A kind of preparation method of magnetic mesoporous free radical controllable polymeric ion-imprinted adsorbent

A technology of ion imprinting and free radicals, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems that have not been reported yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

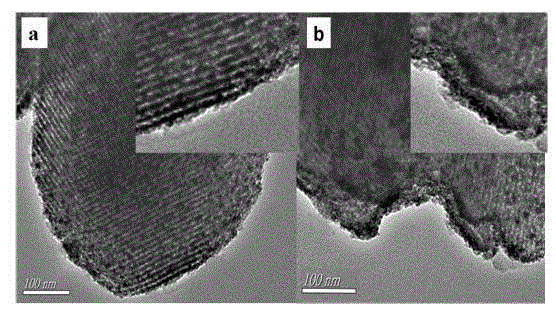

Image

Examples

Embodiment 1

[0032] (1) Synthesis of magnetic mesoporous SBA-15 (Fe 3 o 4 SBA-15)

[0033] Weigh 0.1gFe(NO 3 ) 3 9H 2 Dissolve O in 5mL of methanol, continue to add 0.1g of SBA-15, stir well until the mixture is uniform, and then dry it in an oven at 80°C. The solid obtained after drying was fully ground into powder, exposed to acetic acid vapor at 80°C for 1 h, and then dried in the open at 80°C to remove physically adsorbed acetic acid molecules. Finally, put the dried orange-yellow powder into the tube furnace, N 2 Under protection, the temperature was programmed to rise to 400°C at 5°C / min and kept for 20 minutes to obtain Fe-doped 3 o 4 particles of magnetic mesoporous SBA-15 (Fe 3 o 4 SBA-15).

[0034] (2) Benzylated Fe on the surface 3 o 4 Preparation of SBA-15 (Fe 3 o 4 SBA-15-Cl)

[0035] Get the 0.1gFe synthesized in the above-mentioned steps (1) 3 o 4 Disperse SBA-15 in 10 mL of anhydrous toluene, continue to add 0.1 mL of 4-chloromethyl-phenyltrimethoxysilane, ...

Embodiment 2

[0046] (1) Synthesis of magnetic mesoporous SBA-15 (Fe 3 o 4 SBA-15)

[0047] Weigh 0.2gFe(NO 3 ) 3 9H 2 Dissolve O in 5mL of methanol, continue to add 0.1g of SBA-15, stir well until the mixture is uniform, and then dry it in an oven at 80°C. The solid obtained after drying was fully ground into powder, exposed to acetic acid vapor at 80°C for 1 h, and then dried in the open at 80°C to remove physically adsorbed acetic acid molecules. Finally, put the dried orange-yellow powder into the tube furnace, N 2 Under protection, the temperature was programmed to rise to 400°C at 5°C / min and kept for 20 minutes to obtain Fe-doped 3 o 4 particles of magnetic mesoporous SBA-15 (Fe 3 o 4 SBA-15).

[0048] (2) Benzylated Fe on the surface 3 o 4 Preparation of SBA-15 (Fe 3 o 4 SBA-15-Cl)

[0049] Get the 0.3gFe synthesized in the above-mentioned steps (1) 3 o 4 Disperse SBA-15 in 15 mL of anhydrous toluene, continue to add 0.3 mL of 4-chloromethyl-phenyltrimethoxysilane, ...

Embodiment 3

[0060] (1) Synthesis of magnetic mesoporous SBA-15 (Fe 3 o 4 SBA-15)

[0061] Weigh 0.4gFe(NO 3 ) 3 9H 2 Dissolve O in 5mL of methanol, continue to add 0.1g of SBA-15, stir well until the mixture is uniform, and then dry it in an oven at 80°C. The solid obtained after drying was fully ground into powder, exposed to acetic acid vapor at 80° C. for 1 h, and then dried in the open at 80° C. to remove physically adsorbed acetic acid molecules. Finally, put the dried orange-yellow powder into the tube furnace, N 2 Under protection, the temperature was programmed to rise to 400°C at 5°C / min and kept for 20 minutes to obtain Fe-doped 3 o 4 particles of magnetic mesoporous SBA-15 (Fe 3 o 4SBA-15).

[0062] (2) Benzylated Fe on the surface 3 o 4 Preparation of SBA-15 (Fe 3 o 4 SBA-15-Cl)

[0063] Get the 0.7gFe synthesized in the above-mentioned steps (1) 3 o 4 Disperse SBA-15 in 25mL of anhydrous toluene, continue to add 0.625mL of 4-chloromethyl-phenyltrimethoxysilan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com