High melt strength polypropylene (PP) prepared by pre-irradiation technology and preparation method thereof

A high melt strength, polypropylene technology, applied in the field of polymer composite materials, can solve the problems of low melt viscosity and melt strength, low bubble wall strength, difficult to blow film, etc., to achieve simple preparation process, melt strength High, simple raw material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high melt strength polypropylene obtained by reactive extrusion of a polypropylene composition of:

[0030] 1 part of low-density polyethylene, the pre-irradiation dose is 100kGy; 99 parts of polypropylene.

[0031] The preparation method of above-mentioned high melt strength polypropylene:

[0032] The raw materials are mixed evenly in a high-speed mixer according to the composition ratio, and then passed through a twin-screw extruder with a length-to-diameter ratio of L / D=40 and a diameter of 35mm, and melt-extruded at a screw speed of 100 rpm and a reaction temperature of up to 170°C. Pelletizing to obtain high melt strength polypropylene resin.

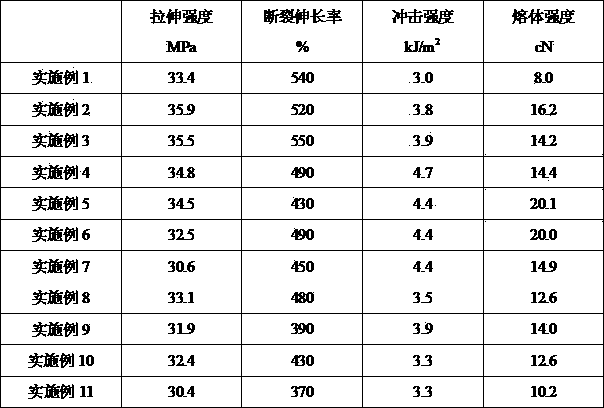

[0033] The properties and melt strength results of the samples are shown in Table 1.

[0034]

Embodiment 2

[0036] A high melt strength polypropylene obtained by reactive extrusion of a polypropylene composition of:

[0037] 3 parts of linear low density polyethylene, pre-irradiation dose of 100kGy; 97 parts of polypropylene.

[0038] The preparation method of above-mentioned high melt strength polypropylene:

[0039] The raw materials are mixed evenly in a high-speed mixer according to the composition ratio, and then passed through a twin-screw extruder with a length-to-diameter ratio of L / D=40 and a diameter of 35mm, and melt-extruded at a screw speed of 100 rpm and a reaction temperature of up to 190°C. Pelletizing to obtain high melt strength polypropylene resin.

[0040] The properties and melt strength results of the samples are shown in Table 1.

[0041]

Embodiment 3

[0043] A high melt strength polypropylene obtained by reactive extrusion of a polypropylene composition of:

[0044] 3 parts of high-density polyethylene, pre-irradiation dose of 100kGy; 99 parts of polypropylene.

[0045] The preparation method of above-mentioned high melt strength polypropylene:

[0046] The raw materials are mixed evenly in a high-speed mixer according to the composition ratio, and then passed through a twin-screw extruder with a length-to-diameter ratio of L / D=40 and a diameter of 35mm, and melt-extruded at a screw speed of 100 rpm and a reaction temperature of up to 170°C. Pelletizing to obtain high melt strength polypropylene resin.

[0047] The properties and melt strength results of the samples are shown in Table 1.

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com