Particle surface treating plant

A technology for processing equipment and particle surfaces, which is applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problem of demanding particle properties, low universal applicability of particle fluidization, uneven contact time of particles of various particle sizes, etc. problem, to achieve the effect of stability, easy control, enhanced dispersion, and large axial space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

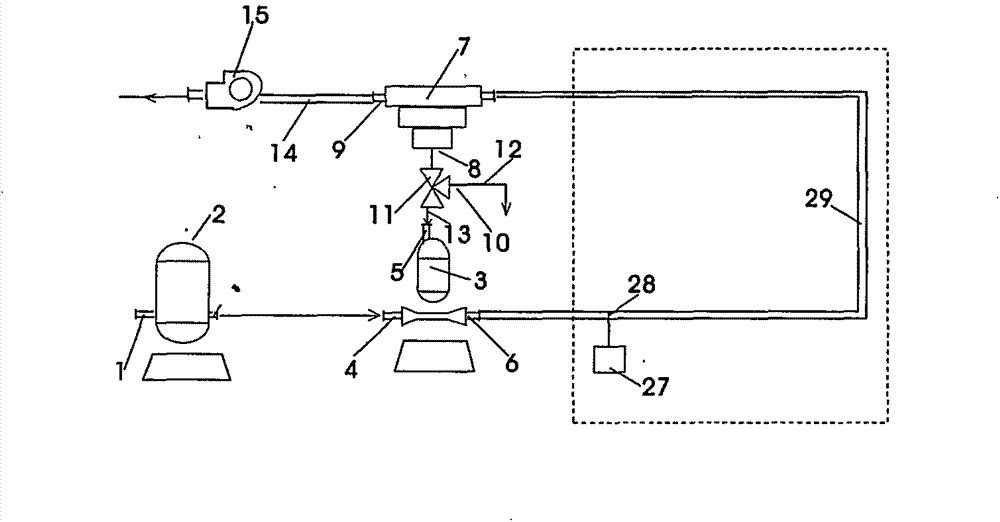

[0022] Such as figure 1 Shown is the first principle diagram of the pressure-feeding particle surface treatment equipment according to the present invention. The pressure-feeding pneumatic conveying system of material circulation is used as the particle fluidization equipment, and the particle is fluidized and surface treated by this equipment. It includes an air supply device 2 , a feeding device 3 , a delivery pipeline between the feeding device 3 and a discharge device 7 , a discharge device 7 , and an exhaust pipe 14 . Wherein, the feeding device 3 has a first gas inlet 4 and a second solid particle inlet 5, the first gas inlet 4 of the feeding device is connected with the gas supply device 2, and the outlet 6 of the feeding device is connected with the conveying pipeline, and the downstream of the conveying pipeline is Connected with the discharge device 7, the gas will be sent into the feed device 3 and the downstream conveying pipeline accordingly; the second inlet 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com