High-speed flat yarn spinning production system

A high-speed spinning and production system technology, applied in the direction of filament/thread forming, textile and papermaking, artificial filament made of viscose, etc., can solve the problem that the twisting basket speed should not be too fast, and the twisting basket equipment is easy to be damaged , low degree of automation control, etc., to achieve the effect of saving labor costs, high productivity, and high degree of automation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

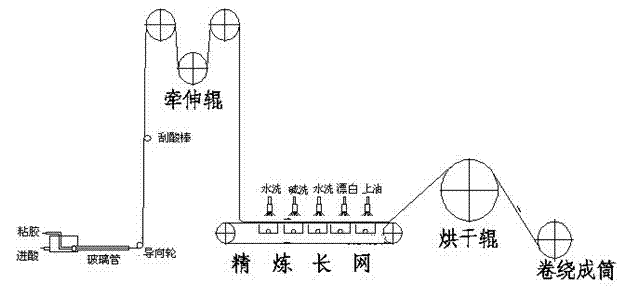

Embodiment 1

[0035] A high-speed spinning production system for flat yarns, comprising a spinneret, an acid inlet box, a glass tube, a guide wheel, an acid scraper rod, and a drafting roller. An acid inlet is arranged at one end of the acid inlet box, and the other end An acid outlet is provided, the spinneret is located in the acid inlet box, the acid outlet is connected to the inlet of the glass tube, the other end of the glass tube is connected to a guide wheel, and an acid scraping rod is arranged above the guide wheel. The acid scraping rod is perpendicular to the glass tube, a drafting roller is arranged above the glass tube, and a post-processing device, a drying device and a winding machine are arranged below the drafting roller; the spinning solution passes through the spinneret under pressure Spinner hole, the fine stream of viscose sprayed out reacts with the acid bath in the acid box to form, and the filaments and acid bath enter the glass tube, and the filaments that continue t...

Embodiment 2

[0037] The implementation mode of this embodiment and embodiment 1 is basically the same, on this basis:

[0038] The running direction of the filaments is consistent with the flow direction of the acid bath in the glass tube.

Embodiment 3

[0040] The implementation mode of this embodiment and embodiment 1 is basically the same, on this basis:

[0041] The running direction of the filaments is consistent with the flow direction of the acid bath in the glass tube.

[0042] The glass tube is at an angle of 3 degrees downward from the inlet to the outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com