Method for rough turning turbine seal sleeve made of high-temperature alloy GH901

A technology of high temperature alloy and steam sealing sleeve, applied in twist drills and other directions, can solve the problems of difficult processing, difficult processing and scrapped products, etc., and achieve high temperature hardness, economy and efficiency guarantee, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

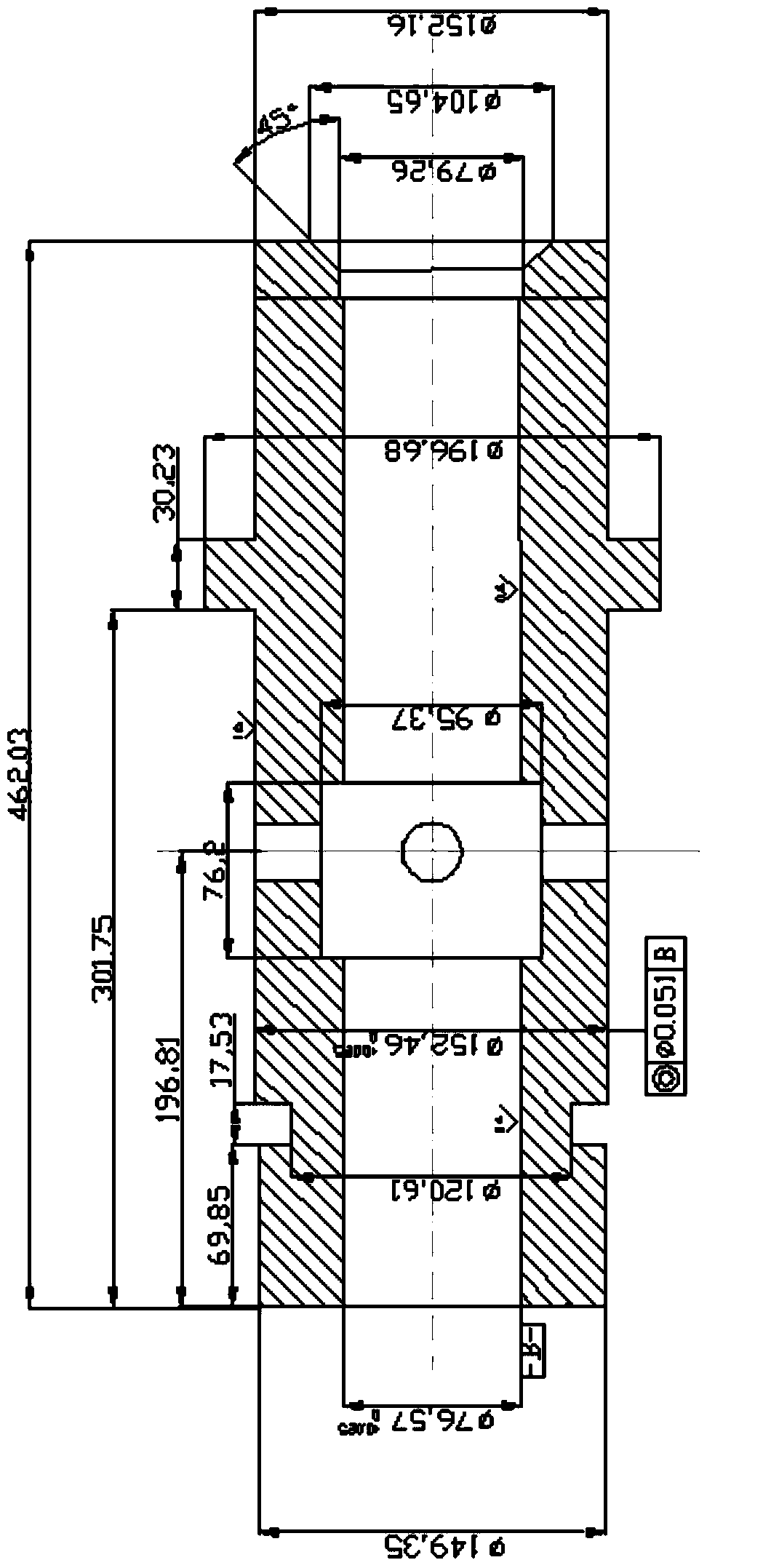

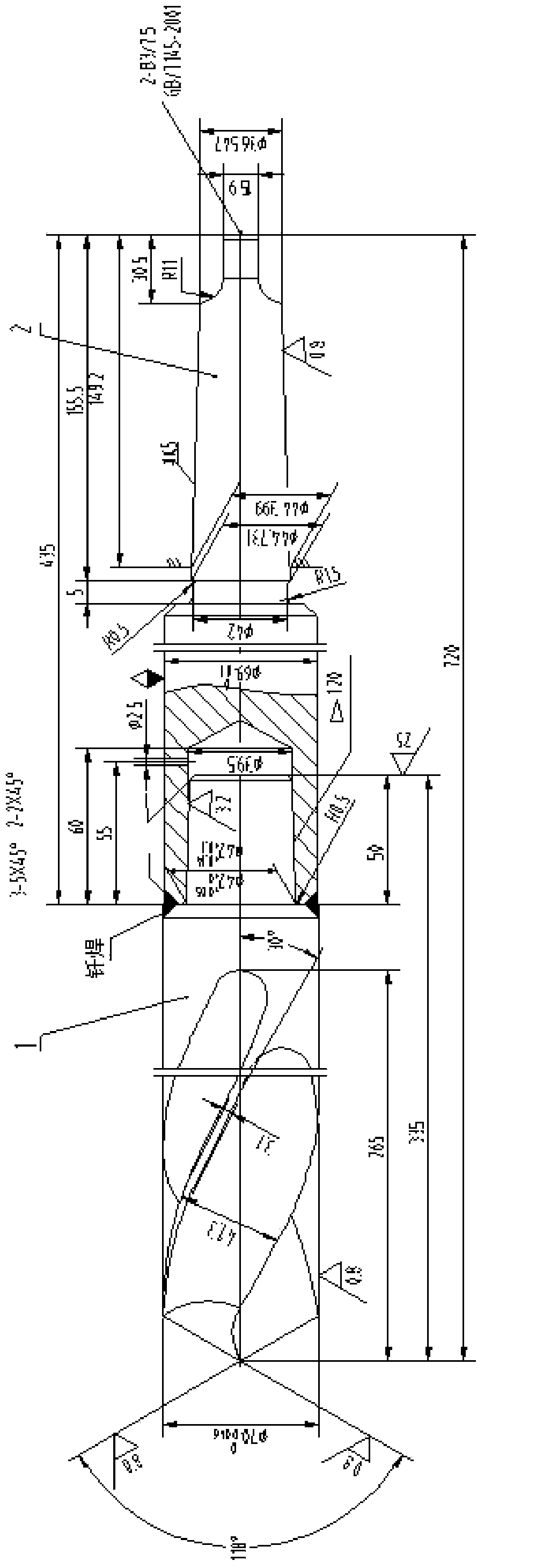

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode one: the rough turning method of the steam turbine steam seal sleeve of superalloy GH901 material in this implementation mode is carried out according to the following steps:

[0016] 1. Rough turning outer circle: cutting parameters are: when the allowance on one side > 4mm: f = 0.1mm / r, ap < 0.5mm, V = 0.642m / s; when 0.5mm < allowance on one side < 4mm : f=0.1mm / r, ap<0.2mm, V=0.642m / s; when single-sided allowance<0.50mm: f=0.1mm / r, ap<0.10mm, V=0.642m / s;

[0017] 2. Drilling the inner hole: the inner hole drill tool used is φ55 extended drill or φ70 extended drill, and the drill bit material is W6Mo5Cr4V2Al;

[0018] 3. Inner hole: The cutting parameters are: when the allowance on one side > 4mm: f = 0.1mm / r, ap < 0.5mm, V = 0.642m / s; when 0.5mm < allowance on one side < 4mm: f=0.1mm / r, ap<0.2mm, V=0.642m / s; when the one-sided margin<0.50mm: f=0.1mm / r, ap<0.10mm, V=0.642m / s.

[0019] According to the rough turning method of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com