Method for milling microwave parts with irregular structure through micro-stress

A milling and irregular technology, which is applied in the field of micro-stress milling of microwave parts with irregular structures, can solve the problems of low production efficiency, affecting the edge surface quality, and low surface quality of parts, so as to improve production efficiency and parts yield. , Improve signal transmission performance and ensure the effect of dimensional accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

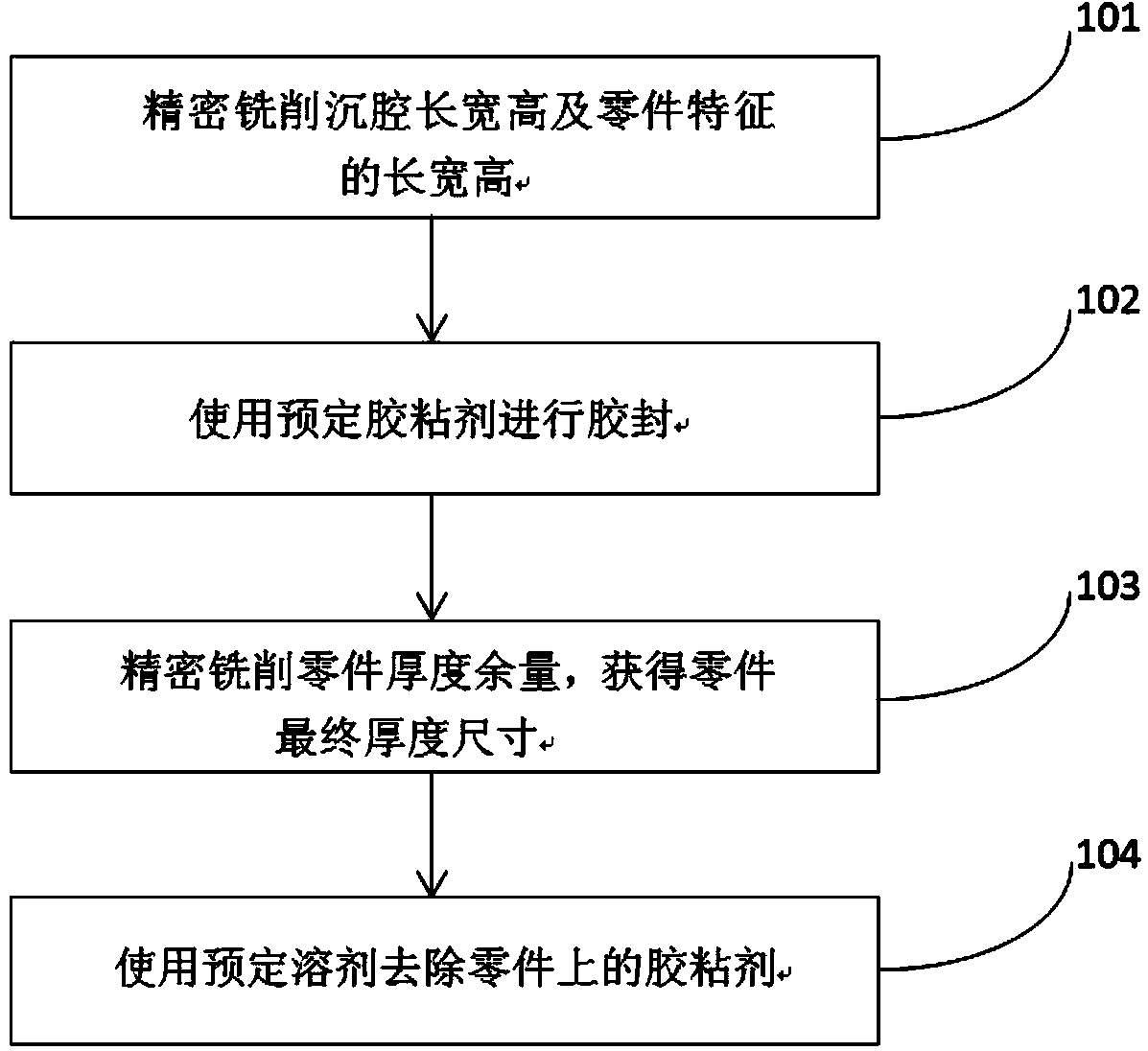

[0036] Such as figure 1 as shown, figure 1 A flow chart of a method for realizing micro-stress milling of irregular structure microwave parts provided by the present invention, the method includes the following steps:

[0037] Step 101: Precisely milling the sink cavity and the feature size of the part (that is, the length, width and height of the precision milling sink cavity and the length, width and height of the part feature;

[0038] Step 102: use a predetermined adhesive to seal;

[0039] Step 103: Precisely milling the thickness allowance of the part to obtain the final thickness dimension of the part;

[0040] Step 104: After the processing is completed, use a predetermined solvent to remove the adhesive on the part.

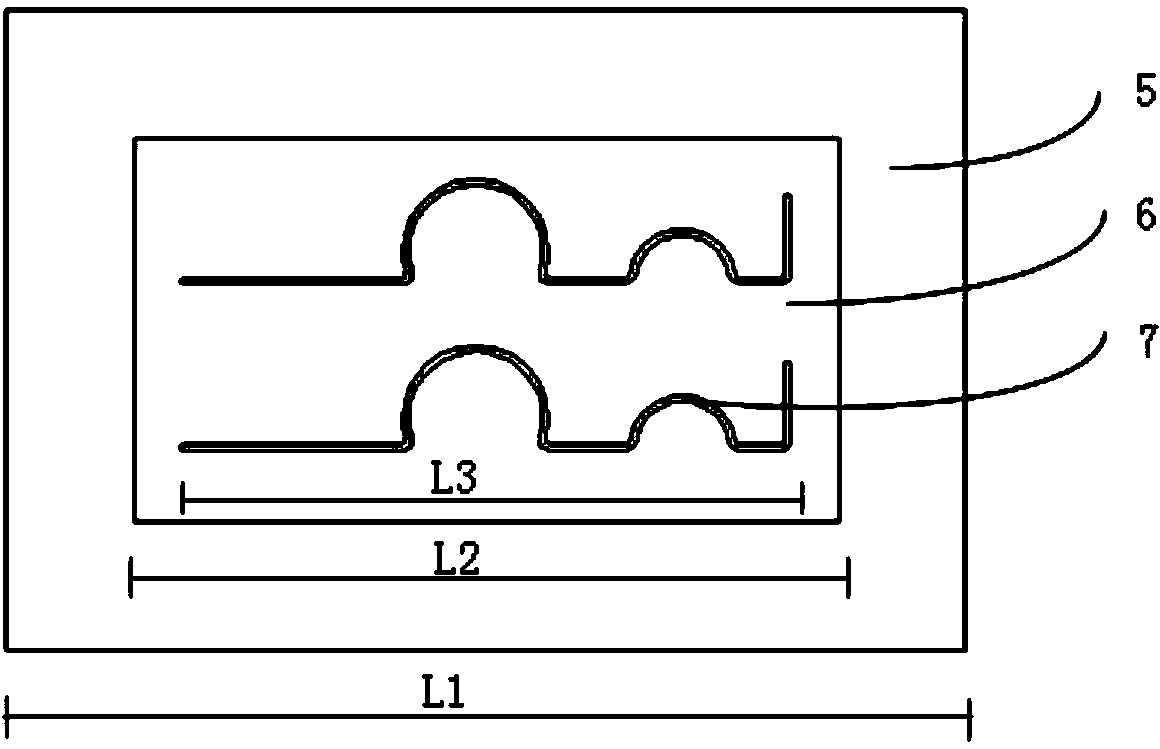

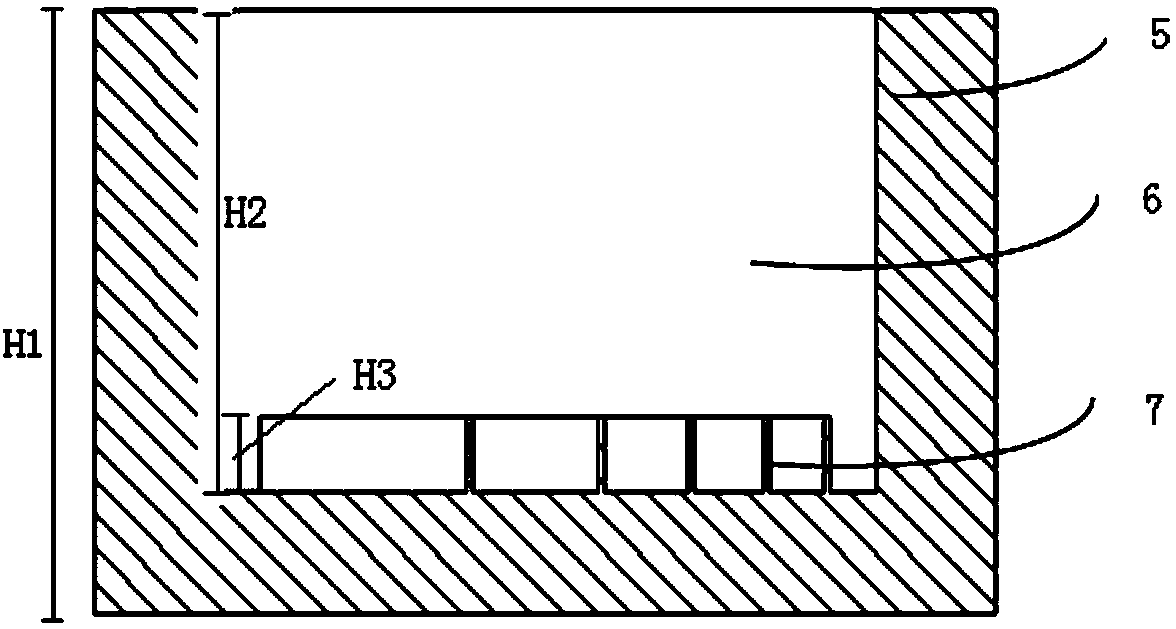

[0041] In the above step 101, the precise milling of the counterbore cavity and the feature size of the part includes: milling a counterbore cavity with a suitable size on the blank, and then milling the feature size of the part. Among them, the size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com