Preparation method of polypropylene car bumper

A technology for automobile bumpers and polypropylene, applied to bumpers and other directions, can solve the problems of heat distortion temperature and other performance degradation, high cost, and high rubber consumption, and achieve good overall performance, efficiency improvement, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

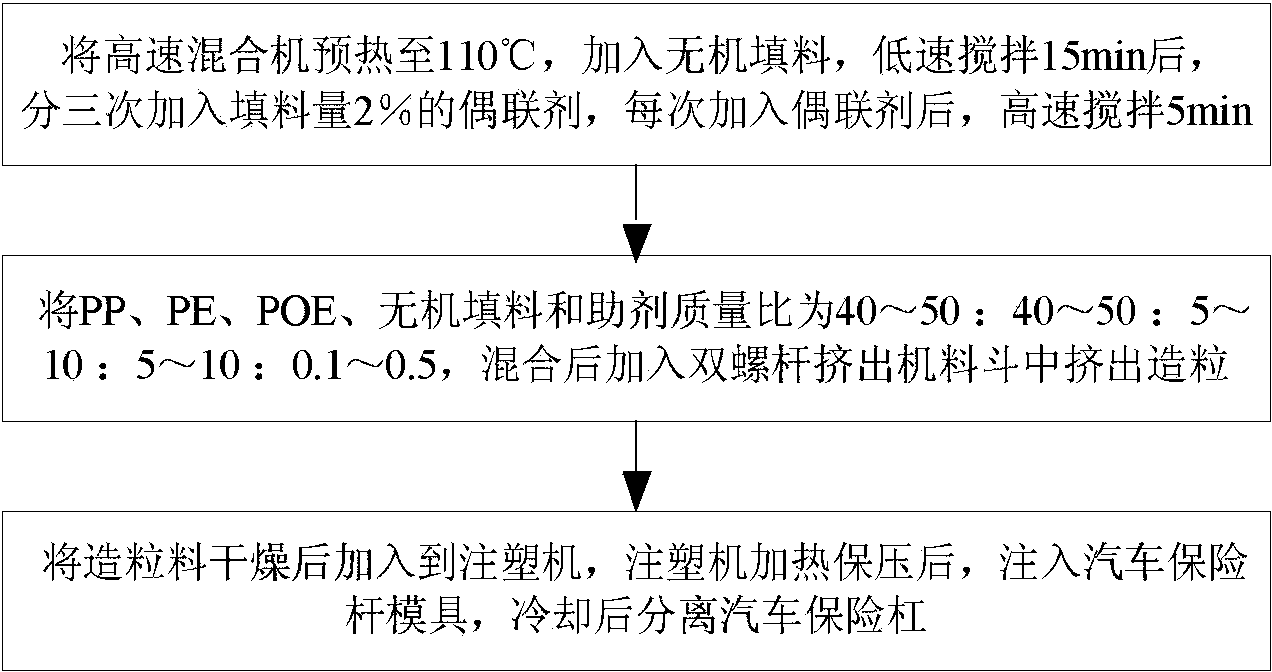

Image

Examples

Embodiment 1

[0024] Preheat the high-speed mixer to 110°C, add talcum powder, stir at a low speed for 15 minutes, then add titanate coupling agent equal to 2% of the talcum powder in three times, and stir at high speed after each addition of titanate coupling agent 5min, then release the talcum powder;

[0025] Mix PP, PE, POE, talcum powder, and additives in a mass ratio of 40:40:5:5:0.1, (wherein the mass ratio of bismaleimide, antioxidant, and light stabilizer in the additives 0.07:0.001:0.03), after mixing, the adding conditions are heating temperature 190℃~220℃, main screw speed 200r / min, feeding screw speed 20r / min, extruding and granulating in the twin-screw extruder hopper;

[0026] Dry the granulated material and add it to the injection molding machine. The temperature of the injection molding machine is 190°C-210°C, the injection and holding pressure is 5Mpa, the pre-molding pressure is 6Mpa, the injection molding and holding pressure time is 20s, and the total molding cycle is 5...

Embodiment 2

[0028] Preheat the high-speed mixer to 110°C, add talcum powder, stir at a low speed for 15 minutes, then add titanate coupling agent equal to 2% of the talcum powder in three times, and stir at high speed after each addition of titanate coupling agent 5min, then release the talcum powder;

[0029] Mix PP, PE, POE, talcum powder and additives at a mass ratio of 45:45:7.5:7.5:0.25, (the mass ratio of bismaleimide, antioxidant, and light stabilizer in the additives 0.175:0.0025:0.0725), after mixing, the adding conditions are heating temperature 190℃~220℃, main screw speed 200r / min, feeding screw speed 20r / min, extruding and granulating in the twin-screw extruder hopper;

[0030] Dry the granulated material and add it to the injection molding machine. The temperature of the injection molding machine is 190°C-210°C, the injection and holding pressure is 5Mpa, the pre-molding pressure is 6Mpa, the injection molding and holding pressure time is 20s, and the total molding cycle is 5...

Embodiment 3

[0032] Preheat the high-speed mixer to 110°C, add talcum powder, stir at a low speed for 15 minutes, then add titanate coupling agent equal to 2% of the talcum powder in three times, and stir at high speed after each addition of titanate coupling agent 5min, then release the talcum powder;

[0033] Mix PP, PE, POE, talcum powder, and additives in a mass ratio of 50:50:10:10:0.5, (wherein the mass ratio of bismaleimide, antioxidant, and light stabilizer in the additives 0.35:0.005:0.15), after mixing, the adding conditions are heating temperature 190℃~220℃, main screw speed 200r / min, feeding screw speed 20r / min, extruding and granulating in twin-screw extruder hopper;

[0034] Dry the granulated material and add it to the injection molding machine. The temperature of the injection molding machine is 190°C-210°C, the injection and holding pressure is 5Mpa, the pre-molding pressure is 6Mpa, the injection molding and holding pressure time is 20s, and the total molding cycle is 55s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com