A kind of microporous pc/abs alloy and preparation method thereof

A microporous and alloy technology, applied in the field of microporous PC/ABS alloy and its preparation, can solve the problems of restricting the industrial production output of microporous plastics, reducing injection pressure, reducing internal stress, etc., so as to shorten the injection molding cycle and reduce mold clamping. force, the effect of reducing burrs and internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

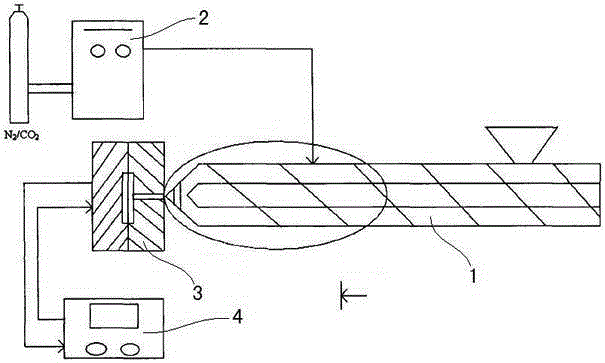

[0023] A preparation method of microporous PC / ABS alloy, comprising the following steps:

[0024] (a) Dry the PC / ABS alloy raw material at a temperature of 80-110°C for 3-5 hours;

[0025] (b) Add the dried raw materials in step (a) into the barrel of the injection molding machine and enter the barrel, and melt the raw materials through heating and stirring of the screw; at the same time, the supercritical fluid used as a foaming agent is prepared by a supercritical fluid constant pressure supply device. Nitrogen is transported and metered by a supercritical fluid delivery device, and the gas is injected for 6-12 seconds, and the supercritical nitrogen is injected into the barrel to form a gas / polymer mixture;

[0026] (c) The gas / polymer mixture obtained in step (b) forms a gas / polymer homogeneous system under the action of stirring and shearing of the screw of the injection molding machine, and is rapidly heated to 200-300°C to make the homogeneous The system produces great...

Embodiment 1

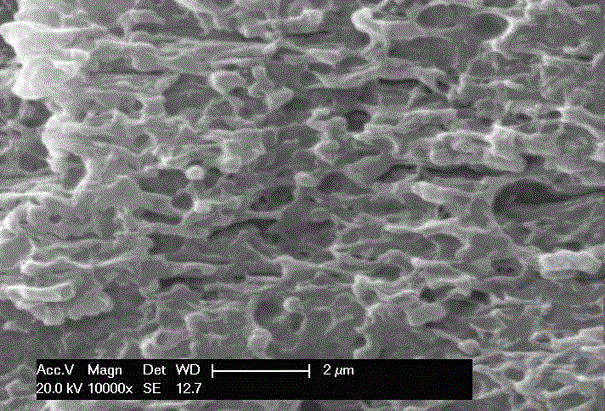

[0030] Example 1 : adopt the above-mentioned supercritical fluid injection molding system, prepare according to the following steps:

[0031] (a) Dry the PC / ABS alloy raw material at a temperature of about 100°C for 3 to 5 hours;

[0032] (b) Put the dried raw materials in step (a) into the barrel of the injection molding machine and enter the barrel, and melt the raw materials through heating and stirring of the screw; the pre-plastic volume is 20 mm; The critical nitrogen is transported and measured by the supercritical fluid delivery device, and the gas is injected for 7s, and an appropriate amount of supercritical nitrogen is injected into the barrel to form a gas / polymer mixture;

[0033] (c) The gas / polymer mixture obtained in step (b) forms a gas / polymer homogeneous system under the action of stirring and shearing of the screw of the injection molding machine, and the homogeneous system is generated by rapid heating to 250°C Great thermal instability, so that the gas...

Embodiment 2

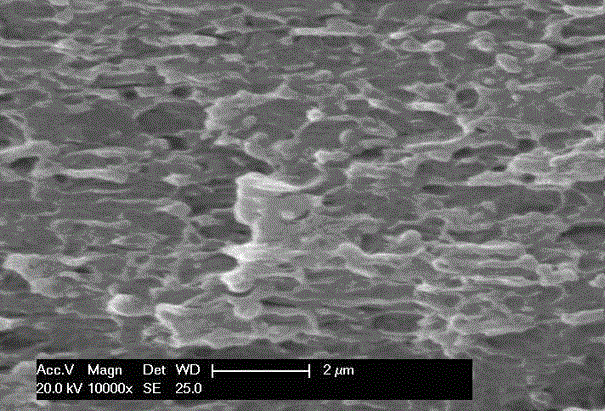

[0035] Example 2 : adopt the above-mentioned supercritical fluid injection molding system, prepare according to the following steps:

[0036] (a) Dry the PC / ABS alloy raw material at a temperature of about 90°C for 4 hours;

[0037] (b) Put the dried raw materials in step (a) into the barrel of the injection molding machine and enter the barrel, and melt the raw materials through heating and stirring of the screw; the pre-plastic volume is 16mm; The critical nitrogen is transported and measured by the supercritical fluid delivery device, and the gas is injected for 9s, and an appropriate amount of supercritical nitrogen is injected into the barrel to form a gas / polymer mixture;

[0038] (c) The gas / polymer mixture obtained in step (b) forms a gas / polymer homogeneous system under the action of stirring and shearing of the screw of the injection molding machine, and is rapidly heated to 280°C to generate a homogeneous system Great thermal instability, so that the gas is preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com