High-frequency and high-voltage electrostatic precipitation power supply

A high-frequency high-voltage, electrostatic dust removal technology, applied in the direction of electrostatic separation, power supply technology, etc., can solve the main harmonics of the circuit without taking any measures, not fully considering the impact, affecting the life of the transformer, etc., to achieve stable long-term operation, The effect of long power supply life and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

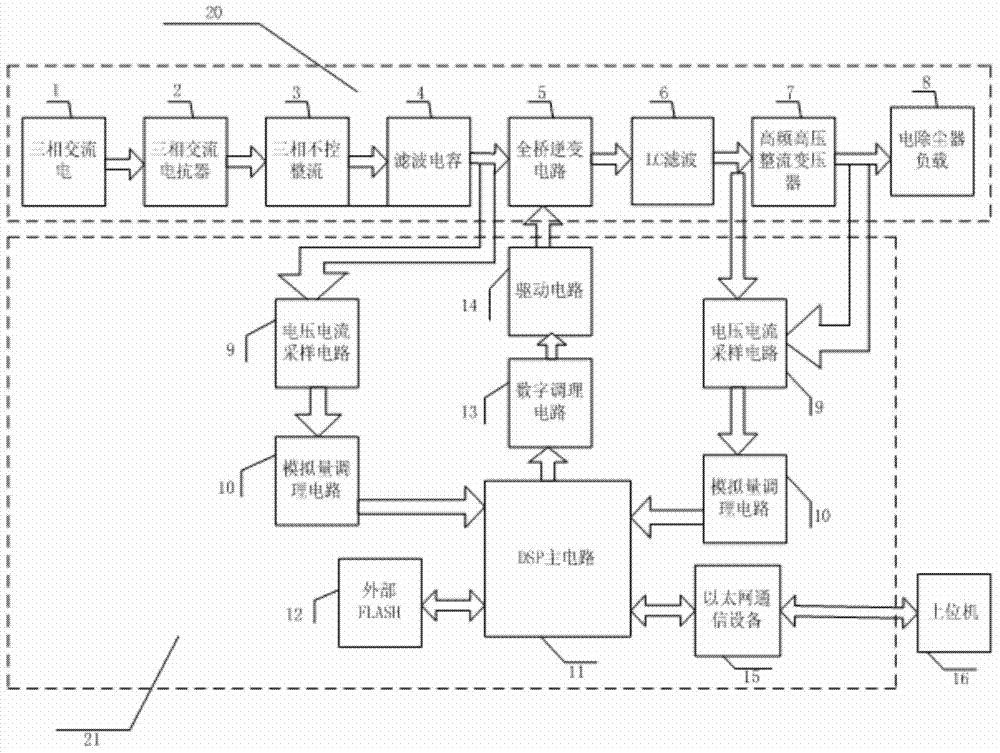

[0013] Such as figure 1 As shown, the high-frequency and high-voltage electrostatic precipitator power supply includes a main circuit 20 of the power system, a control circuit 21 of the power system, and a host computer 16. The main circuit 20 of the power system includes a three-phase AC reactor 2, a three-phase uncontrolled rectifier circuit 3. Filter capacitor 4, full-bridge inverter circuit 5, LC filter 6, high-frequency high-voltage rectifier transformer 7, the three-phase AC power is smoothed by the three-phase AC reactor 2 and then connected to the three-phase uncontrolled rectifier 3, and the filter capacitor 4 is paralleled At the output end of the three-phase uncontrolled rectification 3, it is then connected to the full-bridge inverter circuit 5, and the LC filter 6 is connected in parallel to the output end of the full-bridge invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com