Sliding rail device for steel-structure roof opening

A technology of steel structure and slide rail, which is applied in the direction of roof, roof cladding, building structure, etc., can solve the problems that the stability of the structure cannot be guaranteed, and achieve the effects of alleviating the hidden danger of water leakage, enhancing the rigidity, and facilitating locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

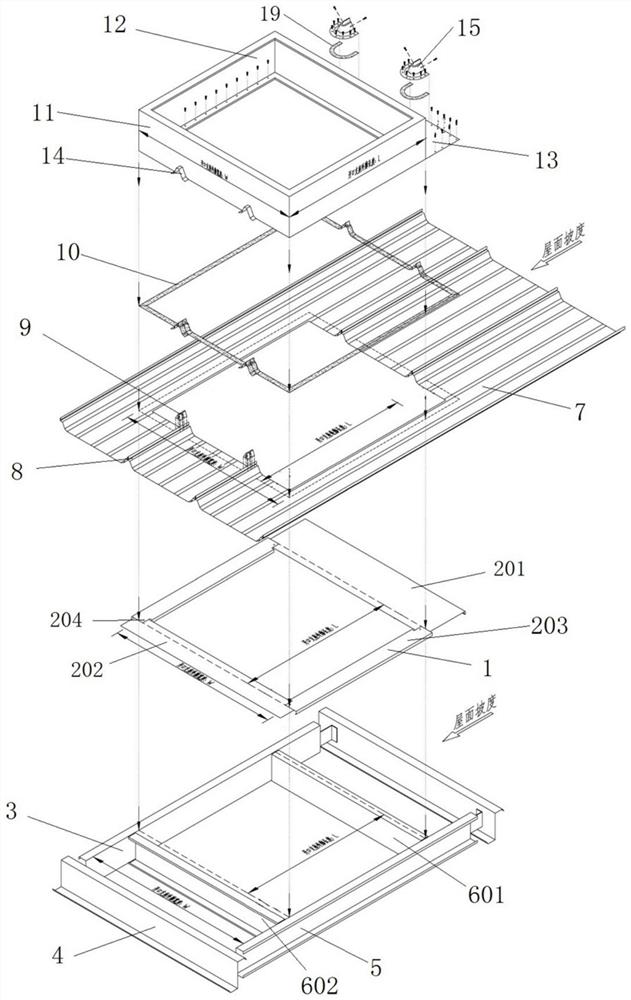

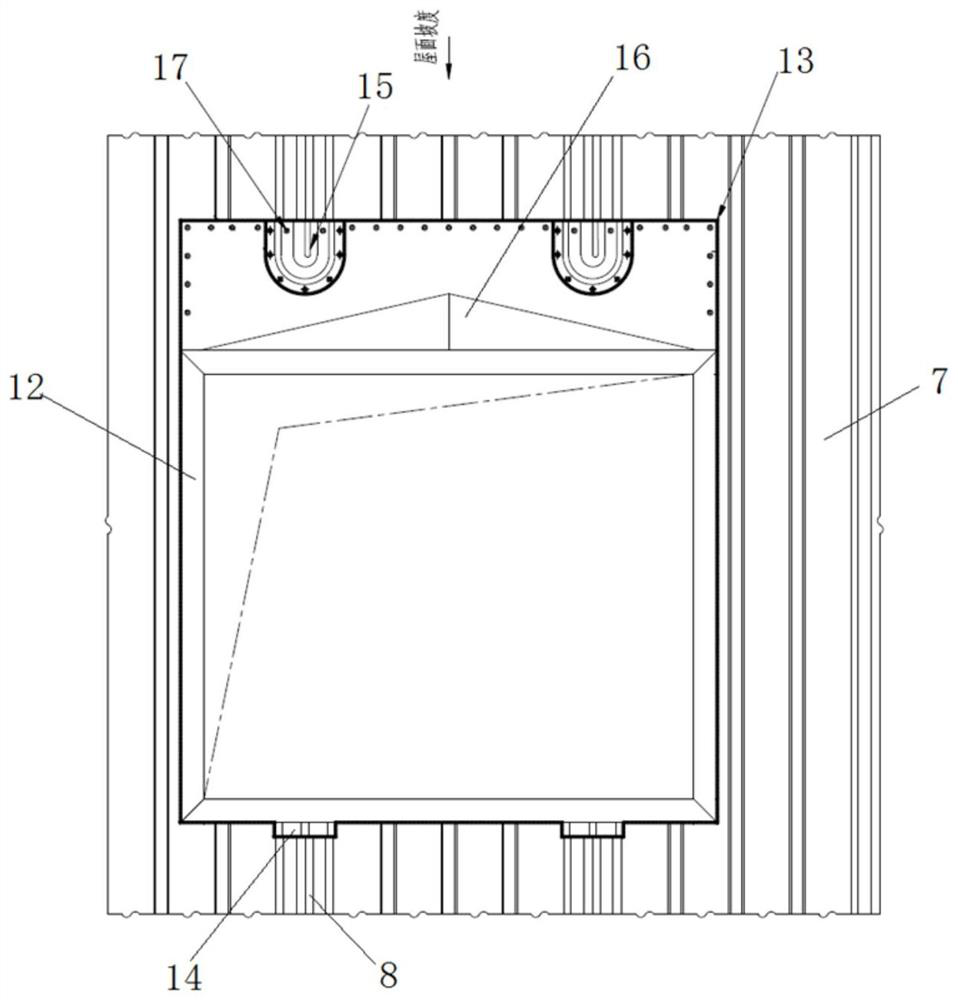

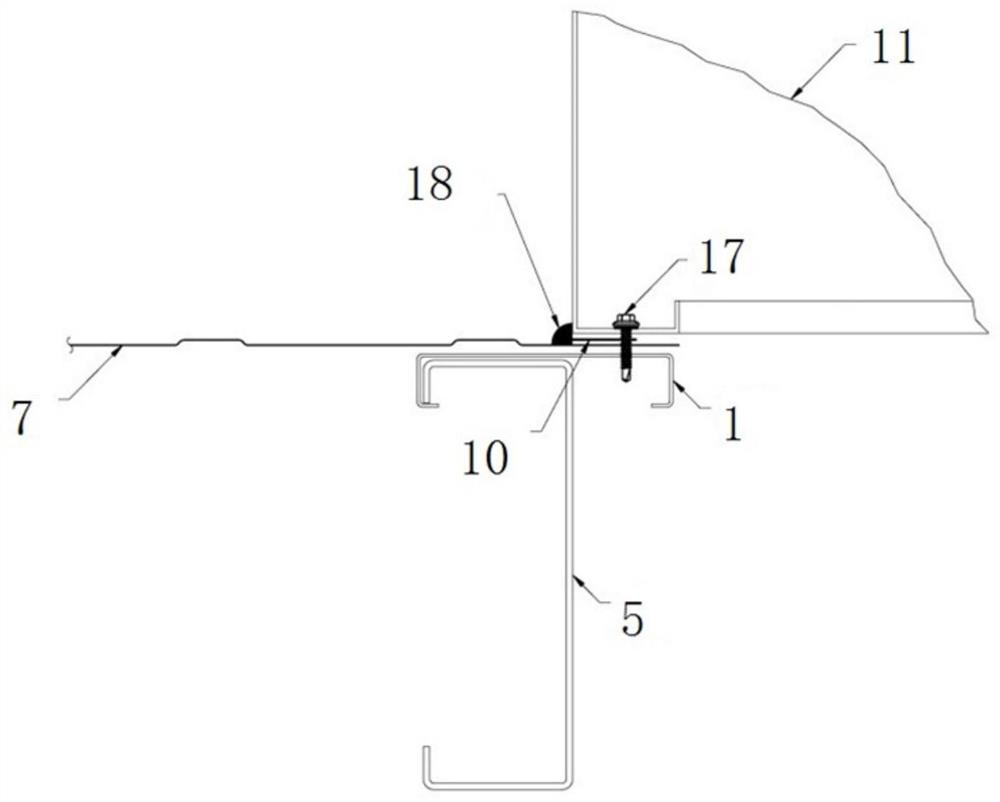

[0030] Such as figure 1 As shown, the present application proposes a slide rail device for a roof opening of a steel structure, and the slide rail device is arranged between the roof opening frame 3 and the roof panel 7 .

[0031] The roof opening frame 3 is arranged between two adjacent roof purlins 4, including the opening frame upper opening C-shaped purlin 601 located at the upper opening of the roof opening, the opening frame lower opening C-shaped purlin 602 located at the lower opening of the opening, and the opening left and right two purlins. Two open frame side C-shaped purlins 5 on the side.

[0032] The slide rail device 1 is installed above the roof opening frame 3 and includes: an upper J-shaped member 201 located at the upper opening of the opening, a lower J-shaped member 202 located at the lower opening of the opening, and C-shaped slide rails 203 located at the left and right sides of the opening. The opening of the C-shaped slide rail 203 is downward, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com