Solder powder, and solder paste using solder powder

A technology of solder powder and solder, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of time-consuming, poor yield, poor wettability, etc., and achieve easy control, fast melting, and wettability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

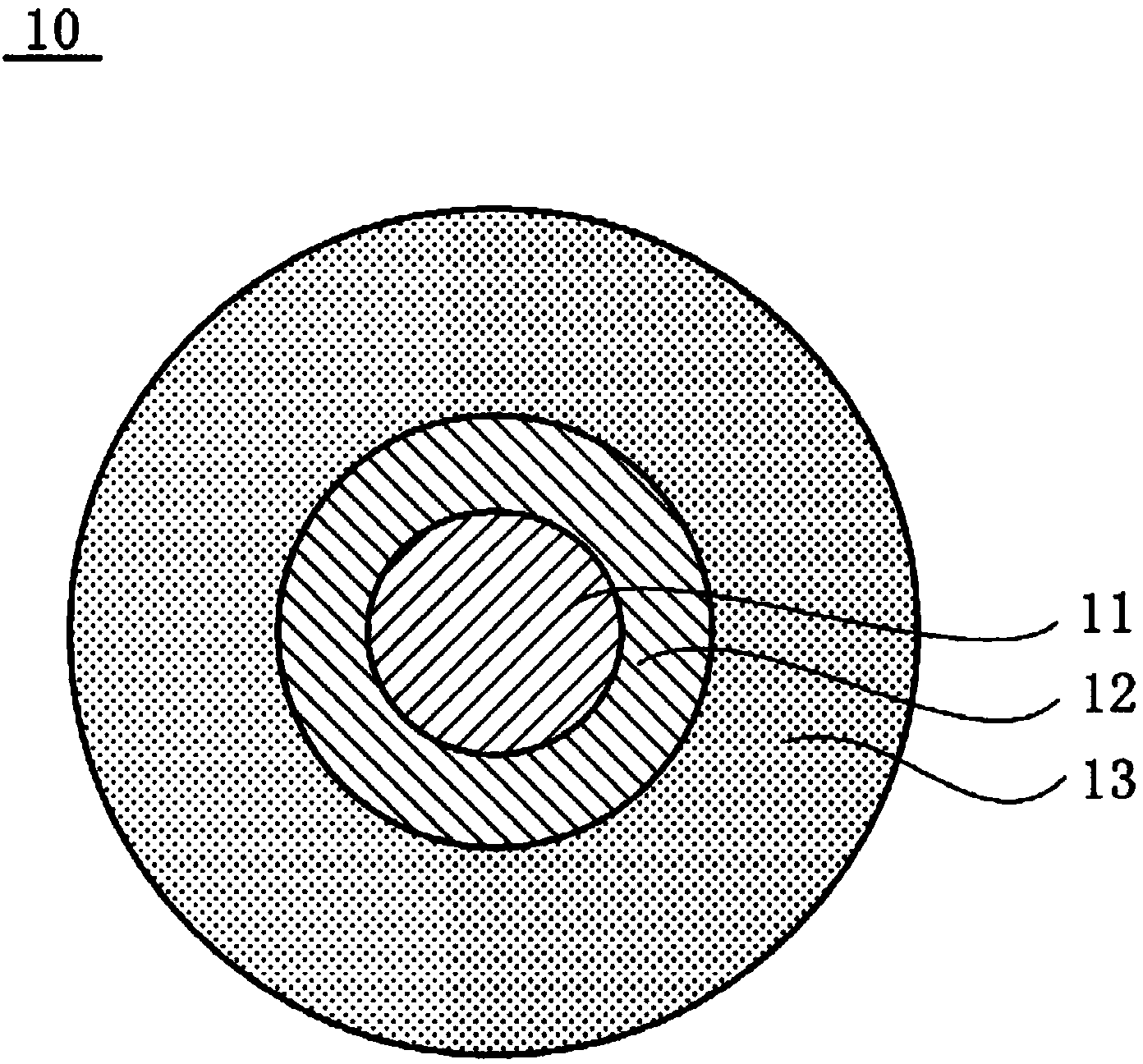

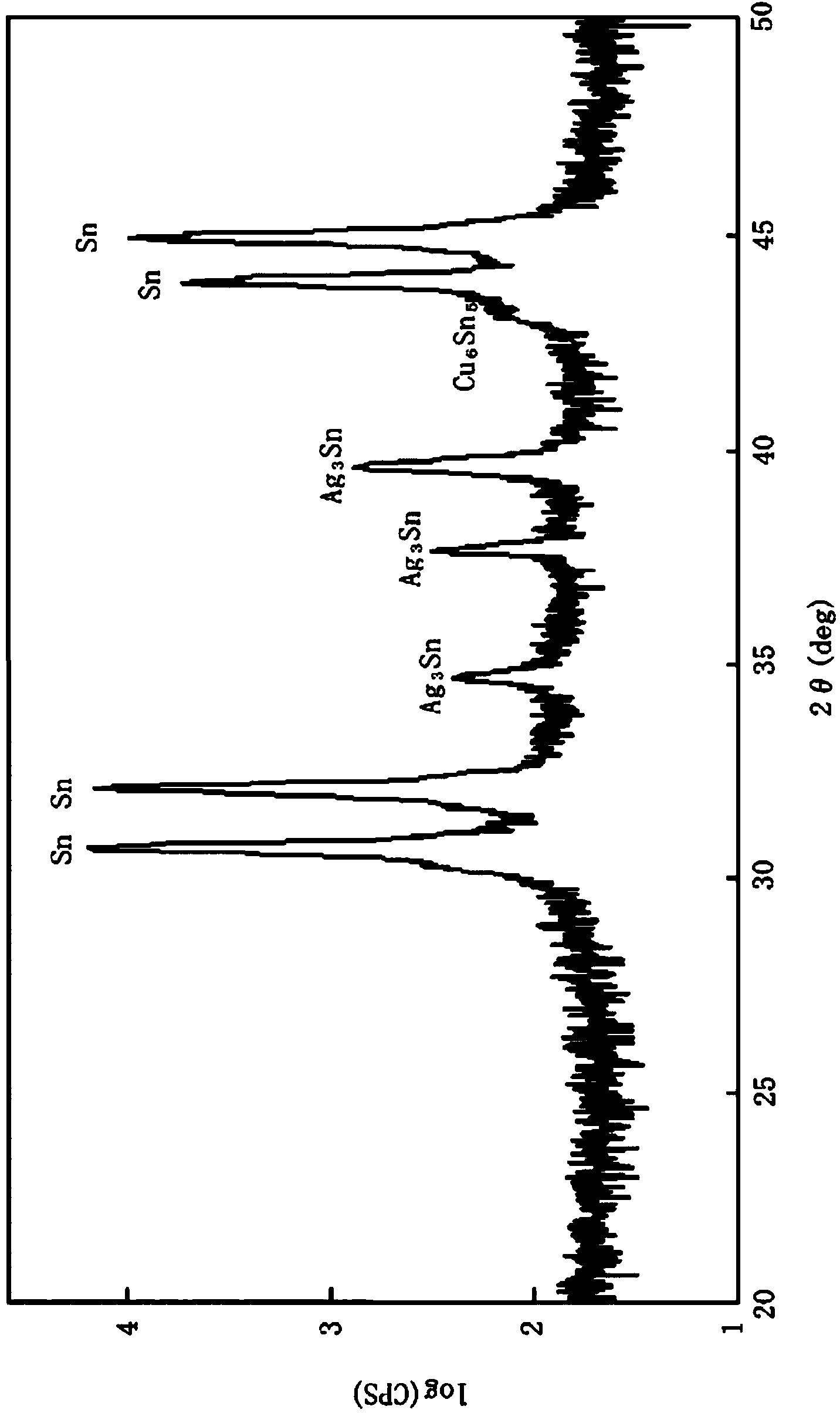

[0051] First, add copper(II) sulfate 2.54×10 to 50mL of water -4 mol, silver sulfate (I) 4.48×10 -4 mol, tin(II) sulfate 2.62×10 -2 mol, stirred with a stirrer at a speed of 300 rpm for 5 minutes to prepare a solution. After adjusting the pH of the solution to 0.5 with sulfuric acid, 0.5 g of polyvinyl alcohol 500 (polyvinyl alcohol having an average molecular weight of 500) was added as a dispersant, and stirred at 300 rpm for 10 minutes. Then, in this solution, add 50mL of 1.58mol / L divalent chromium ion aqueous solution that pH is adjusted to 0.5 with the addition speed of 50mL / sec, stir with the rotating speed of 500rpm for 10 minutes and reduce each metal ion, obtain in solution A dispersion in which metal powder is dispersed. After the dispersion was allowed to stand for 60 minutes to precipitate the generated metal powder, the supernatant was removed, and 100 mL of water was added thereto, followed by stirring at 300 rpm for 10 minutes. This operation was repeated 4 ...

Embodiment 2

[0054] First, add copper(II) sulfate 2.56×10 to 50mL of water -4 mol, silver sulfate (I) 6.04×10 -4 mol, tin(II) sulfate 2.62×10 -2 mol, stirred with a stirrer at a speed of 300 rpm for 5 minutes to prepare a solution. After adjusting the pH of the solution to 0.5 with sulfuric acid, 0.5 g of polyvinyl alcohol 500 was added as a dispersant, and stirred at 300 rpm for 10 minutes. Then, in this solution, add 50mL of 1.58mol / L divalent chromium ion aqueous solution that pH is adjusted to 0.5 with the addition speed of 50mL / sec, stir with the rotating speed of 500rpm for 10 minutes and reduce each metal ion, obtain in solution A dispersion in which metal powder is dispersed. After the dispersion was allowed to stand for 60 minutes to precipitate the generated metal powder, the supernatant was removed, and 100 mL of water was added thereto, followed by stirring at 300 rpm for 10 minutes. This operation was repeated 4 times for washing.

[0055] Thereafter, 100 mL of ethylene gl...

Embodiment 3

[0057] First, add copper(II) sulfate 9.86×10 to 50mL of water -5 mol, silver sulfate (I) 7.26×10 -5 mol, tin(II) sulfate 2.62×10 -2 mol, stirred with a stirrer at a speed of 300 rpm for 5 minutes to prepare a solution. After adjusting the pH of the solution to 0.5 with sulfuric acid, 0.5 g of polyvinyl alcohol 500 was added as a dispersant, and stirred at 300 rpm for 10 minutes. Then, in this solution, add 50mL of 1.58mol / L divalent chromium ion aqueous solution that pH is adjusted to 0.5 with the addition speed of 50mL / sec, stir with the rotating speed of 500rpm for 10 minutes and reduce each metal ion, obtain in solution A dispersion in which metal powder is dispersed. After the dispersion was allowed to stand for 60 minutes to precipitate the generated metal powder, the supernatant was removed, and 100 mL of water was added thereto, followed by stirring at 300 rpm for 10 minutes. This operation was repeated 4 times for washing.

[0058] Thereafter, 100 mL of ethylene gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com