SCR (selective catalytic reduction) catalyst for denitrating low-temperature smoke of cement kiln and preparation method thereof

An SCR catalyst, low temperature flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

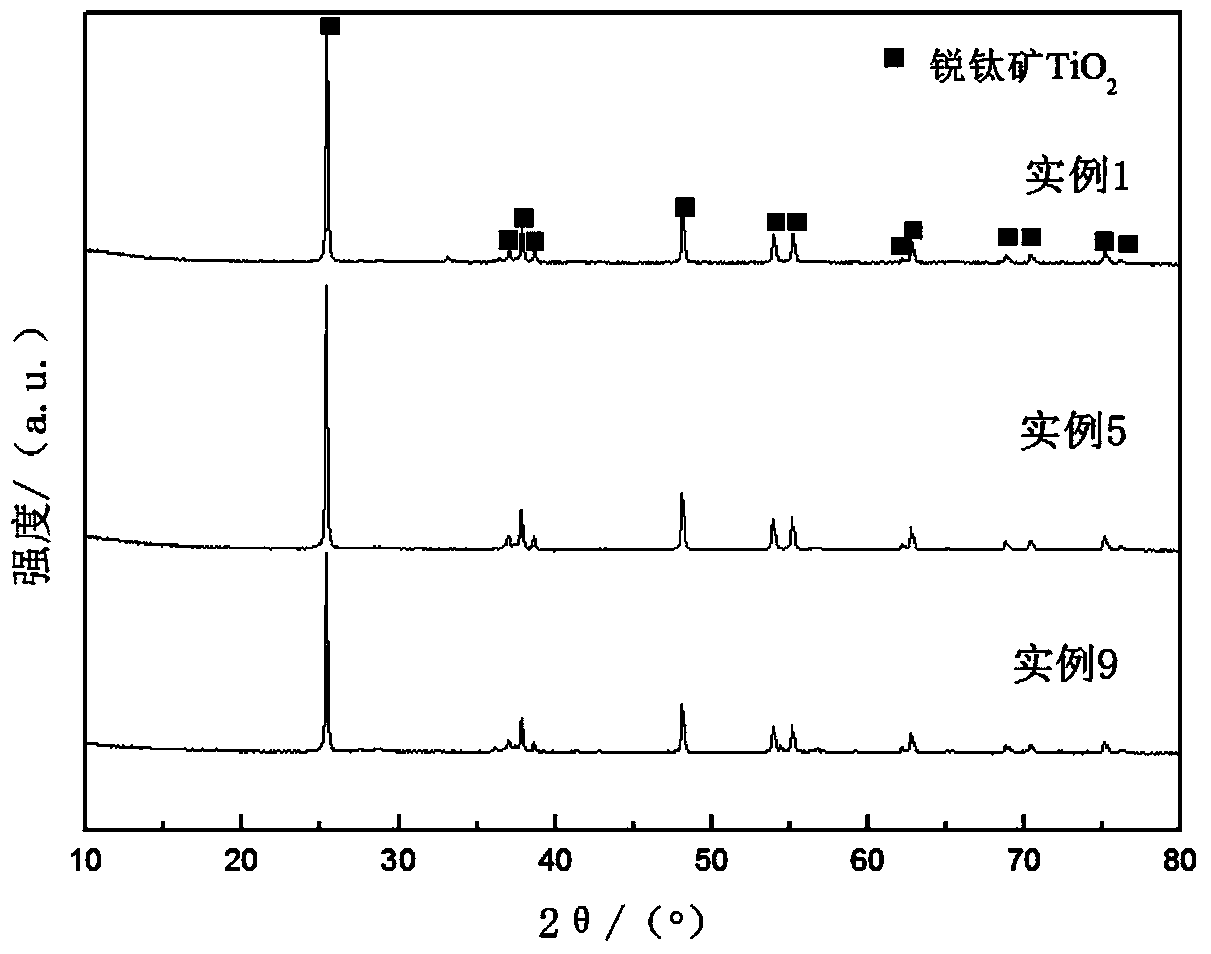

[0058] Embodiment 1, preparation SCR catalyst

[0059] The preparation of SCR catalyst comprises the following steps:

[0060] 1. Preparation of carrier

[0061] will analyze pure titanium dioxide (TiO 2 ) powder with H 2 O, CMC (hydroxymethyl cellulose), MEA (monoethanolamine), etc. are mixed according to the mass ratio of 100:10:1:1, formed into agglomerates, extruded to obtain a strip carrier, and dried in a 60°C drying oven Dry it, and then place it in a muffle furnace for calcination at 1000°C (500-1200°C is acceptable) for 6h (2-10h is acceptable) to obtain a carrier.

[0062] 2. Loading of active components

[0063]1) According to step 1, select a strip-shaped carrier with a certain mass and uniform size, the percentage of the active component in the overall mass of the catalyst including the carrier is 15wt%, and the manganese (Mn) element accounts for the moles of the total elements of the active component Ratio of 0.75 (75% by mole percent), calculate the mass o...

Embodiment 2

[0065] Embodiment 2, preparation SCR catalyst

[0066] Include the following steps:

[0067] 1. Preparation of carrier

[0068] will analyze pure titanium dioxide (TiO 2 ) powder and silicon dioxide (SiO 2 ) powder with H 2 O, CMC (hydroxymethyl cellulose), MEA (monoethanolamine), etc. are mixed according to the mass ratio of 50:50:10:1:1, formed into agglomerates, extruded to obtain a strip carrier, and dried in a 60°C drying oven Drying in the oven, and then placed in a muffle furnace for calcination at 1000°C (500-1200°C is acceptable) for 4h (2-10h is acceptable) to obtain the carrier.

[0069] 2. Loading of active components

[0070] Same as Example 1.

Embodiment 3

[0071] Embodiment 3, preparation SCR catalyst

[0072] Include the following steps:

[0073] 1. Preparation of carrier

[0074] will analyze pure titanium dioxide (TiO 2 ) powder and aluminum trioxide (Al 2 o 3 ) powder with H 2 O, CMC (hydroxymethyl cellulose), MEA (monoethanolamine), etc. are mixed according to the mass ratio of 50:50:10:1:1, agglomerated, extruded to obtain a honeycomb carrier, and dried in a 60°C drying oven Dry it in the oven, and then place it in a muffle furnace for calcination at 1000°C for 6 hours to obtain a carrier.

[0075] 2. Loading of active components

[0076] Same as Example 1.

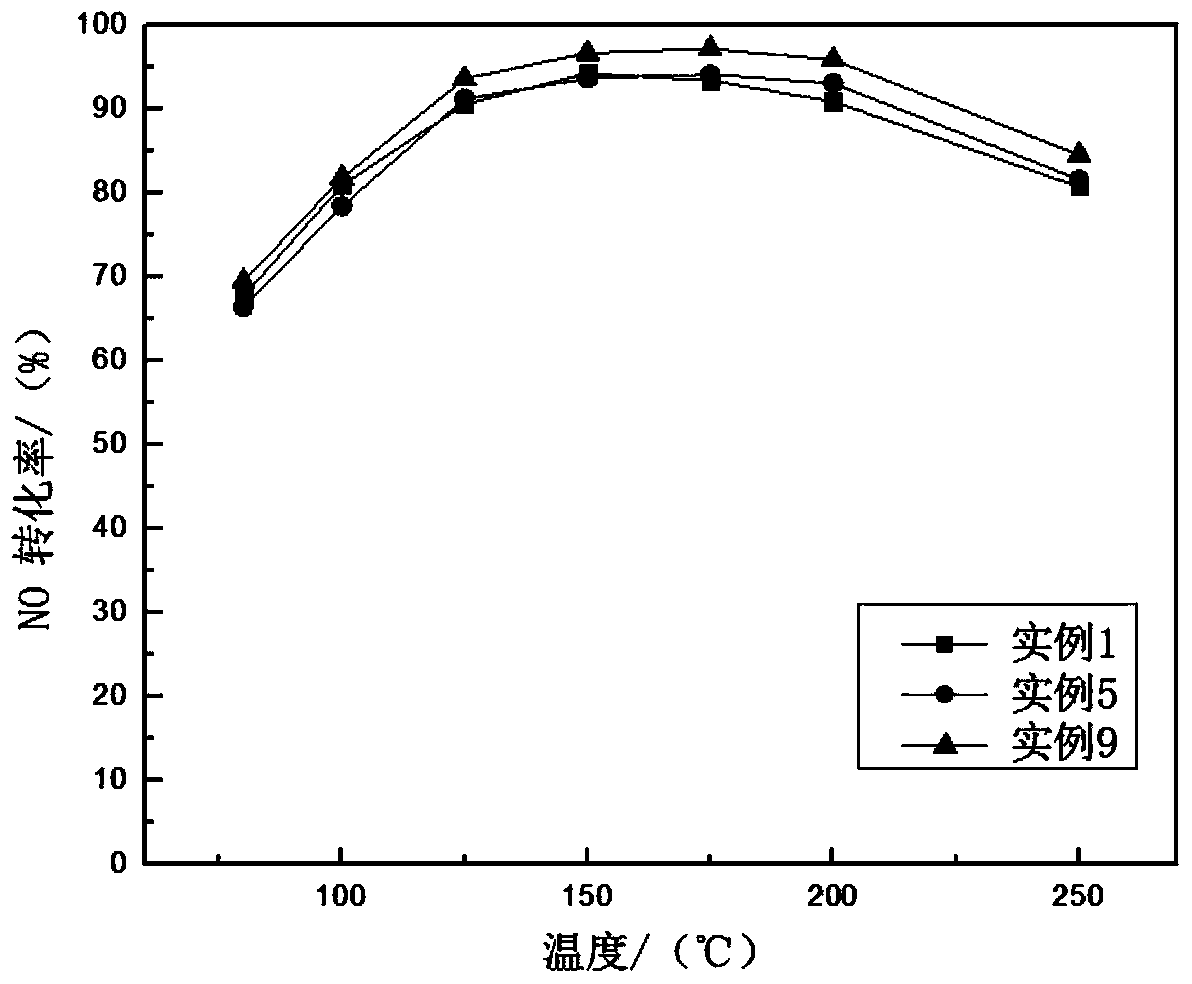

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com