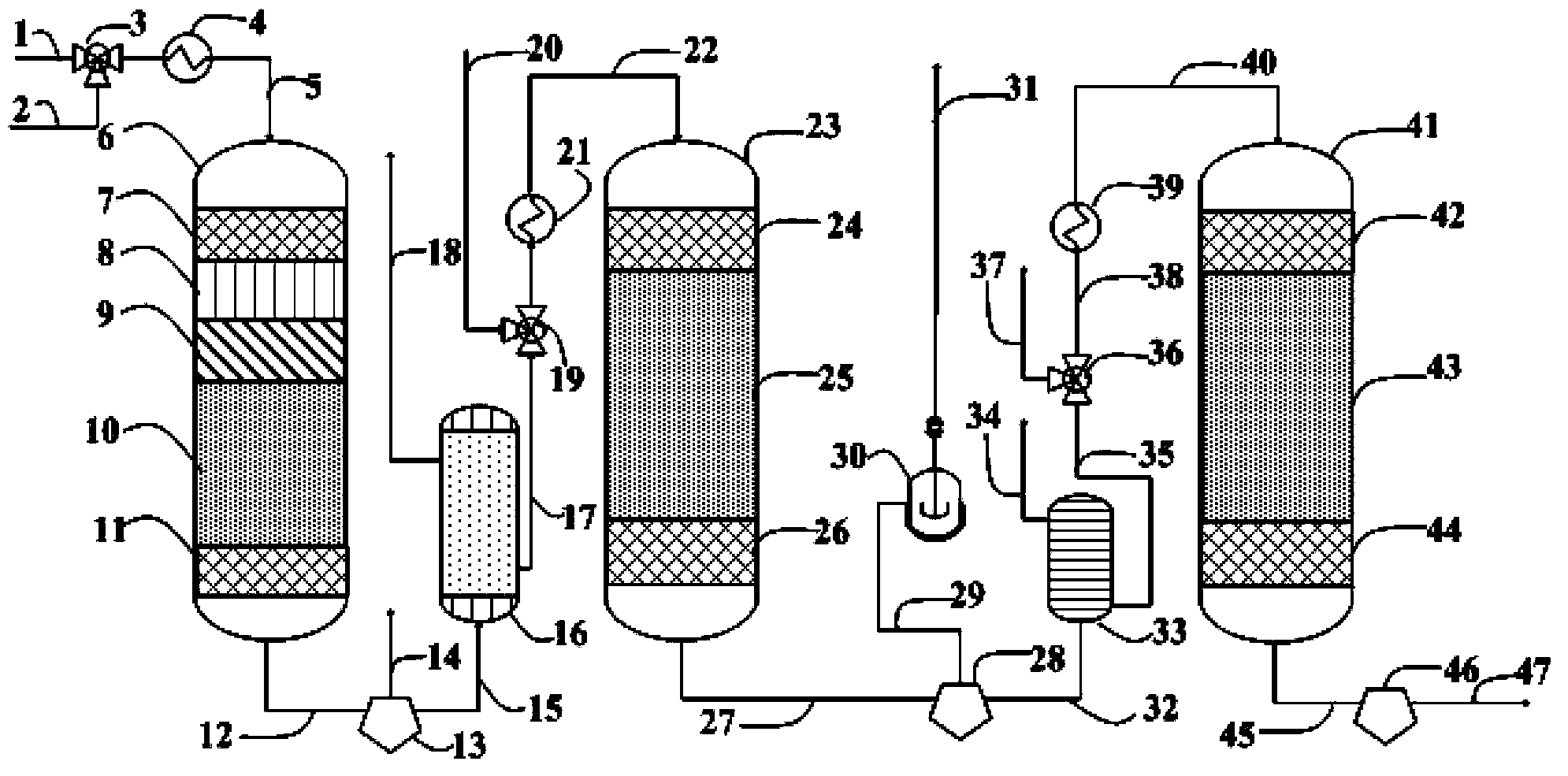

Method used

Image

Examples

preparation example Construction

[0054] 1. Preparation of protective agent 1: impregnate 100 grams of alumina carrier with 116 ml of a solution containing 0.44 grams of potassium hydroxide, dry at 120 degrees and roast at 450 degrees, then impregnate 5.95 grams of nickel nitrate and 3.72 grams of ammonium molybdate 85 milliliters of co-impregnation solution, after drying at 120 degrees and roasting at 450 degrees, the protective agent 1 is obtained, and its composition is 1.43wt%NiO-2.86wt%-0.30wt% / Al 2 o 3 . The preparation method of the protective agent 1 used in the following examples 1-8 is exactly the same, except that the content of each component is different.

[0055] 2. Preparation of protective agent 2: impregnate 100 grams of alumina carrier with 100 ml of a solution containing 0.92 grams of potassium hydroxide, dry at 120 degrees and roast at 450 degrees, then impregnate 11.90 grams of nickel nitrate and 7.44 grams of ammonium molybdate 70 milliliters of the co-impregnation solution, after dryin...

Embodiment 1

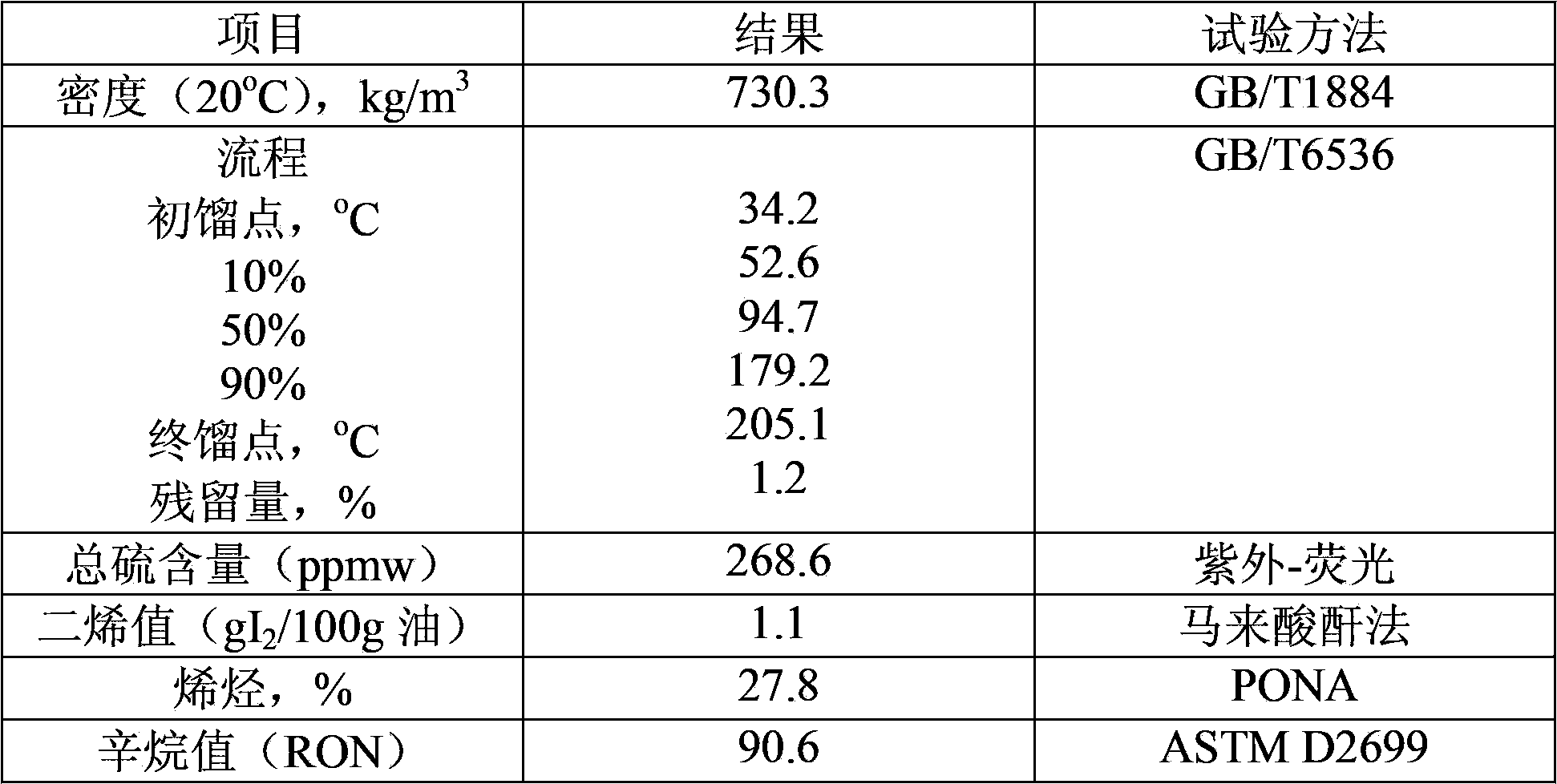

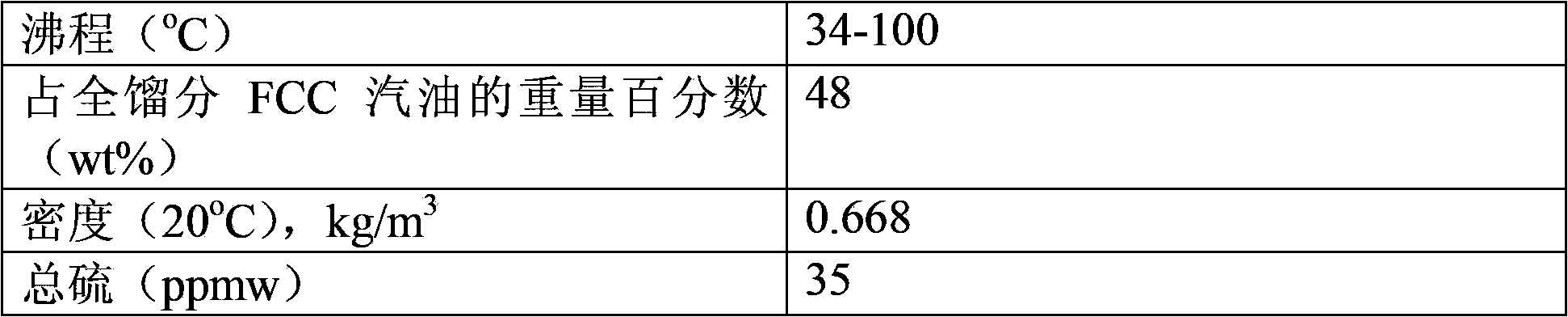

[0075] The full-cut FCC gasoline with the properties described in Table 1 is mixed with hydrogen and then enters the de-diene reactor after heat exchange through a heat exchanger. The de-diene reactor is filled with protective agent 1 (1.2%NiO-2.4%MoO 3 -0.28%K 2 O / Al 2 o 3 ) 2.5mL, protective agent 2 (2.8%NiO-5.2%MoO 3 -0.8%K 2 O / Al 2 o 3 ) 2.5mL, de-diene catalyst (16.2%NiO-18.2%ZnO-10.4%MoO 3 -13.5% WO 3 -5.2%Al 2 o 3 -2.4%TiO 2 -3.2%K 2 O / 30.9%SiO 2 -Al 2 o 3 ) 10mL, before the oil and hydrogen enter the diene reactor, the protective agent and the diene catalyst should be pre-sulfurized in the reactor. The vulcanization condition is to use straight-run gasoline containing 2wt% carbon disulfide to presulfurize the catalyst. The specific vulcanization conditions are hydrogen partial pressure 1.6MPa, temperature 290°C, liquid hourly space velocity 2.0h -1 , the volume ratio of hydrogen to oil is 300, and the vulcanization time is 9 hours. After the sulfidation...

Embodiment 2

[0077] The protective agent, diene removal catalyst, selective hydrodesulfurization catalyst and adsorbent used are the same as in Example 1, except that the diene removal process conditions become 100°C of reaction temperature, hydrogen partial pressure of 1.4MPa, and hydrogen-to-oil volume ratio of 80NL / L , night time space speed 3.0h -1 . Sampling analysis after reacting 500 hours, finds diene value from 1.1gI 2 / 100g oil drops below 0.1. The selected hydrodesulfurization process conditions become reaction temperature 280°C, hydrogen partial pressure 1.2MPa, hydrogen-oil volume ratio 100NL / L, night time space velocity 2.5h -1 . Adsorption desulfurization process conditions become adsorption temperature 300°C, hydrogen partial pressure 1.4MPa, hydrogen-oil volume ratio 50NL / L, night time space velocity 3.0h -1 . Sampling and analysis after 500 hours of reaction revealed that the total sulfur content had dropped from 268.6ppmw of the feedstock to 7.6ppmw, while the octan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com