Method for circularly repairing organic polluted soil by cyclodextrin eluting solution

A technology for organic pollution and organic pollutants, which is applied in the restoration of polluted soil and other directions, can solve problems such as secondary pollution, and achieve the effects of no secondary pollution, simple and easy method, and good elution effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

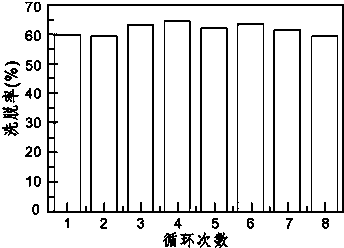

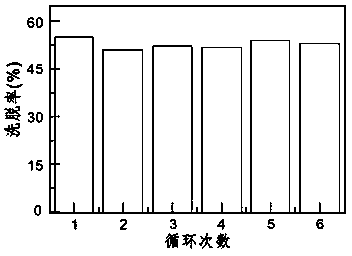

[0023] Add 10 g of organic polluted soil sample A to 500 mL of 100 μmol / L glycine-β-cyclodextrin eluent, place it in a constant temperature shaker at 250 rpm for 5 hours at 25 °C. After the elution was completed, the soil-elution solution mixture was poured into a centrifuge tube, and centrifuged at a speed of 4000rpm for 20min. The supernatant was transferred to a low-pressure mercury lamp direct photodegradation device, and the concentration of 2,4,6-trichlorophenol in the supernatant was measured by high performance liquid chromatography c 0 0.641mg / L, and the elution rate of 2,4,6-trichlorophenol in soil was 80.5%. Adopt high performance liquid chromatography to measure the concentration of 2,4,6-trichlorophenol under different reaction times, measure the concentration c of 2,4,6-trichlorophenol in the supernatant after light 20min t 0.007mg / L, for c 0 1%. Then, 10 g of organic contaminated soil sample A was added to the light-treated supernatant, and elution, centrifug...

Embodiment 2

[0025] In 500mL of 500μmol / L glycine-β-cyclodextrin eluent, add organic contaminated soil sample A to form a soil-elution mixture with an organic contaminated soil content of 40g / L, and place it at a constant temperature at 35°C Shake at 250rpm for 5h on a shaker. After the elution was completed, the soil-elution solution mixture was poured into a centrifuge tube and centrifuged at a speed of 4500rpm for 30min. The supernatant was transferred to a low-pressure mercury lamp direct photodegradation device, and the concentration of 2,4,6-trichlorophenol in the supernatant was measured by high performance liquid chromatography c 0 The elution rate of 2,4,6-trichlorophenol in soil was 1.21mg / L, and the elution rate was 76.0%. Adopt high performance liquid chromatography to measure the concentration of 2,4,6-trichlorophenol in the supernatant under different reaction times, record the concentration c of 2,4,6-trichlorophenol in the supernatant after light 60min t 0.026mg / L, for c ...

Embodiment 3

[0027] In 100mL of 100μmol / L natural β-cyclodextrin eluent, add organic contaminated soil sample B to form a soil-elution mixture with an organic contaminated soil content of 40g / L, and place it at a constant temperature at 15°C Oscillate for 0.5 h at a speed of 250 rpm in a shaker. After the elution was completed, the soil-elution mixture was poured into a centrifuge tube, and centrifuged at a speed of 3000rpm for 30min. Transfer the supernatant to a direct photodegradation device with a low-pressure mercury lamp, and measure the concentration of bisphenol A in the supernatant by high performance liquid chromatography c 0 was 9.48mg / L, and the elution rate of bisphenol A in soil was 50.0%. Adopt high performance liquid chromatography to measure the concentration of bisphenol A in the supernatant under different reaction times, record the concentration c of bisphenol A in the supernatant after light 90min t 0.41mg / L, for c 0 4.3%. Add organic contaminated soil sample B to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com