Active antistatic agent and ultraviolet light polymerization antistatic coating thereof

A technology of antistatic agent and ultraviolet light, which is applied in the direction of conductive coating, coating, organic chemistry, etc., can solve the problem of poor compatibility between antistatic agent and matrix resin, poor antistatic performance of antistatic agent, antistatic performance Non-durable and other problems, to achieve long-lasting excellent antistatic performance, solve the effect of non-durable antistatic effect, and good uniform coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

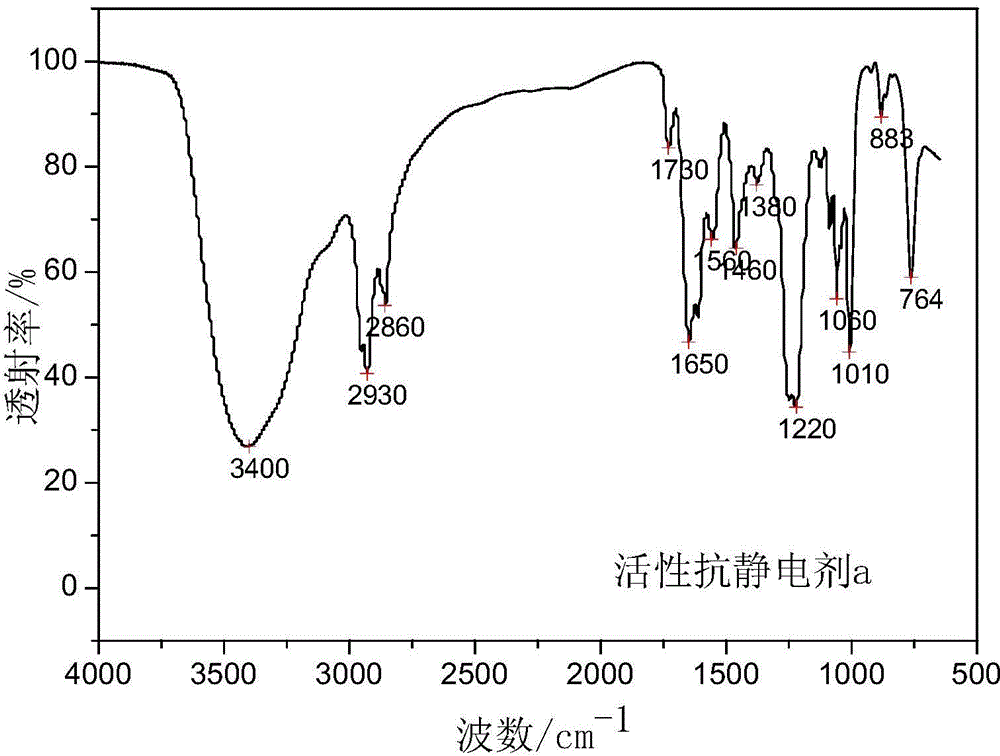

[0040] Embodiment 1: Preparation of UV curing antistatic agent a

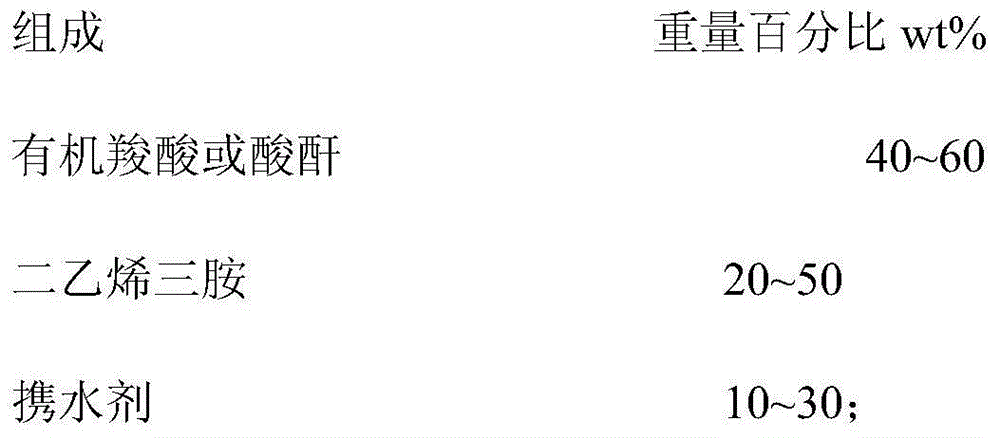

[0041] (1) Synthesis of alkylamide imidazoline: First, add 14.4 g of acrylic acid to a four-necked flask equipped with a water separator, reflux condenser, thermometer and stirrer, and heat up to 130°C; then use a constant pressure dropping funnel to slowly Add 12.4g of diethylenetriamine dropwise, during the dropwise addition process, exothermic heat can be clearly seen, and at the same time, the color of the reactant gradually deepens, and the temperature continues to rise to 160°C after the dropwise addition; then add 8.0g of water-carrying agent xylene, and react for 3 hours, The generated water and xylene are azeotropically separated by a water separator. Finally, continue to raise the temperature to 200°C to carry out the cyclization reaction, and finish the reaction after dehydration to generate an imidazoline intermediate.

[0042] (2) Introduction of active groups: Cool the imidazoline intermediate pr...

Embodiment 2

[0046] Embodiment 2: Preparation of UV curing antistatic agent b

[0047] (1) Preparation of imidazoline intermediate: first add 28.24 g of maleic anhydride to a four-necked flask equipped with a water separator, reflux condenser, thermometer and stirrer, and raise the temperature to 130°C; Slowly add 12.4g of diethylenetriamine into the liquid funnel dropwise, heat can be clearly seen during the dropping process, and at the same time the color of the reactant gradually deepens, and the temperature continues to rise to 160°C after the drop is complete; then add a water-carrying agent with a mass fraction of 35% Xylene, reacted for 3 hours, the generated water and xylene were azeotropically separated through the water separator, and finally continued to heat up to 210°C to carry out the cyclization reaction.

[0048] (2) Introduction of active groups: Cool the above-synthesized imidazoline intermediate to 85°C, and perform rotary distillation under vacuum conditions to remove u...

Embodiment 3

[0052] Embodiment 3: the preparation of UV curing antistatic coating a

[0053] Prepare UV curing antistatic coating with Taiwan Changxing 6210, pentaerythritol triacrylate PETA, 1,6-hexanediol diacrylate, 1173 photoinitiator, and ultraviolet light curing antistatic agent a according to a certain ratio, and use a wire bar to coat the board , cured under UV light. The formula of UV curing antistatic coating a is shown in Table 3.

[0054] Table 3 UV curing antistatic coating formula

[0055]

[0056]

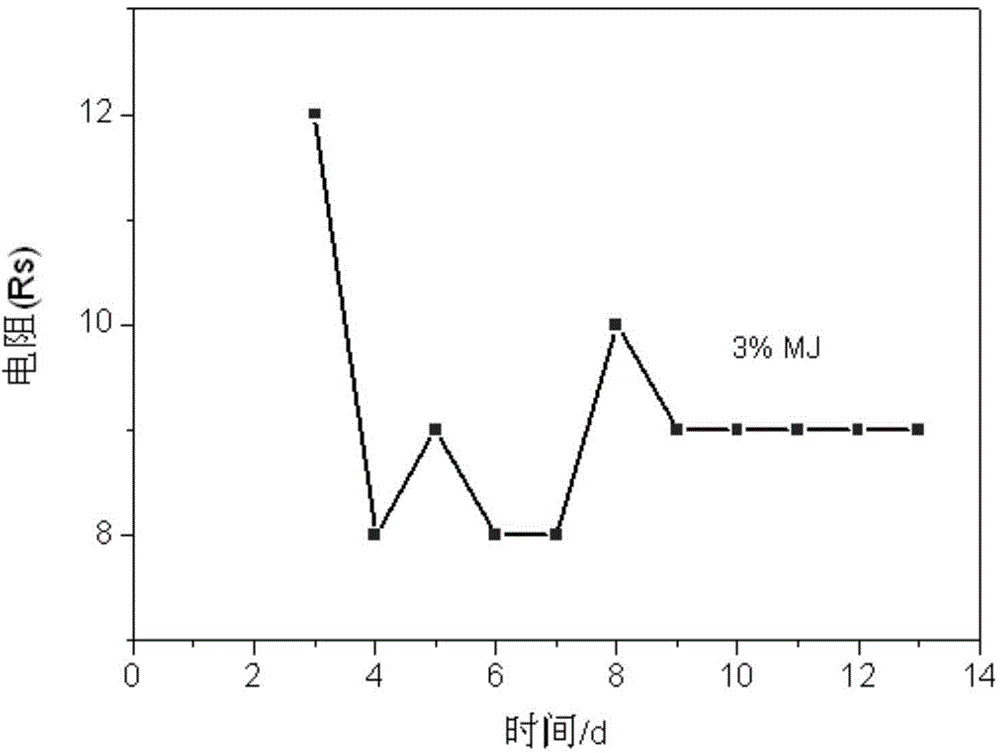

[0057] Embodiment 3 makes UV photocuring antistatic coating film performance as shown in table 4, and coating film surface resistance changes with time as follows figure 2 .

[0058] The UV photocuring antistatic coating film performance that table 4 embodiment 3 prepares

[0059] Test items

[0060] Depend on figure 2 It can be seen that the surface resistance of the UV-cured antistatic coating film changes with time: when the coating film is just cured, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com