Biochemical pretreatment method of coal chemical industry wastewater

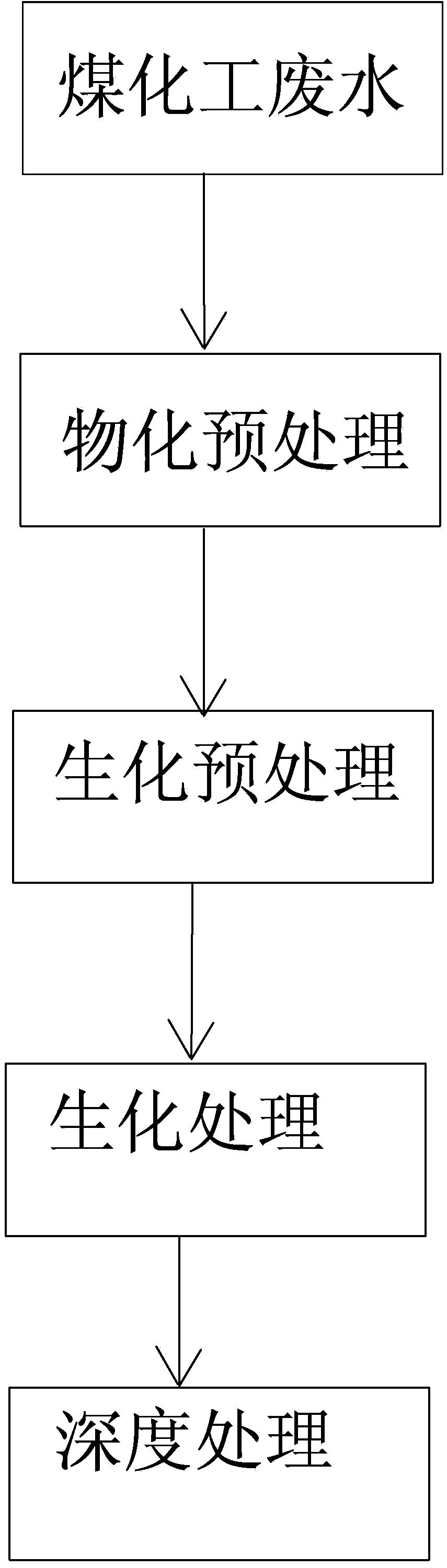

A technology for coal chemical wastewater and biochemical treatment, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem that the ratio of biochemical oxygen demand to chemical oxygen demand in coal chemical wastewater is small , Poor biodegradability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention solves the problem that the ratio of biochemical oxygen demand to chemical oxygen demand of coal chemical industry wastewater is small and the biodegradability is poor. Under the irradiation and catalysis of ultraviolet rays, hydrogen peroxide generates hydroxyl groups with high reactivity under the action of divalent iron salt. Free radicals (·OH), and the enhanced performance of hydroxyl radicals (·OH) are very effective in degrading macromolecular refractory organics in coal chemical wastewater. Therefore, the ratio of biochemical oxygen demand to chemical oxygen demand of coal chemical industry wastewater is improved, and the biodegradability of wastewater is improved.

[0018] The technical solution adopted by the present invention to realize the object of the invention is that the method may further comprise the steps:

[0019] Step 1. Inject the coal chemical wastewater into the reaction pool, and use a radiation intensity of 0.01W / m 2 Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com