Ammonia nitrogen adsorbent and preparation method and application method thereof

An adsorbent, ammonia nitrogen technology, applied in the field of environmental engineering, can solve the problems of slow growth of nitrifying bacteria, high price of chemical reagents, huge treatment facilities, etc., to achieve stable effluent water quality, easy analysis and regeneration, good economic and environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

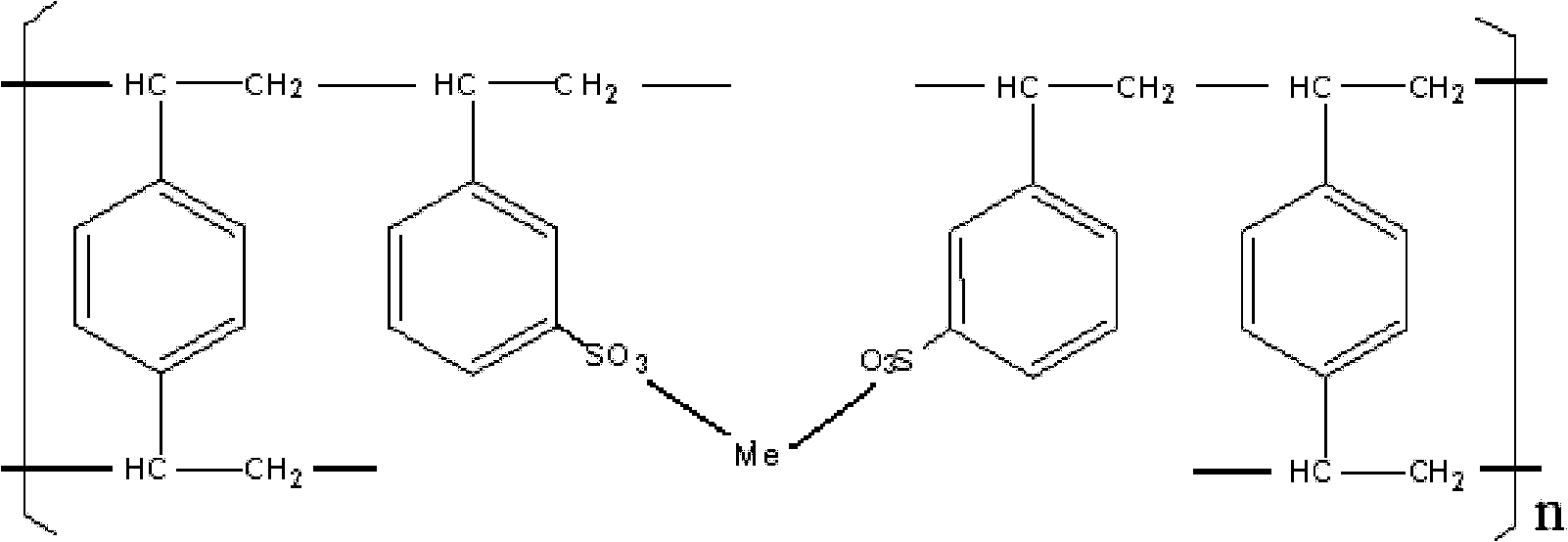

[0033] Mix 1 L of the chelating resin shown in structural formula 3 fully soaked in pure water with 2 L of 1 mol / L copper sulfate saturated solution, stir and react for 30 minutes, backwash the copper ions on the surface of the resin with pure water, and bake the resin at 40 ° C. After drying for 48 hours, the ammonia nitrogen adsorbent was obtained.

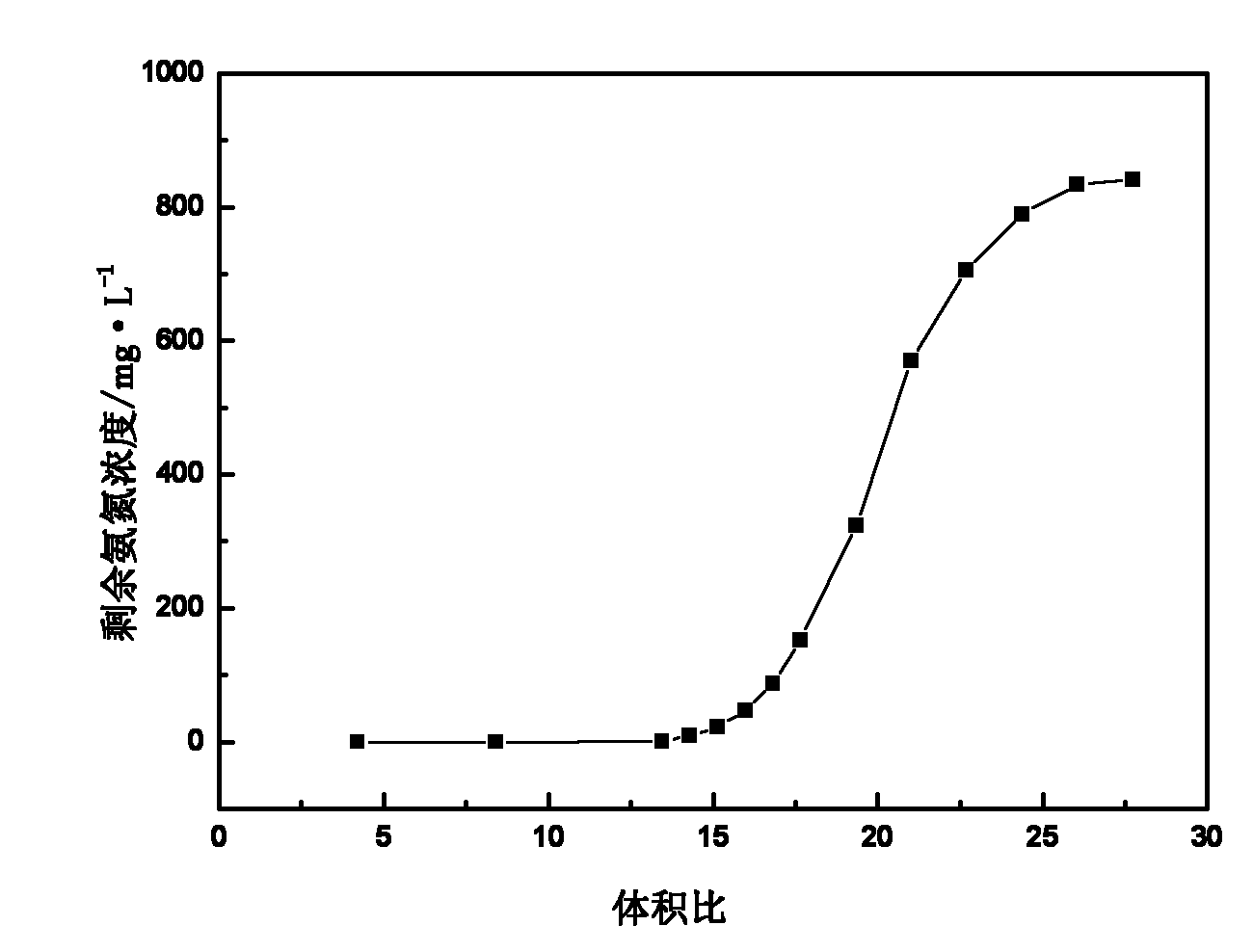

[0034] 30g of ammonia nitrogen adsorbent (dry) was filled into the ion exchange column, and the ammonia nitrogen concentration was 840mg / L ammonia solution through the exchange column at a flow rate of 5mL / min, figure 1 The ammonia nitrogen outflow curve is given.

[0035] Put the saturated ammonia nitrogen adsorbent into a container filled with 100mL of pure water, gradually add 1mol / L hydrochloric acid, when the pH of the solution drops to 2-6, preferably 3-5, stop adding acid, and after analysis The ammonia nitrogen adsorbent was repacked for use. The desorption liquid can be used repeatedly for the desorption of the ammoni...

Embodiment 2

[0038] Mix 1 L of the chelating resin shown in structural formula 3 fully soaked in pure water with 2 L of 1 mol / L zinc sulfate saturated solution, stir for 30 minutes, backwash the zinc ions on the surface of the resin with pure water, and dry the resin at 40 ° C. After drying for 48 hours, the ammonia nitrogen adsorbent was obtained.

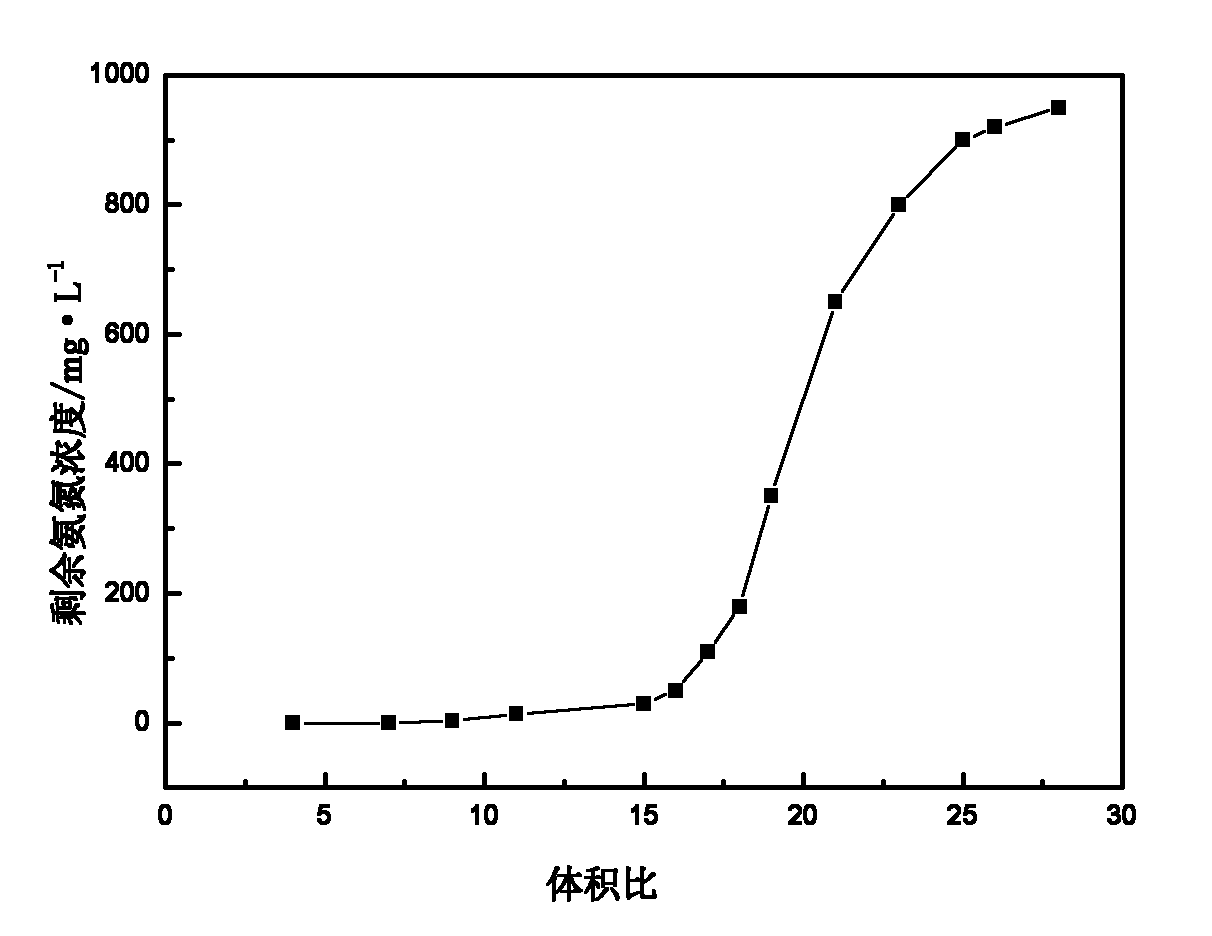

[0039] 30g of ammonia nitrogen adsorbent (dry) was filled into the ion exchange column, and the ammonia nitrogen concentration was 840mg / L ammonia solution through the exchange column at a flow rate of 5mL / min, figure 2 The ammonia nitrogen outflow curve is given.

[0040] Put the saturated ammonia nitrogen adsorbent into a container filled with 100mL of pure water, and gradually add 1mol / L hydrochloric acid. When the pH of the solution drops to 2-6, preferably 3-5, stop adding acid. The ammonia nitrogen adsorbent was repacked for use. The desorption liquid can be used repeatedly for the desorption of the ammonia nitrogen saturated resin. W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com