Sc2O3-stabilized ZrO2-based electrolyte powder and preparation method thereof, and Sc2O3-stabilized ZrO2 electrolyte ceramic wafer prepared from powder

An electrolyte powder, sc2o3 technology, applied in the direction of solid electrolyte fuel cells, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as difficult industrialized mass production, expensive raw materials, unsuitable for industrialized production, etc., and achieve process continuous efficiency High, guaranteed purity, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

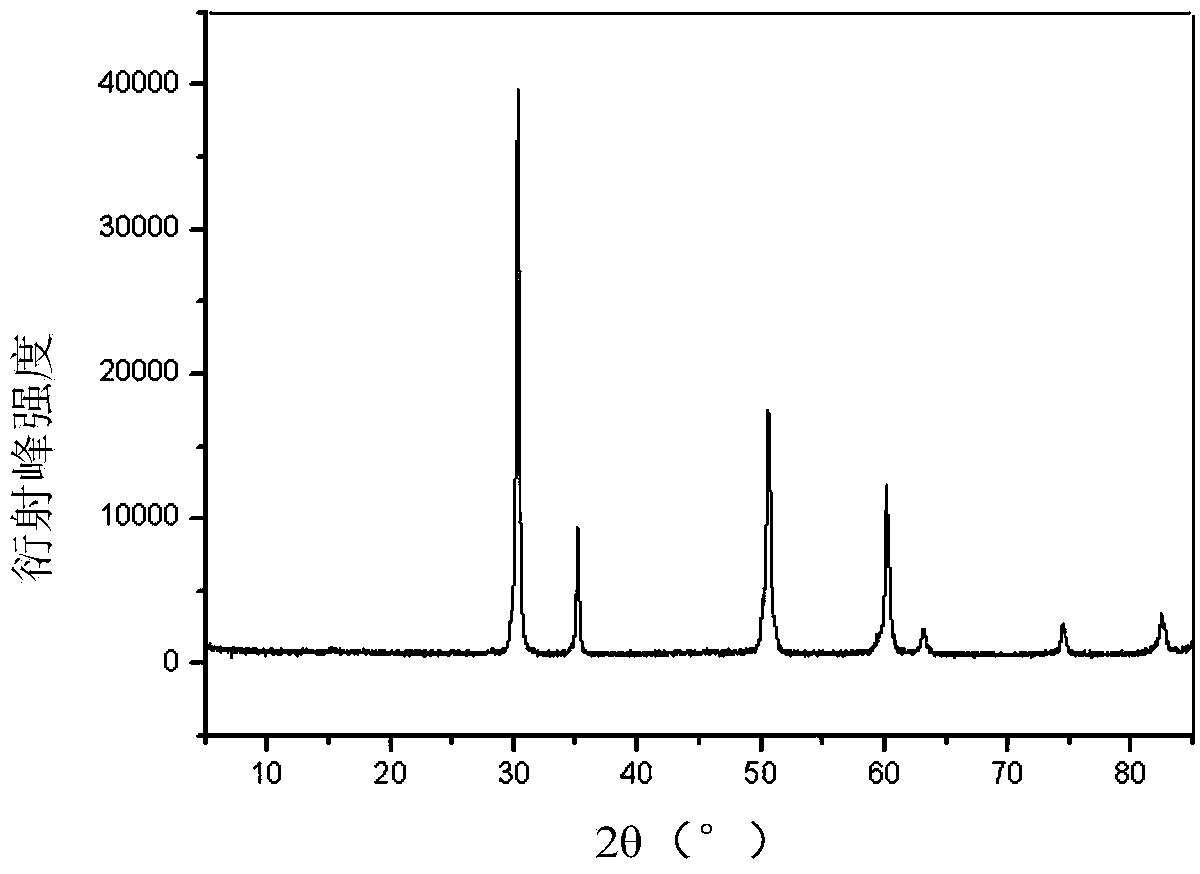

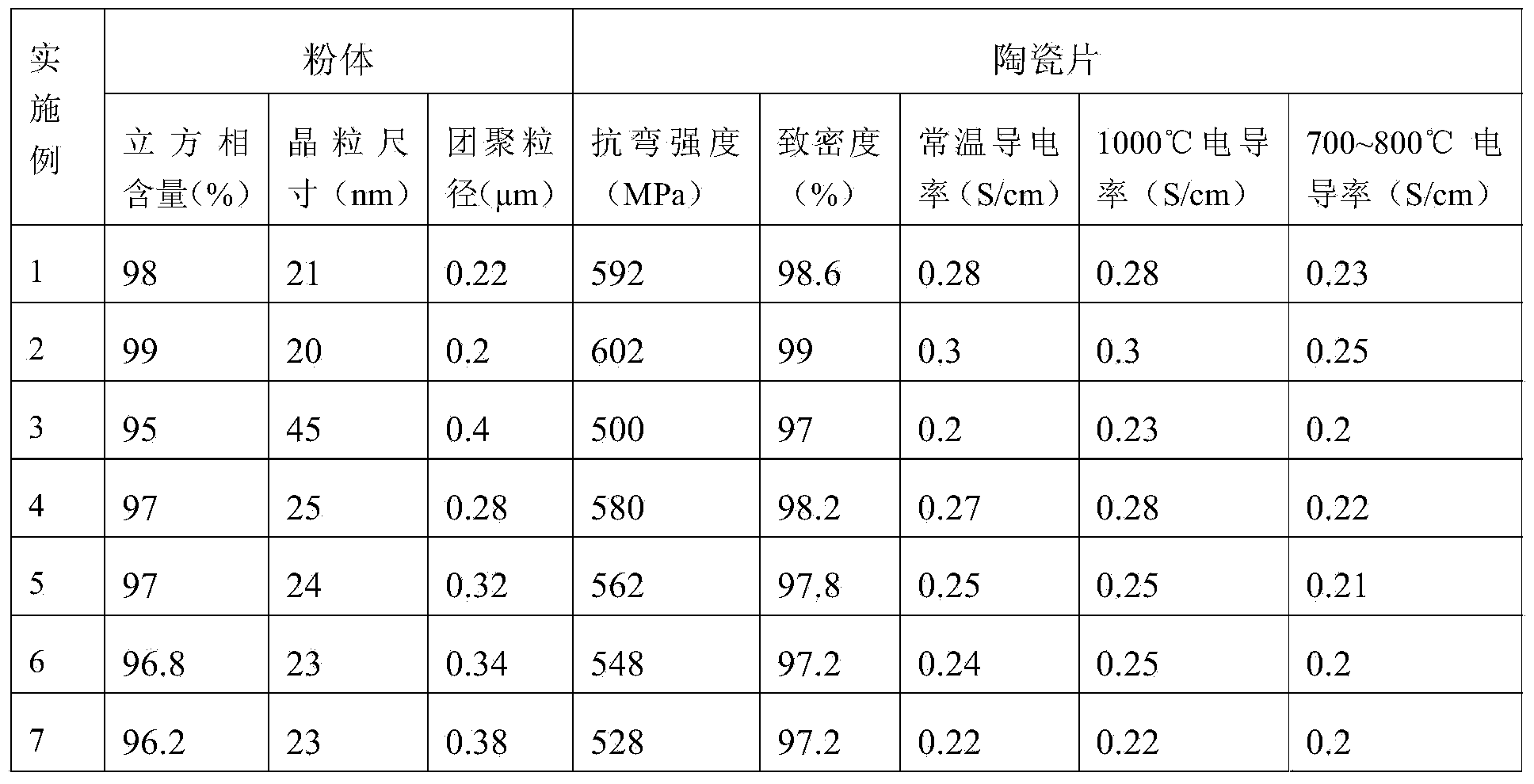

[0034] Simultaneously, the present invention provides a kind of Sc 2 o 3 Stabilized ZrO 2 A method for preparing a base electrolyte powder, the preparation method comprising the following steps: configuring a reaction solution: combining zirconyl nitrate, Sc 2 o 3 , optional CeO 2 and optional auxiliary materials are added to the nitric acid solution, and mixed to obtain the precursor mother liquid nitric acid solution. Co-precipitation treatment: adding the ammonium bicarbonate-ammonia water buffer system solution into the nitric acid solution of the precursor mother liquor, stirring and reacting, and co-precipitating to obtain a colloidal solution of the precursor. Spray treatment: spray the precursor colloidal solution as a spray liquid to form precursor powder. Heat treatment: heat treatment of the precursor powder to obtain the Sc 2 o 3 Stabilized ZrO 2 base electrolyte powder.

[0035] Sc provided by the present invention 2 o 3 Stabilized ZrO 2 The preparatio...

Embodiment 1

[0044] sc 2 o 3 Stabilized ZrO 2 Preparation method of base electrolyte powder:

[0045] (1) Configure the reaction solution: dissolve zirconyl nitrate in water to obtain a zirconyl nitrate solution; 2 o 3 (Feeding amount is Sc 2 o 3 Stabilized ZrO 2 9mol% of the total molar weight of the base electrolyte powder), CeO 2 (Feeding amount is Sc 2 o 3 Stabilized ZrO 2 1wt.% of the total mass of base electrolyte powder) was dissolved in hot nitric acid solution at a temperature of 90°C, heated and stirred to form a nitric acid mixed solution; the nitric acid mixed solution was added to the zirconium oxynitrate solution, and polyethylene glycol 2000 and polyethylene glycol 20000 (the weight ratio of the two is 1:1, and the total amount is 1wt.% of the total weight of the precursor mother liquor nitric acid solution) and (NH 4 ) 2 SO 4 (The dosage is 2% of the molar concentration of the total metal ions in the nitric acid solution of the precursor mother liquor) was adde...

Embodiment 2

[0053] sc 2 o 3 Stabilized ZrO 2 The preparation method of base electrolyte powder: with embodiment 1, wherein, does not add CeO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com