Palladium nanoparticle modified carbon nanotube composite material as well as preparation method and application thereof

A technology of carbon nanotubes and composite materials, applied in the field of nanomaterials, to achieve the effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a carbon nanotube composite material modified with palladium nanoparticles.

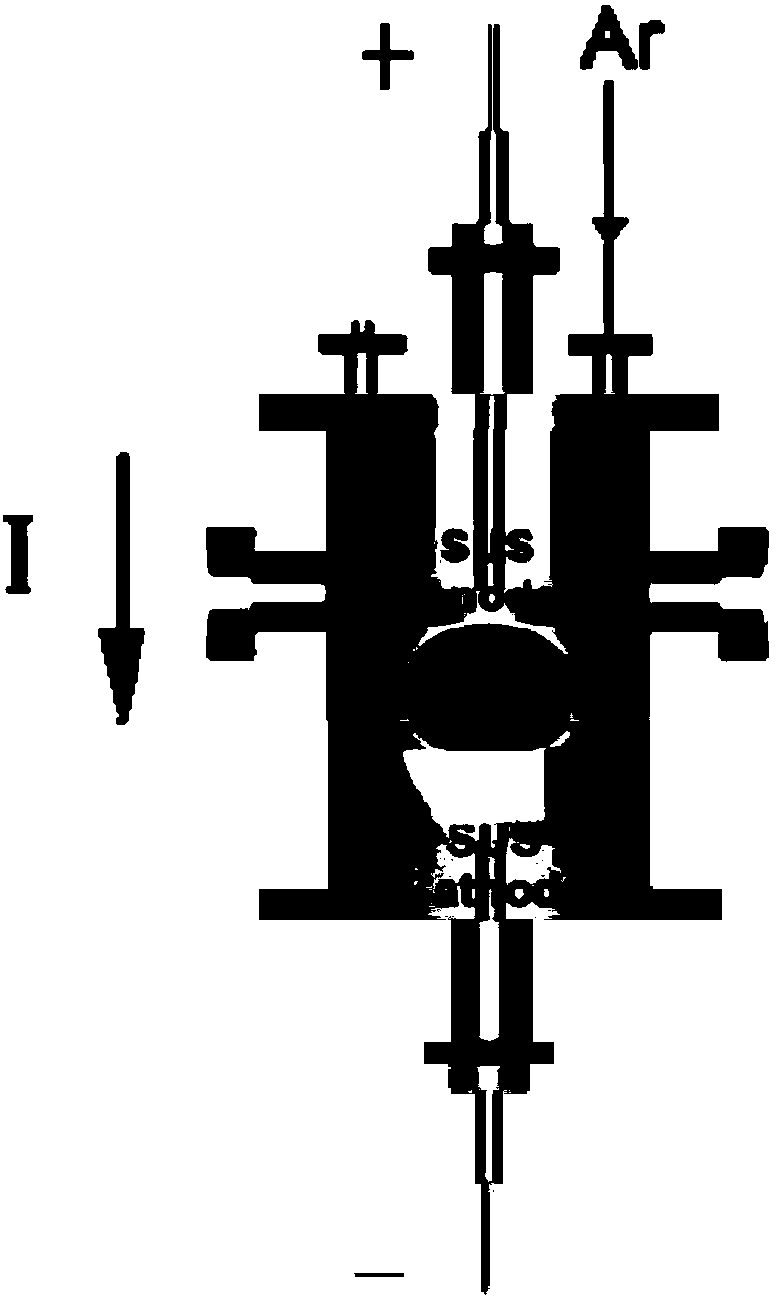

[0041] The device used to prepare the carbon nanotube composite material modified with palladium nanoparticles is a gas-liquid glow plasma reaction device, such as figure 1 Said, the gas-liquid glow plasma reaction equipment is a stainless steel furnace. The stainless steel furnace is a cylinder with an inner diameter of 70mm and has 4 visible glass windows. The stainless steel furnace has a stainless steel plate located in the upper position of the furnace. The anode and the cathode of a stainless steel vessel containing a mixture of carbon nanotubes, palladium acetate, and 1-butyl-3-methylimidazole tetrafluoroborate located at the lower position in the furnace, the distance between the anode and the cathode is 2-6mm, the cathode is connected to a DC power supply (KIKUSUI PMC500V-0.1A).

[0042] The preparation method of the carbon nanotube composite material modified by p...

Embodiment 2

[0048] This embodiment provides a carbon nanotube composite material modified with palladium nanoparticles. The device used to prepare the carbon nanotube composite material modified with palladium nanoparticles is the device described in Example 1.

[0049] The preparation method of the palladium nanoparticle-modified carbon nanotube composite material is basically the same as the preparation method in Example 1, except that the amounts of carbon nanotubes and palladium acetate are 50 mg and 2.2 mg, respectively (carbon nanotubes and Pd The mass ratio is 49:1).

[0050] The prepared carbon nanotube composite material modified with palladium nanoparticles was analyzed by scanning electron microscopy, and the resulting scanning electron microscopy picture is as follows: Image 6 Shown. by Image 6 It can be seen that the particle size of the palladium nanoparticles is 4-6 nm, and the particle size of the palladium nanoparticles is small and the dispersion is uniform.

Embodiment 3

[0052] This embodiment provides a carbon nanotube composite material modified with palladium nanoparticles. The device used to prepare the carbon nanotube composite material modified with palladium nanoparticles is the device described in Example 1.

[0053] The preparation method of the carbon nanotube composite material modified by palladium nanoparticles is basically the same as the preparation method in Example 1, except that the amounts of carbon nanotubes and palladium acetate are 50 mg and 5.6 mg, respectively (carbon nanotubes and Pd The mass ratio is 19:1).

[0054] The prepared palladium nanoparticle-modified carbon nanotube composite material was analyzed by scanning electron microscopy, and the resulting scanning electron microscopy picture is as follows Figure 7 Shown. by Figure 7 It can be seen that the particle size of the palladium nanoparticles is 5-7 nm, and the particle size of the palladium nanoparticles is small and the dispersion is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com