Neodymium iron boron magnetic material with excellent magnetic performance

A magnetic material, neodymium iron boron technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems affecting the number of main phases of ingots, insufficient performance of neodymium iron boron magnets, and adverse effects of processing technology. Achieve the effects of magnet performance and coercive force performance improvement, low final oxygen content, and avoid performance damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

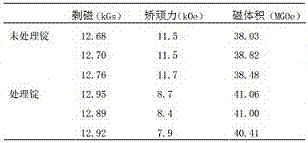

Embodiment 1

[0069] A neodymium-iron-boron magnetic material with excellent magnet performance, which is formed by mixing a main phase alloy and an auxiliary phase alloy; the main phase alloy is configured by weight percentage of the following raw materials: 64.5% iron, 1.2% boron, Neodymium 34.1%, niobium 0.1%, aluminum 0.1%; auxiliary phase alloy is prepared from the following raw materials by weight percentage: iron 53.8%, boron 1.2%, neodymium 19.5%, praseodymium 14.3%, dysprosium 10.2%, copper 1.0%.

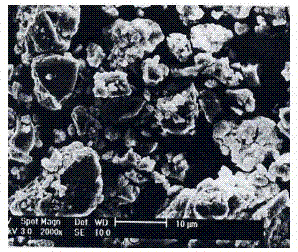

[0070] In the above scheme, the niobium in the main phase alloy can make the crystal grains of the magnet uniform and increase the density of the magnet, so a small amount of niobium added can obviously refine the grains of the alloy, thereby increasing the remanence and magnetic energy product of the magnet; and Aluminum can improve the wettability of the liquid phase and the main phase during the sintering process, make the grain surface smoother, and refine the grains of the main phase...

Embodiment 2

[0128] A neodymium-iron-boron magnetic material with excellent magnet properties, which is formed by mixing a main phase alloy and an auxiliary phase alloy; the main phase alloy is configured by weight percentage of the following raw materials: 68.2% iron, 1.2% boron, Neodymium 30.2%, niobium 0.2%, aluminum 0.2%; auxiliary phase alloy is prepared by the following raw materials by weight percentage: iron 54.2%, boron 0.8%, neodymium 20.2%, praseodymium 13.4%, dysprosium 10.6%, copper 0.8%.

[0129]In the above scheme, the niobium in the main phase alloy can make the crystal grains of the magnet uniform and increase the density of the magnet, so a small amount of niobium added can obviously refine the grains of the alloy, thereby increasing the remanence and magnetic energy product of the magnet; and Aluminum can improve the wettability of the liquid phase and the main phase during the sintering process, make the grain surface smoother, and refine the grains of the main phase, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com