Self-traveling drilling type coal mining machine with two-way drilling

A self-propelled, shearer technology, applied in the direction of earthwork drilling, propulsion, cutting machinery, etc., can solve the problems of difficult docking of drill pipes, high driving rate of 10,000 tons of coal, pressure drilling and buried drilling tools, etc., to achieve The labor intensity of workers is low, the maintenance equipment is safe and convenient, and the coal quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following embodiments will further describe the present invention in conjunction with the accompanying drawings.

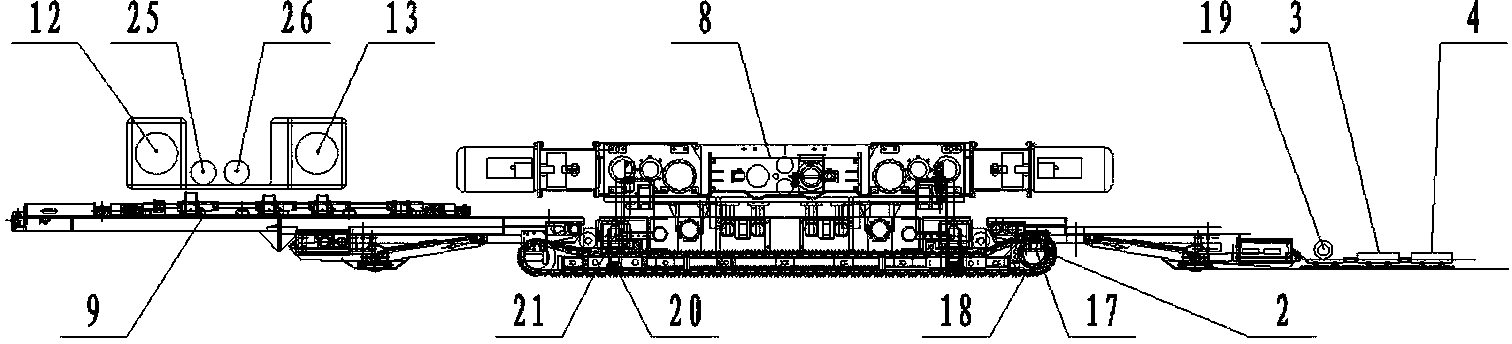

[0032] like figure 1 , figure 2 and image 3 As shown, a self-propelled drilling shearer capable of bidirectional drilling includes a vehicle frame assembly 1, a traveling device 2, an electric control assembly 3, a hydraulic assembly 4, a drilling tool assembly 5, a ventilation device 6, The propulsion arm device 7, the propulsion arm propulsion device 8, the propulsion arm docking and pushing device 9, the vehicle frame assembly 1 includes the traveling device 2, the propulsion arm propulsion device 8, the propulsion arm docking and pushing device 9, the supporting cylinder 16 and the vehicle frame lifting device 22 , the running device 2 includes a hydraulic motor 17 and a crawler belt 18, the frame assembly 1 is connected with the frame support frame 20 on the running device 2 through a coupling fixing device 21, the electric control assembly 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com