Cationic ethylene-vinyl acetate copolymer emulsion and production method thereof

A vinyl acetate and copolymer emulsion technology, applied in the field of cationic ethylene-vinyl acetate copolymer emulsion and its synthesis, can solve the problems of no industrialized products, no cationic VAE emulsion, etc., and achieves hard precipitation, excellent mechanical stability, stable good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

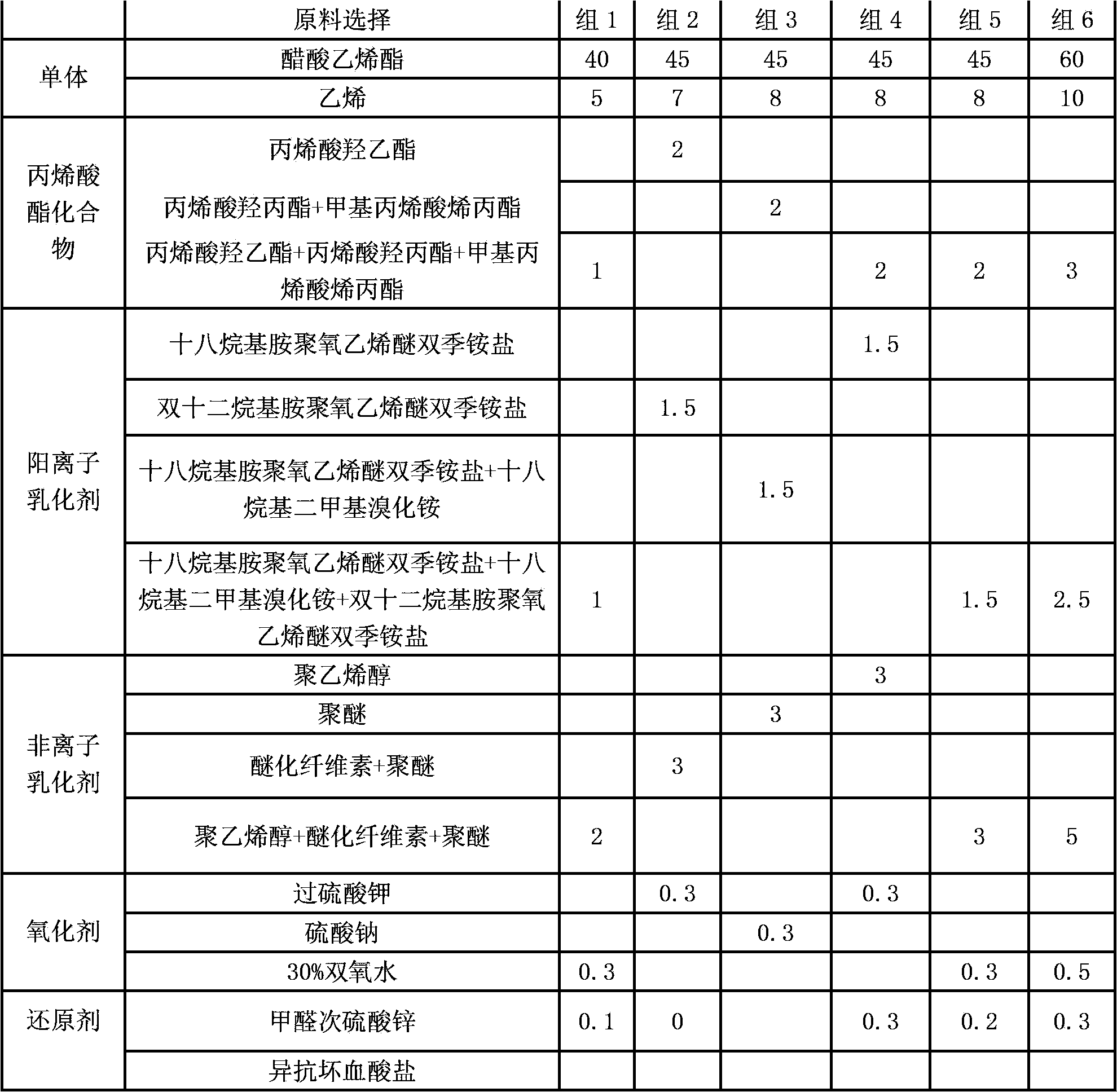

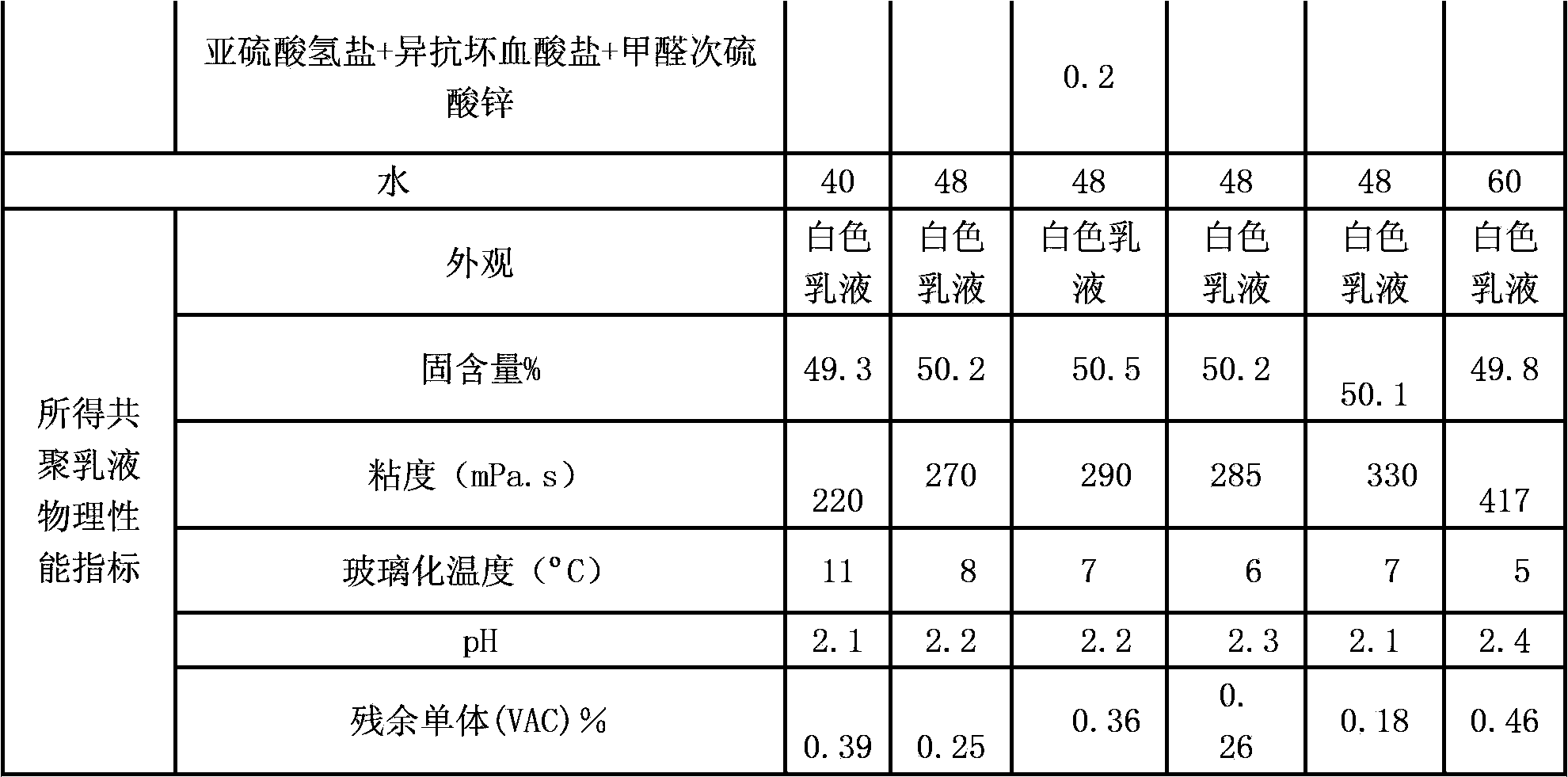

Examples

Embodiment 1

[0037] A kind of synthetic method of cationic ethylene-vinyl acetate copolymer emulsion, it is characterized in that: adopt above-mentioned each raw material component; It is prepared by comprising following preparation steps, wherein, described parts or percentages are mass parts:

[0038] (1) Pre-reaction preparation

[0039] Prepare emulsifier solution: add 3 parts of compound emulsifier (including 1 part of stearylamine polyoxyethylene ether diquaternary ammonium salt, 2 parts of polyvinyl alcohol) and 30 parts of deionized water into the reactor, start stirring, After mixing thoroughly, heat up to dissolve completely;

[0040] Preparation of initiator solution: a) Add 0.3 parts of ammonium persulfate and 5 parts of deionized water to initiator tank A and stir for 15 minutes to make initiator solution; b) Add 0.1 part of zinc formaldehyde sulfoxylate into reducing agent tank B , Stir 5 parts of deionized water for 15 minutes to prepare a reducing agent solution;

[0041]...

Embodiment 2

[0049] A kind of synthetic method of cationic ethylene-vinyl acetate copolymer emulsion, it is characterized in that: adopt above-mentioned each raw material component; It is prepared by comprising following preparation steps, wherein, described parts or percentages are mass parts:

[0050] (1) Pre-reaction preparation

[0051] Prepare emulsifier solution: add 5 parts of compound emulsifier (including 2 parts of didodecylamine polyoxyethylene ether diquaternary ammonium salt, 2 parts of polyether and 1 part of polyvinyl alcohol), 40 parts of deionized water, start stirring, mix well and heat up to make it completely dissolve;

[0052] Preparation of initiator solution: a) Add 0.3 parts of potassium persulfate and 5 parts of deionized water to initiator tank A and stir for 15 minutes to make initiator solution; b) Add 0.2 parts of sodium bisulfite, Stir 5 parts of deionized water for 15 minutes to prepare a reducing agent solution;

[0053] Preparation of mixed monomer: add 5...

Embodiment 3

[0061] A kind of synthetic method of cationic ethylene-vinyl acetate copolymer emulsion, it is characterized in that: adopt above-mentioned each raw material component; It is prepared by comprising following preparation steps, wherein, described parts or percentages are mass parts:

[0062] (1) Pre-reaction preparation

[0063] Prepare emulsifier solution: add 7.5 parts of compound emulsifier (including 2.5 parts of octadecyldimethylammonium bromide, 3 parts of polyether, 2 parts of etherified cellulose to 5 parts), 40 parts of deionized water, start stirring, mix well and heat up to make it completely dissolve;

[0064] Preparation of initiator solution: a) Add 0.5 parts of hydrogen peroxide (30%wt) and 10 parts of deionized water to initiator tank A and stir for 15 minutes to make initiator solution; b) Add 0.1 part of formaldehyde in initiator tank B Zinc sulfoxylate and 10 parts of deionized water were stirred for 15 minutes to form a reducing agent solution;

[0065] Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com