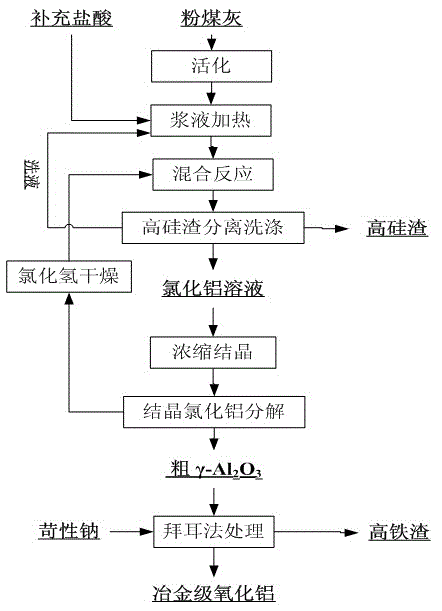

A method for preparing alumina by treating fly ash with hydrochloric acid

A technology of fly ash and alumina, which is applied to the removal of alumina/hydroxide and solid waste, can solve problems such as secondary pollution, high energy consumption, and potential safety hazards for operators, so as to facilitate industrialization and ensure Hydrochloric acid concentration, the effect of avoiding corrosion hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The fly ash is mechanically activated by a vibrating mill, and 5% supplementary hydrochloric acid and washing liquid are mixed with the fly ash to form a slurry, which is indirectly heated to 160°C with saturated steam in an indirect heat exchanger and then sent to the lining for acid resistance. In the reactor of ceramic tiles, feed the hydrogen chloride gas recovered by drying concentrated sulfuric acid, the molar ratio of hydrogen chloride and the sum of HCl in the supplementary hydrochloric acid to the sum of aluminum oxide and iron oxide in the fly ash is 6.5, the reaction time is 2h, and the reaction solidifies after cooling down. Liquid separation to obtain aluminum chloride liquid. The solid-liquid separation of aluminum chloride solution and high-silicon slag adopts flocculation and sedimentation. The aluminum chloride liquid is spray-dried to obtain crystalline aluminum chloride. The aluminum chloride crystal is decomposed at 400°C to obtain crude γ -Al 2 o 3...

Embodiment 2

[0028] The raw material fly ash in Example 1 is mechanically activated by a vertical mill, and 10% supplementary hydrochloric acid and lotion are mixed with fly ash to form a slurry, which is indirectly heated to 190°C with superheated steam in an indirect heat exchanger After that, it is sent into a reactor lined with enamel, and the hydrogen chloride gas recovered by drying concentrated sulfuric acid is introduced. The molar ratio of hydrogen chloride and the HCl in the above-mentioned supplementary hydrochloric acid to the sum of aluminum oxide and iron oxide in fly ash is 7.5, and the reaction time is 3h, solid-liquid separation after reaction cooling, to obtain aluminum chloride liquid, solid-liquid separation of aluminum chloride solution and high-silicon slag adopts flocculation sedimentation, aluminum chloride liquid adopts drum drying to obtain crystalline aluminum chloride, aluminum chloride crystals in Decompose at 500℃ to get crude γ-Al 2 o 3 And hydrogen chloride...

Embodiment 3

[0030]The raw material fly ash in Example 1 is mechanically activated by a planetary mill, and 8% concentration supplemented hydrochloric acid and lotion are mixed with fly ash to form a slurry, which is indirectly heated to 200°C with heat transfer oil in an indirect heat exchanger and sent to Into the reactor lined with glass, pass through the hydrogen chloride gas recovered by drying concentrated sulfuric acid, the molar ratio of hydrogen chloride and the sum of HCl in the above-mentioned supplementary hydrochloric acid and the sum of aluminum oxide and iron oxide in the fly ash is 9, and the reaction time is 1h. After the reaction cools down, solid-liquid separation is obtained to obtain aluminum chloride liquid. The solid-liquid separation of aluminum chloride solution and high-silicon slag adopts flocculation and sedimentation, and the aluminum chloride liquid adopts forced circulation evaporation crystallization to obtain crystalline aluminum chloride. Decompose at ℃ to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com