Nickel-based cell anode, its preparation method and nickel-based cell by using anode

A battery positive electrode, nickel-based technology, applied in the field of nickel-based battery positive electrode and its preparation, can solve the problems of high internal resistance of nickel-based battery, uneven dispersion of insoluble calcium salt additives, complicated preparation process, etc. Improved loop performance, simple step effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

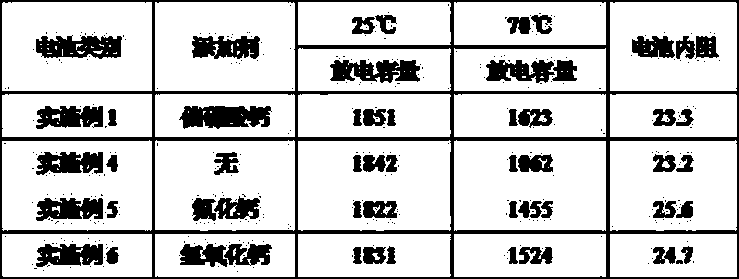

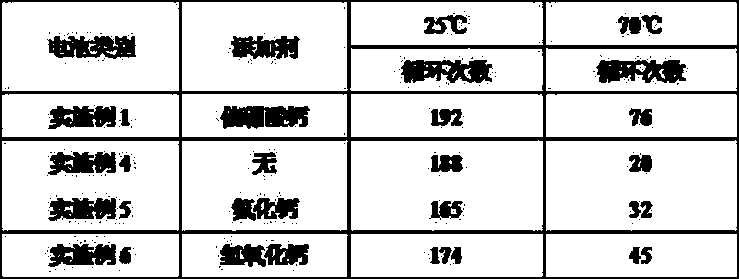

Embodiment 1

[0016] Preparation of positive electrode: (1) Mix 100g of spherical nickel hydroxide, 5g of cobaltous oxide and 5g of T255 nickel powder to make active material mixture; (2) mix 1.0g of calcium metaborate and 2.5g of hydroxypropylmethyl After the cellulose is mixed evenly, add it to 20g of deionized water, and stir to form a uniform aqueous solution; (3) Add the active material mixture prepared in step (1) to the aqueous solution in step (2), and add 1.0g polytetrafluoroethylene The vinyl fluoride emulsion is mixed evenly to make a slurry; (4) A positive electrode product with a length and width of 90mm×42mm is prepared through processes such as pulp drawing, drying, cutting, powder cleaning, and electrode ear welding.

[0017] Preparation of the negative electrode: The hydrogen storage alloy powder is rolled onto the copper grid of the negative electrode substrate using the nickel-metal hydride battery dry negative electrode process, and a layer of polytetrafluoroethylene emul...

Embodiment 2

[0020] Production of the positive electrode: (1) Mix 100g of spherical nickel hydroxide, 0.25g of cobaltous oxide and 0.25g of T255 nickel powder to make an active material mixture; (2) Mix 0.01g of calcium borate and 0.5g of carboxymethyl fiber Mix plain sodium evenly and add to 10g of deionized water, stir to form a uniform aqueous solution; (3) Add the active material mixture prepared in step (1) to the aqueous solution in step (2), and add 0.1g of polytetrafluoroethylene The ethylene emulsion is mixed evenly to make a slurry; (4) A positive electrode product with a length and width of 90mm×42mm is prepared through processes such as pulp drawing, drying, cutting, powder cleaning, and electrode ear welding.

[0021] Preparation of the negative electrode: The hydrogen storage alloy powder is rolled onto the copper grid of the negative electrode substrate using the nickel-metal hydride battery dry negative electrode process, and a layer of polytetrafluoroethylene emulsion is so...

Embodiment 3

[0024]Production of positive electrode: (1) Mix 100 parts of spherical nickel hydroxide, 2 g of cobaltous oxide and 4 g of T255 nickel powder to make active material mixture; (2) Mix 5 g of calcium metaborate and 5 g of hydroxypropyl methylcellulose (3) Add the active material mixture prepared in step (1) to the aqueous solution in step (2), and add 2g of polytetrafluoroethylene emulsion Mix evenly to make a slurry; (4) Prepare a positive electrode product with a length and width of 90mm×42mm through processes such as pulp drawing, drying, cutting, powder cleaning, and electrode ear welding.

[0025] Preparation of the negative electrode: The hydrogen storage alloy powder is rolled onto the copper grid of the negative electrode substrate using the nickel-metal hydride battery dry negative electrode process, and a layer of polytetrafluoroethylene emulsion is soaked on the surface. After drying and rolling, it is cut into pieces. The finished negative electrode with a size of 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com