Multi-input/output-port abrasive grain flow turbulent processing device

A technology of processing device and abrasive grain flow, applied in abrasive feeding device, metal processing equipment, abrasive and other directions, to achieve the effect of improving processing quality and efficiency, high polishing accuracy and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

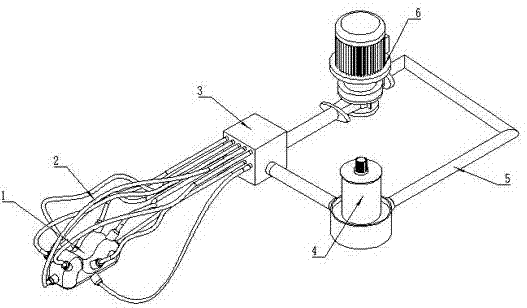

[0016] combine Figure 1~2 , multi-input and output port abrasive particle flow turbulent flow processing device, including a constraint member 1, an electric control valve cabinet 3, and an abrasive particle flow circulation system, the electric control valve cabinet is provided with multiple sets of interfaces, and the abrasive particle flow circulation system Particle flow stirring storage 4, diaphragm pump 6, connecting pipe 5.

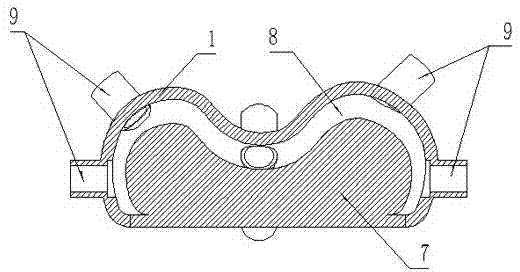

[0017] The constraining member 1 is set outside the artificial joint 7, and a profiling flow channel 8 with a uniform thickness is formed between the inner surface of the constraining member 1 and the outer surface of the artificial joint 7. The constraining member 1 is provided with multiple groups of abrasive particle inflow and outflow inlets 9, and the abrasive particle inflow and outflow inlets 9 communicates with the profiling flow channel 8, and the abrasive particle flow inlet and outlet 9 are respectively connected to the interface on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com